Most users of the diamond blade often find themselves in a bit of a dilemma. It is not just because the diamond blade comes in several varieties; this is a dilemma that comes after purchase and time into service life. Most users face the question: will this blade live up to the proclaimed quality? And how do I confirm its quality?

All will be able to recognize how different parameters of the diamond blade affect the blade quality. After reading this article, you will know in precise terms the quality of the blade.

Table of Contents

- Chapter 1 Material Hardness (Bonding System)

- Chapter 2 Diamond Concentration

- Chapter 3 Diamond Mesh

- Chapter 4 Blade Shape and Cut Depth

- Chapter 5 Diamond Attachment

- Chapter 6 Cutting Cost and Performance

- Conclusion

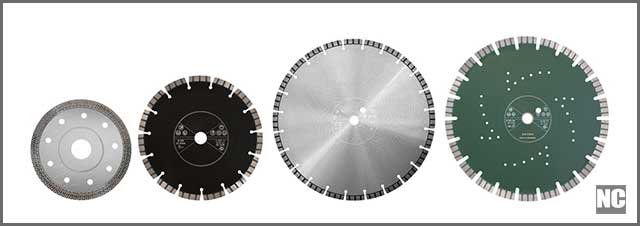

Figure 1: A Set of Diamond Blades

Chapter 1 Material Hardness (Bonding System)

How hard your blade is, says a lot about its quality. Diamond blades are particularly popular for their bond matrix that holds diamonds. How much of the diamond your bond matrix can hold gives you an idea of the quality range of your blade. There are three scales of bond matrix hardness, namely;

• Hard

• Medium

• Soft

Bonds with higher hardness will proportionally have higher diamond retention capabilities. Blades with a harder bond matrix also tend to have a higher life expectancy. This life expectancy is another parameter for blade quality, as blades of top quality last longer. When the matrices of a diamond blade are soft for the workpiece, it will release diamond particles at a fast rate. It causes rapid wear. In contrast, you will notice a slow cutting speed when the bond matrix is too hard. Hence, you will have to dress the diamond frequently.

Chapter 2 Diamond Concentration

Presently in the world today, manufacturing companies of most use both low-concentration diamond blades and high-concentration diamond blades. Both are very efficient in cutting different materials, from ceramics to metals such as stainless steel, titanium, etc.

However, blades with a higher number of diamonds in a high concentration diamond have a slower cutting removal rate. It is because of the friction caused by the contact of the high number of diamonds and the material. The reverse is the case for blades with lower diamond concentration.

Consequently, there is an effect of the diamond concentration on diamond quality. It reflects when the need to dress the blade arises. Diamond-cutting blades of lower quality need more dressing to expose the next diamond layer. Blades of higher quality, however, have a better diamond arrangement in their composition and require lesser dressing to reveal the next diamond layer.

Figure 2: Diamond Concentration on Blade

Chapter 3 Diamond Mesh

You must know that the type of diamond in the diamond blade is synthetic. The reason for this is that the manufacturers can easily adjust the characteristics of the diamond. Customizing these characteristics allows for different blade quality ranges based on price and application. This feature also allows the manufacturer to improve the blade’s service life.

Diamond blades with more diamonds need cutting tools with higher horsepower to operate, making the number of diamonds directly proportional to the power. The diamonds in the segment of the blade vary in quality. These qualities characterize the blade by giving it the quality based on the grade of the diamond to resist heat and its strength.

A significant advantage of the synthetic diamond is the modification of the size of the diamond (Mesh). These meshes range in size from 25-35 or 50-60. The mesh size shows how fine the individual diamond particles are in the blade. For practical applications in areas that require less aggressive cuts, i.e., hard materials like Quartz need smaller meshes, and vice versa for soft materials like asphalt.

Figure 3: Different Mesh Sizes on Diamond Blades

Chapter 4 Blade Shape and Cut Depth

A crucial part of the shape (geometry) of the diamond cutting blade is the “kerf.” The term “kerf” describes the thickness of the diamond blade’s cut as it pierces through the workpiece. Another thing you can also find manufacturers do is classify blades according to their kerf width.

Most users consider the kerf width very important because it can determine the quality of the blade. The kerf reflects on the blade quality because it dictates the blade’s precision level. It goes to say that for projects that require precision, kerf width will matter a lot.

Blades with thinner kerfs often tend to have a different effect on the blade than with full kerfs. Even though full kerf blades have their place, experts prescribe thin kerfs even for heavy-duty saws. Thin kerfs diamond blades often have a faster speed and less heat during cutting. Beyond that, the thinner kerfs also give you a smoother and higher-quality finish. The thin kerf diamond blades also have significant advantages over the full kerf, namely;

• Higher feed rate or cutting speed

• Lower heat generation

• Neat finishing

Another critical advantage the thin kerf diamond blade has is its waste quantity. Users are also wary that full kerfs will produce more waste; a substantial amount of the material will be left as waste.

Figure 4: Thin Kerf Diamond Blade

Chapter 5 Diamond Attachment

There are different methods of joining the core in the design of a standard diamond blade. These methods range in bond or joining quality of the core of the blade, namely;

• Laser Welded Method: this is a popular way of attaching the segments to the core. This method is prevalent because it yields the strongest bond of the segment to the core to date. They are used in applications of heavy-duty machines and deep cutting. Blades of this category are usually thicker, tensioned, and sometimes heat-treated. These qualities enable them to be more flexible.

• Vacuum Brazed Method: This kind of bonding method’s blades are usually cheaper and easier to make. The vacuum brazed is accessible for users carrying dry cuts on soft materials. The production process of these blades is quite simple because they are for less aggressive cutting.

Chapter 6 Cutting Cost and Performance

Manufacturers offer diamond blades at different price points at various quality grades. This quality range spans from standard to premium and then professional quality.

Of all these blade grades, what distinguishes them is their diamond content. As a user, moving from standard to premium quality blades will cost you an astonishing 30 % extra. Moving the professional quality cost way more than the standard and the premium, which are popular in industries.

In the end, you will need to make one ultimate decision whether the quality that you will require is worth the cost. Users with small cutting jobs that require less aggressiveness often go for the standard quality, which is economical. On the other hand, larger jobs will require a blade that can match the requirement for its frequent use. In such cases, users opt for premium or professional quality, which would be less expensive in the long run.

High-end diamond blades come at a pretty steep price, and you can expect to dish out about $700 at the very least. All of this is compared to the type of job each user carries out. So, this isn’t the cheapest type if you are looking for a hobby.

Figure 5: An Operating Diamond Blade

Conclusion

The diamond blade is a cutting tool component that is very common among unskilled and professional users. Most people look to get the best blade that best fits their work description and, simultaneously, is efficient. Many parameters can give you an insight into the quality level of your blade. Features like your diamond mesh and cutting performance all indicate the quality of the blade.

So, as you continue to look out for how to tell the quality of your diamond blade available, look no further; NCCuttingtools is the place for you.