Diamond segments are integral to various tools, such as blades and grinders. Whether a beginner or professional, you want to use a high-quality product.

In this article, we will reveal more about diamond segments. Please look at our detailed guide to learn more about these components. You will also discover where you can order high-quality tools at affordable prices!

Table of Contents

- Chapter 1. What Are Diamond Segments, and Where Are They Used?

- Chapter 2.Excellent Heat Resistance

- Chapter 3. Improved Durability and Lifespan

- Chapter 4. Affordable in the Long Run

- Chapter 5. Efficiency Taken to the Next Level

- Chapter 6.No Chips and Cracks

- Chapter 7.Reduced Noise Levels

- Final Thoughts

Chapter 1. What Are Diamond Segments, and Where Are They Used?

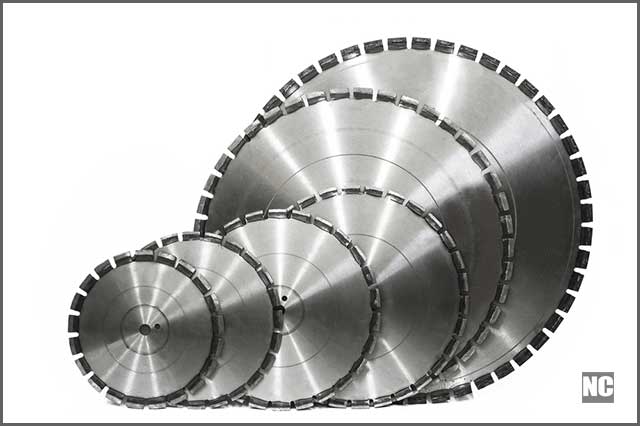

Caption: Diamond disks with diamond segments

Have you ever used a diamond tool? If the answer is yes, you might have checked out its structure. Diamond segments are an important component of these tools. The unique thing about these diamond units is that they are metal-bonded.

The products where you can see diamond segments include drill bits with a diamond core, diamond grinding cup wheels, saws, and other blades.

A single segment contains a tiny diamond part and metal bond components. Copper, iron, selenium, silver, and other metals might be a part of this structure. The manufacturers combine metal with diamonds and then use molds to get the desired shape. Arc grinding, sintering, and cold and hot pressing are methods to achieve the preferred form.

Metals are a part of this structure because they ensure the diamonds remain connected to the tool.

Additionally, they play an important role in the sharpening because they allow the new diamonds to be revealed. The sharpening process is somewhat different for table saw blades and other tools containing diamond components.

A diamond segment has a primary layer designed for grinding or cutting. Many manufacturers add another layer, especially on tools welded with a laser. That other layer only has bonding materials and usually doesn’t contain diamonds. Large blades might have multiple working and non-working levels. Thanks to that design, these units come with improved sharpness while maintaining affordable prices.

What Are the Forms of Diamond Segments on Different Tools?

If you are using a diamond blade, the chances are that the only segments made of a diamond will be the unit’s teeth. The exact shape can affect the smoothness of the cut and the speed at which cutting is possible.

Segments come in various forms depending on the tools used. The primary consideration is the materials the operator will cut or grind. If they plan to work on hard materials, the small size of diamonds with decent concentration should be enough. However, soft materials require a big diamond with a higher concentration. The hardness of the diamonds needs to meet the expectations in both cases.

Chapter 2.Excellent Heat Resistance

Caption: Diamond saw blade with impressive heat resistance

Let’s take a diamond-grinding segment as an example. If you use it, you secure that the hole creates less heat than usual when grinding. That can be critical to avoid overheating problems.

Overheating is an issue that frequently bothers grinding newbies. They often don’t even notice the problem before it causes obvious damage to the application or the tool. That could be an obvious surface crack or burn marks on the materials. If the operator is not careful, they could also burn their hands.

Diamonds can handle high temperatures, which contributes to avoiding overheating. Beginners don’t have to worry about doing anything wrong. Professional and veteran grinders also appreciate diamond segments because they allow the operators to focus on the process. Thanks to that, they could benefit from improved efficiency and cut at greater speeds.

Chapter 3. Improved Durability and Lifespan

Caption: Diamond industrial saw blade with excellent durability

During the talk about lifespan and durability, it is important to consider the wear rate, especially on tougher applications.

The bond of the segment is crucial for determining durability. That bond will wear off slowly and expose new diamonds. These are crucial for maintaining the tool sharp and providing the expected results. Hard surfaces will accelerate the process of diamonds getting dull, but they will still last longer than other non-diamond tools.

The fact that your tool will last for a long time is convenient. First, you won’t have to worry about purchasing new units frequently, saving time and hassle. Even more important, these tools will deliver consistent performance for a long time. It should take a while before diamonds get dull, and they should handle numerous applications before it happens.

Chapter 4. Affordable in the Long Run

Caption: A pile of dollars

Tools that contain diamond segments are more expensive than low-quality tools. That is only natural because diamond units are considered to be of exceptional quality. But when investing in these products, it is crucial to consider long-term expenses.

With a low-quality tool, the chances are the unit won’t last long. Whether it requires frequent sharpening or needs a replacement quickly, durability is not the strongest suit of these products. On the other hand, a single diamond unit can last longer than expected. That will keep you safe from buying new products any time soon. Once you assess all the expenses, you figure out that diamond segments are more affordable in the long run.

Additionally, you need to consider the results of the operation. You can’t put the price on the consistent performance of the tool and admirable results. Smooth and accurate cuts are easier with diamond tools, which you should get for your collection.

Chapter 5. Efficiency Taken to the Next Level

Caption: Sparks flying while machine grinding

We will remain focused on diamond grinding wheels, but the rule applies to any tool containing diamond segments. The form of the segment can determine the traits of the dispersion, as well as how aggressive the wheel will be.

If you find that a leading edge is particularly sharp, it will ensure elevated aggressiveness of the wheel. If the form is tapered, picking the optimal direction will ensure adequate dispersion. All these traits are important to improve the grinding speed.

Diamond segments are tools that can take the efficiency of working with tools to the next level. Efficiency is particularly important in the world of professionals. If you can cut or grind workpieces quickly, you can finish the current project quickly and move to the next one.

Even if you are a beginner, you don’t want to spend more time cutting a single application than necessary. That is why DIY enthusiasts also care about the efficiency of their tools. Diamond segments are there to ensure that efficiency meets everyone’s expectations.

Chapter 6.No Chips and Cracks

Caption: Diamond drill bit used for exploration drilling

You might look for drill bits containing diamond segments because you will work on hard applications. Imagine working with concrete, bricks, or glass. When dealing with these materials, you don’t want to end up with cracks or chips in the application.

The problem with using other drill bits is that they can’t handle the toughest applications. It is why you will end up with debris flying everywhere and cracks in the workpieces.

The chances are that a single piece of concrete or glass material is expensive. You don’t want to damage it, so you must be careful. The safest way to minimize the cutting risk is to use diamond drill bits.

It will ensure a smooth cut that aligns with your highest expectations. You will be delighted with the smoothness and accuracy of your cut, but please note it still depends on the operator’s skills. You must use the tool properly to get the best possible results.

Chapter 7.Reduced Noise Levels

Noise can be a problem when cutting or drilling. If you are drilling in an apartment, the chances are that you might alarm your neighbors. Some drill bits make a lot of noise, while others are quieter. Drill bits with diamond segments fall into the latter category.

It is important to note that you can’t expect a tool to be noiseless. However, if we compare diamond drill bits to others, the data will indicate that these bits are quieter. Even if you are cutting through a tough application, the noise levels won’t be too high. That makes them a smart choice if living in an apartment or other members of your household are complaining about the noise.

Final Thoughts

We hope that our article clarifies diamond segments are a worthy investment for various tools. The only thing remaining is to choose a manufacturer for purchasing those products. It is not always easy to find a reliable company that will respect all your wishes.

That is where NCCuttingTools comes into play. This manufacturer has been around for decades and has years of experience in the industry. The company acquired high-quality equipment and employed knowledgeable and skilled staff. That ensures they can fulfill any order regardless of its details and scope.

NCCuttingTools has a simple ordering process. You can contact the company online and specify your requirements. The manufacturer will notify you of the expected timeframe based on the details. The company has been famous for its fast deliveries and competitive prices for years. If you are looking for high-quality tools, do not hesitate to contact them immediately!