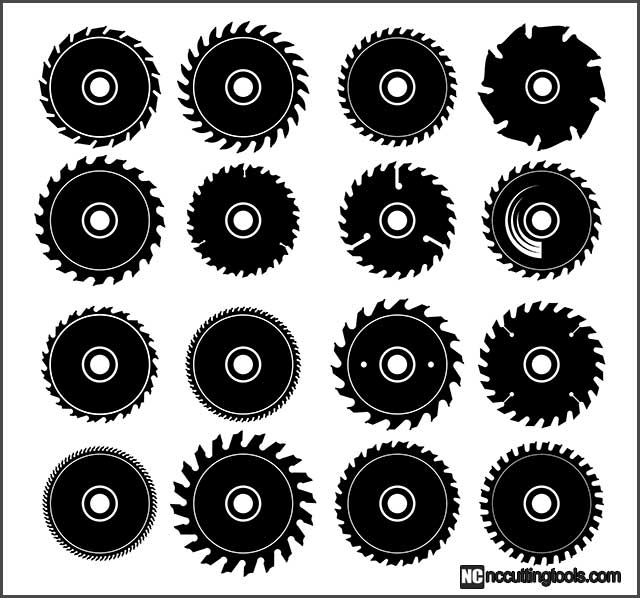

Beyond having that great circular saw which enhances your work, the type of blade you use is also of great importance. Depending on the occasion, some blades can add quality finishing to your work, while others can give you less quality. Thus, to have a high-quality cut, you need to know the type of saw blade that best suits your job.

Choosing the right circular saw blade isn’t difficult as long as you understand the basics. Continue reading as we guide you through tips to choose that large circular saw blade that best suits you.

Table of Contents

- 1. Parts Of A Circular Saw Blade

- 2. Types Of Tooth

- 3. Number Of Teeth

- 4. Diameter

- 5. Material Of The Circular Saw

- Conclusion:

Five Aspects We Will Consider

There are several variants to consider, such as the diameter, material, number of teeth, blade parts, job to be done, and many more. Each aspect that will discuss holds crucial information you need to choose that saw blade that is just right for you.

1. Parts Of A Circular Saw Blade

Let’s continue and get into more details, but before we do, it is best to have a good understanding of the configuration of a large circular saw. With this, you can better choose the saw blade that suits you best. Some of these parts are;

- The teeth.

- The number of teeth.

- The material of the teeth.

- The diameter of the teeth.

- Bore size.

Besides, you must also pay attention to the material you want to cut, as this will determine the type of circular saw blade to use.

One of the important reasons is that the depth at that the blade can cut is synonymous with the diameter of the blade. So also, the thickness of the material to be cut(wood, plastic, ceramic e.t.c.) will determine the blade to use.

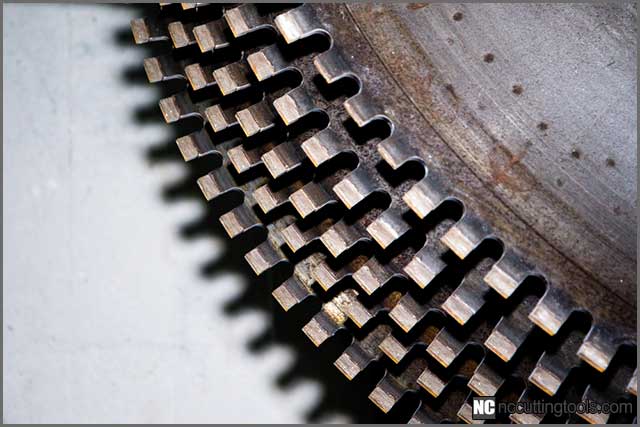

2. Types Of Tooth

To get that large circular saw blade made to your size, you consider the type of teeth the blade has. You also have to consider the angle of attack, of which there are two variants; positive and negative. The angle of attack is negative when the tooth is bent backward, and it is positive when tilted forward.

Analyzing the different types of teeth goes hand-in-hand with the material to be cut to optimize cut quality. Currently, there are several types of teeth for large circular saw blades which can be flat, bevel, or trapezoidal such as;

● ATB Alternate Top Bevel Teeth

ATB teeth cut like a knife and are generally used to cut solid wood, plywood, chipboard, and melamine. They cut in such a way to reduce tear-out. Regarding bevel teeth, an increase in the angle will enhance the quality of your cut while reducing durability. As a result of the type of material we use ATB teeth for, it is more of a general-purpose blade.

FTG Flat Top Grind Teeth.

These types of teeth, as the name denotes, plow through the wood, cutting the wood fibers parallel. It is used in rip blades.

●TCG Triple-Chip Grind Teeth

For the TCG teeth, the edges are beveled, and on the blade, it alternates between bevered teeth and flat-top grind teeth. They are majorly used in situations in which durability is essential. These teeth are more durable than others you will find. They are used on blades meant to cut manufactured materials and melamine boards, as well as used on glue-line rip blades.

●FTG Flat Top Grind Teeth

These types of teeth, as the name denotes, plow through the wood, cutting the wood fibers parallel. You use it in rip blades.

3. Number Of Teeth

As earlier mentioned earlier, the number of teeth of a blade is another aspect you must consider when choosing the right circular saw blade to fit your size.

It is crucial to consider the number of teeth your blade has because the higher the number of teeth, the better the finish. Besides affecting the cut’s finesse, it also changes its speed.

The higher the number of teeth on your blade, the slower the cutting rate of your circular saw. Also, the fewer teeth on your blade, the faster the cutting process of your circular saw. Thus, blades with many teeth are considered plywood blades, with more emphasis on the finish rather than the cutting speed.

Although small-tooth blades are called building blades, they don’t pay as much attention to finesse as speed.

So, if you are a carpenter or looking for a blade that cuts fast while less interested in how your work looks, then go for a blade with little teeth and vice versa.

4. Diameter

As aforementioned, the diameter of a blade determines the depth at which a circular saw can cut, which is why we consider diameter as another determinant in choosing a suitable circular saw blade.

All blades are toothed metals with holes in the middle, referred to as bores. In most cases, it is always safer to use a saw blade with a larger diameter than the saw, as long as you have a hole adjustment ring for mounting the blade on the saw shaft. The blade mounted on the shaft of the circular saw through this hole.

Also, when choosing the right blade for your large circular saw, make sure the diameter of the blade does not exceed the maximum diameter of a blade allowed to be mounted on your circular saw.

But note that if you choose a blade with a smaller diameter, you will be sacrificing maximum cut depth, as a higher blade diameter means higher cut depth.

The blades’ diameter also affects the circular saw’s RPM(revolutions per minute).

5. Material Of The Circular Saw

The material used to make a blade must be stronger than the cut material. So when cutting stones, you do not buy a blade for cutting wood.

Some of these materials are;

●Diamond Blades

Since diamond is the hardest metal on earth, it is used to make cutting blades. In this, diamonds are placed on the blades’ tips give them the ability to cut through stronger abrasive materials such as; concrete stone, ceramics, asphalt, and so on. They are known as abrasive blades.

Carbide Blades

The name for this hard compound comes from metal. Several substances can add to a carbide compound, including tungsten, a hard metal.

Tungsten carbide blades can use to cut plastic, non-ferrous metal, plywood, softwood, hardwood, and many more, including aluminum and copper.

Note: the saw blade remains an essential tool in cutting because you can use the same large circular saw blade for several jobs, but specific blades are needed to cut certain materials. It is why choosing the larger circular saw blade made to your size is paramount for efficiency.

Conclusion:

Large circular saw blades are modern tools important in everyday worship practice. And at such, it’s vital that you understand the types available, how they operate, and other vital things about them. You already know what a good circular saw blade should look like. However, If you need help picking or need a place where you can have access to a quality circular large blade saw made to your size, don’t hesitate to consult us. We supply a wide range of professional guidance and offer suggestions to help you choose.