Do you have little or no experience in operating table saw blades? These powerful tool pieces can help you cut wood and other materials of various sizes. To maximize their potential, finding the most suitable table saw blade for your tool is crucial. Look at the guide that will help you pick a suitable tool and blade for your upcoming projects!

Table of Contents

- Chapter 1. Pick Between Maximum Power and Portability

- Chapter 2. How Much Table Space Do You Need?

- Chapter 3. Consider Rip Capacity and Cutting Depth Requirements

- Chapter 4. Always Make Sure Blade and Saw Are Compatible

- Chapter 5. Do You Need a Dado Blade and a Fence?

- Chapter 6. The Importance of Safety

- Chapter 7. How Do You Plan to Collect the Dust?

- Final Thoughts

Chapter 1. Pick Between Maximum Power and Portability

Start by choosing the desired table saw. You can pick between the following three types:

- Stationary

- Portable

- Hybrid

Your requirements are the primary concern when deciding on the saw you need. Do you need a saw to use in your workshop? Would you like to cut big and heavy wood chunks? Or would you like to carry the saw around the house or to other locations to do cutting work?

Stationary table saws are the most advanced tools in this category. They can handle complex projects and cut demanding wood applications. The biggest advantage of stationary saws is power, which enables them to tackle challenging projects. However, their downside is a lack of mobility. Since they are big and heavy, it is not recommended to move them often.

Portable table saws have mobility as one of their key features. You can easily move them around the garage or take them from one job site to another. That is because portable saws are light and compact-sized. However, that also means you can’t use them for large applications since you can’t get the desired precision. If necessary, you can build a large extension table, but the power of the saw is still limiting, so you should steer clear of demanding projects with this unit.

You can also choose hybrid table saws, a mixture of stationary and portable tools. You can mount these to a stand with wheels. These tools are bigger than portable saws and can cut fairly large materials. Additionally, wheels make it simple to move around your garage, allowing easy use and storage.

It is interesting to note that you can also make DIY table saws. Although they can come in handy for simple projects, a professional-grade saw is usually better and safer.

Chapter 2. How Much Table Space Do You Need?

The saw’s power is important, as well as the blade’s compatibility and capability. However, the tablespace is critical to deciding the cutting material size your tool can handle.

Each table saw comes with a working surface of certain dimensions. It is your task to pick the measurements that will suit projects you are working on frequently. For example, a small saw might have a working surface no larger than 19 x 22 inches. The average size of your tablespace should be around 24 x 22 inches. If you go with that size, you will be able to handle most materials and ensure decent precision while working.

However, if you need the ultimate versatility, how about getting large stationery saw with a table that measures 27 x 22 inches or more? If you add an extension table, the size of your working surface can increase to 65 inches.

Extension tables are bought separately, but they are an accessory you might need to work with, particularly large materials. If you are a serious woodworker, you might want to cut large wood pieces occasionally. That is where extension tables come into play. If you don’t purchase an extension immediately, choose a tool that allows you to install one later.

You don’t have to be an expert to install an additional table for your saw. The process shouldn’t take more than a couple of minutes, and you get a generous amount of new space. These extensions are removable, which makes them even more convenient. The only thing to ensure is that you have enough space to place all components of your tool.

Chapter 3. Consider Rip Capacity and Cutting Depth Requirements

When choosing a table saw and a suitable blade, it is important to consider its ripping capacity and cutting depth. Cut it along the wood’s grain if you want to rip a board. It is a very important feature when choosing a blade because the distance between the fence and the blade determines it. The larger the distance, the bigger the ripping capacity of your tool.

However, you might wonder what ripping capacity you need when using a table saw. As usual, that depends on your upcoming projects. For example, choosing at least 24 inches of ripping capacity might be wise if you primarily cut wide boards or plywood. But if you only work with compact-sized materials, you can go with a more modest capacity than that.

When choosing a table saw blade, pay attention to the specifics. The manufacturers might offer two different capacities based on the blade’s side. However, this is a marketing strategy for those not experts in these tools. In reality, the ripping capacity is usually bigger on the right side of the blade due to the way the saw is constructed.

Another thing to consider is the cutting depth you need to make with the blade. The depth also depends on the material you plan to cut. Industry experts consider a 10-inch blade to be a standard size. That blade can handle cuts up to three inches deep. If you go with a 12-inch blade, you increase cutting depth to about four inches.

The depth also depends on the way the tool is constructed. For example, the rising mechanism might affect the rising capability of the blade, which influences the cutting depth. The good news is that manufacturers usually apply a design that maximizes the performance of their tools.

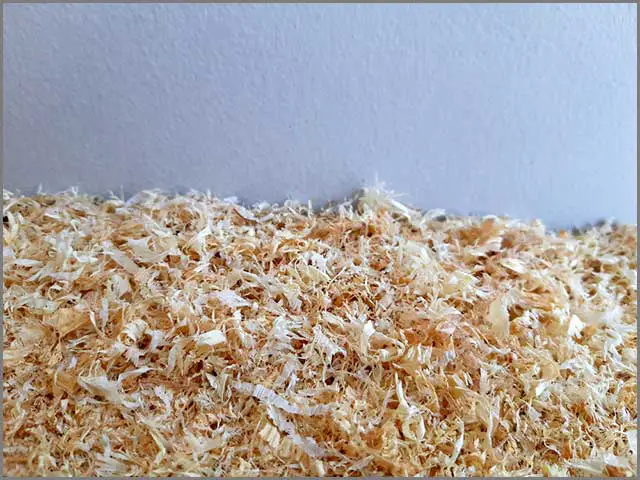

The experts also suggest that dust can decrease cutting depth. If you let the dust collect on the rising mechanism, your cutting depth will decrease, and you won’t be able to cut as deep as before. Fortunately, you can resolve this problem by cleaning the dust collected in the mechanism. Experienced engineers advise regularly cleaning the tool, which can be crucial for your safety.

Chapter 4. Always Make Sure Blade and Saw Are Compatible

We already mentioned that the standard table saw blade size is ten inches. That is the size consumers most frequently use with their DIY and professional tools. However, you will also find table saw blades in other common sizes, including eight, 12, and 14 inches.

The important thing to note is that the saw blade must be compatible with your tool. Look at your saw’s maximum blade capacity, and stay within that specified size. For example, if you have a ten-inch saw, you cannot fit blades bigger than ten inches, which means a 14-inch blade won’t fit. However, you can use smaller blades than the specified capacity. That is why an eight-inch blade will fit in a ten-inch saw.

If you own both table and miter saws, the good news is that you can change the blades between these two tools. That way, you get increased versatility from both tools and save some money.

Another consideration for your table saw is its electrical capacity. The majority of tools work by utilizing 10 to 15amps of power. 15amps is the most frequent choice because amperages lower than that might have problems cutting any materials larger than two by four inches in size. Finally, you should also consider the voltage and ensure it is suitable for the electrical sockets installed in your location.

Chapter 5. Do You Need a Dado Blade and a Fence?

Have you ever used a dado blade? It is a specialized saw blade that you can utilize to cut grooves into the cutting material. The manufacturers stack different blade types together to design a dado. The process is similar to making a sandwich, meaning more components equal a wider groove during the cutting process.

The crucial thing to note is that not all saws support dado blades. The saw must offer a suitable width for the desired cut. Although it depends on the unit, finding a saw with a 0.5-inch cutting width or larger would be wise.

The next thing to consider is whether you need a fence. According to experts, reliable fences make cutting jobs much easier, which is why you should consider using them. If your saw didn’t come with a fence, you could find an upgrade on the market.

The crucial thing to consider is the alignment of your fence. It will affect cutting accuracy, which is your primary reason for using this accessory. That is why it is crucial to properly align the blade and the fence to maximize their performance.

Installing the fence shouldn’t be a demanding process. The simplest fences go on the back or front of the tool and use a knob or handle to place the fence into position. However, the experts suggest using a T-slot fence if you want an easy setup and maximum accuracy. Make sure to choose a tool with steel components to secure optimal stability and sturdiness.

Chapter 6. The Importance of Safety

A table saw blade is sharp, which can lead to injuries while operating. That is why all the necessary precautions to stay safe when working with these tools.

We will discuss two features the experts believe to be crucial in the safety department, and these are:

- Blade guard

- Riving knife

You should use the guard whenever you are operating. The guard’s task is to protect you from any injuries that might happen because of a lack of attention. For example, you might accidentally touch a spinning blade with your fingers or hands, and a split second is enough for a severe injury.

Although experienced engineers do not advise removing the blade guard, you might consider doing it to cut large wood pieces. However, the ease of removal will depend on the tool. Older models of table saws make removal tricky, so you might not detach it in the first place.

However, new saws allow you to remove and reconnect blade guards effortlessly. The manufacturers did this because most users threw away the guard after removing it instead of reconnecting it once they finished cutting large wood. That is why they believed allowing easy (re)attachment is the right way to design a blade guard.

As for the riving knife, the critical thing to pinpoint is that it won’t do any cutting. The task of this safety component is to place it behind the blade. When cutting the material with the blade, the task of the knife is to push apart the cut pieces. Thanks to that, you can maintain accuracy and precision, but it will also minimize kickbacks.

If a kickback happens, the wood will be thrown back at you, which can lead to injuries. You can’t predict a kickback, so minimizing the chances of it happening is crucial.

Chapter 7. How Do You Plan to Collect the Dust?

We discussed how dust collection in the rising mechanism might affect the capability of the table saw blades. However, it is not only about performance but also your health. The scientists revealed that sawdust could lead to breathing and other nasal and long issues. That is particularly true if you are exposed to sawdust for a long time.

That is why it is important to optimize dust collection for your tool. The simplest way might be using a shop vacuum that you would connect to your tool. Additionally, consider cutting outdoors, as that will reduce the number of particles flying around and getting into your organism.

Final Thoughts

The performance of a table saw blade largely depends on its compatibility with the tool. Choosing a blade that will fit your saw is important because that is the right way to maximize its performance.

Additionally, you should consider your upcoming project and the size of the material you plan to cut. Based on that, you can choose a table saw blade size properly, ensuring you get the desired accuracy and quickness when working with the tool.

If you are looking for high-quality Table Saw Blades, check out what NCCuttingtools offers. This customizable mass-sales manufacturer has years of experience and can design blades that meet and exceed your expectations.