People will tell you that you can cut with any blade. This is true to some extent, but not always. When cutting, you need to consider more than just cuts. You also need cleaner cuts, faster cuts, and even deeper slits. As the demand for the TCT saw blade market increases, finding a saw blade supplier becomes something you need to consider.

The TCT saw blade has crucial features that make it an efficient saw blade. This article will consider the details that make the TCT saw blade essential today.

Facing so many TCT saw blade makers, how should we choose? You need to pay attention to these 8 aspects; after reading this article, you can quickly choose the right TCT saw blade maker.

Table of Contents

- 1. View Manufacturer Network Reviews

- 2. Quality of the TCT blade

- 3. TCT Saw Blade Free Samples.

- 4. Features of TCT saw blade

- 5. Project Customized Blade

- 6. Recyclable TCT Saw Blade

- 7. Certification of TCT Saw Blade

- 8. China TCT saw blade

- Summary

1. View Manufacturer Network Reviews

Choosing the perfect TCT saw blade that fits your job description can be tricky. The reason for this is that you have several manufacturers producing the blade. One thing to do at such a moment is to read the manufacturer’s network reviews.

The present state of the customer supply to the manufacturer is quite complicated. A couple of factors are the reason for this complexity, some of which include connectivity, supplier interdependency, etc. All these factors make the manufacturer’s network susceptible to disruptions on either the local or global level. Therefore, you must check through to see the resilience of the supply chain you are looking to purchase.

Failure to consider and address this particular factor can be problematic. Such problems can leave you stranded whenever you need to change or buy a new blade.

(See network reviews)

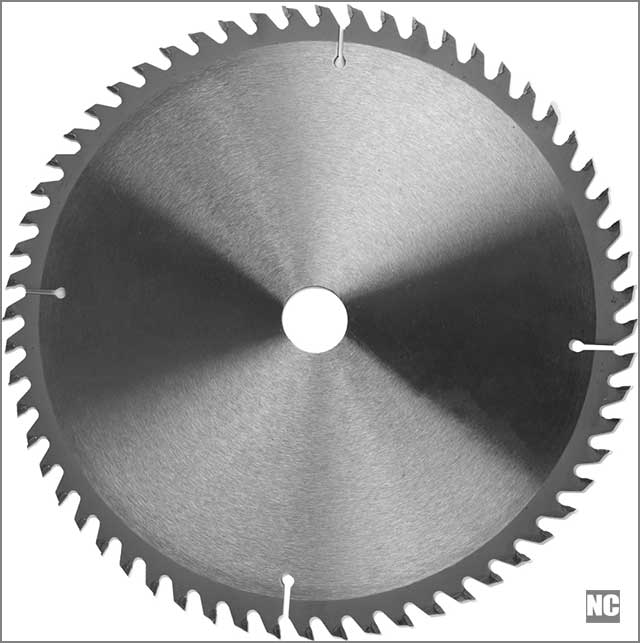

2. Quality of the TCT blade

Another essential tip you will find very useful is the quality of the TCT saw blade. One of the first quality standards you must look out for is the blade’s tip. TCT saw blades are famous for their adhesive feature, and this is because of the silver braze on the tips.

The tooth configuration is another aspect that defines the blade quality. You should look for tooth geometry that can accommodate a range of applications. Your blade configuration must cater to positive and negative rake angles.

The quality of the blade is also evident in the material type of the saw’s body. The shape of the edge must constitute properties that are tough and resilient. The module must be able to support the carbide tip during cutting operations.

So, your typical TCT saw blade consist of a durable material flexible enough to accommodate your project’s working condition. In hindsight, it is vital to note that this might come at a steep price.

Figure 2: A Typical TCT Blade

3. TCT Saw Blade Free Samples.

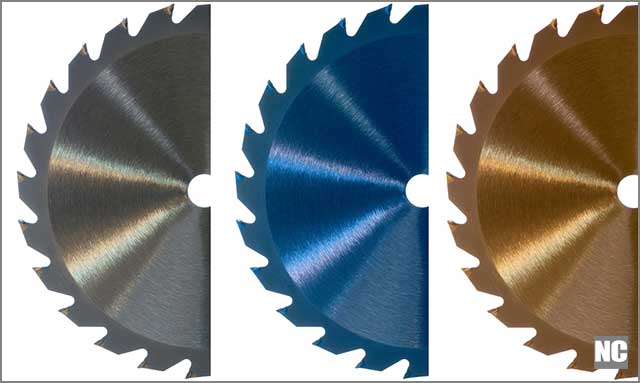

Most manufacturers, to get you to purchase or convince you about their product, give free samples. It gives you a closer insight into the type of TCT saw blade you want to buy. Another reason is that it makes you trust their products more, asides from the benefit of free samples.

The free samples incentive is a tip that will prove helpful when choosing the perfect TCT blade. Beyond this, it gives you the feeling that such manufacturers are willing to go all the way to convince you. It can also indicate that the manufacturers are quite confident about the quality and performance of their products. All of this gives you a good feeling about the blade.

Figure 3: Samples of TCT Saw Blades

4. Features of TCT saw blade

Quite some factors surround your choice of TCT blade. Some of these include the varieties of modules you can use for special functions.

1. TCT saw blade for wood

You can use an industrial-quality TCT saw blade to cut your hardwood and softwood. This blade can also substitute as a crosscutting blade if needed. Such modules have fewer teeth, enablings them to cut along the grain. These blades can sometimes be hardened and tensioned to reduce vibration when cutting.

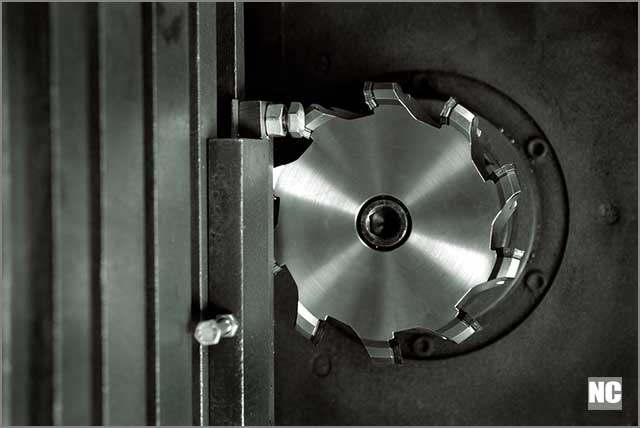

2. TCT blade for cutting metal

TCT blades have also come in variations that are especially for cutting metals. They have structural designs that help reduce contact noise when cutting. These saw blades are most compatible with chop saws, double miter saws, and panel saws. They also have an added feature that gives them longer life spans.

3. Blade Customization

Most manufacturers offer services to design blades with users’ special requests. These types of modules are very flexible enough to match your invitations. Such demands include expansion slots, copper plugs, noise-reduction blades, etc.

Figure 4: A TCT Saw blade in a Mitre saw

5. Project Customized Blade

The TCT blade is an essential tool, so vital that it is an incredibly useful tool, and you will find one in almost every workshop out there. However, it is necessary to note that one of the factors to consider in choosing a blade is your project type.

Choosing the perfect blade for the specific job you are working on can prove quite pivotal. It can determine the situation’s quality and the cut’s speed. You might need to make individual adjustments to the blade to operate at peak efficiency. Specifications like kerf angle, hole size, etc., are some features you can adjust.

So, as you go out to get the perfect TCT saw blade, be on the watch for manufacturers offering such services.

(TCT saw blades with different teeth)

6. Recyclable TCT Saw Blade

TCT saw blades constitute about ninety percent steel. The Tungsten carbide-tipped saw blades have a compound mixture on the teeth that makes it twice as hard as steel. It makes the leaves progressively hard.

Even though you can use the blade to the last, they endure a lot of mileage from their typical use. Eventually, your saw blades should be honed or tossed out. Furthermore, you can sharpen saw blades at home or by taking them to an expert. Be that as it may, you can reuse them if you never again need them.

Since they are made of steel, wherever that reuses metal should take them. Moreover, there are numerous approaches to reusing saw blades. So, as you choose your TCT saw blade, have recyclability at heart.

Figure 5: A Recyclable TCT Blade

7. Certification of TCT Saw Blade

Some bodies certify the quality of a blade and the manufacturers’ validity for producing TCT blades. It is essential because they sign off on such modules for variety, which you should also watch out for in the modules. Manufacturers with quality blades manufacture knives with laser technology. This mode of production is useful when producing leaves of high quality and precision of these products.

Certifications prove a track record of close collaboration with other users and trusted commitment. Such a TCT blade manufacturer is trustworthy and reliable. You can trust such manufacturers to always be at the front of the industry. So, a close association and collaboration with such blade producers will be beneficial.

(Circular Saw isolated on black background)

8. China TCT saw blade

China is no stranger to the production of TCT blades. They are America’s largest competition when it comes to blade production. A top production company of TCT saw blades in China is Jiangsu Yaofeng Tools Co., Ltd.

They specialize in the making of TCT saw blades consisting mostly of steel. They have a factory with state-of-the-art and cutting-edge equipment. They produce TCT blades in all sizes and even take orders for special requirements.

(Artistic TCT saw blade)

Summary

TCT (tungsten carbide tipped) saw blades represent your typical capable blade. The TCT is your go-to blade to get a clean, safe, and accurate cut on your workpiece. Before choosing your TCT blade, you must consider some factors.

Factors like blade quality, blade type, etc. make for a sufficient parameter you consider before choosing.

Ever wondered where to look out for the perfect TCT saw blade? NCCuttingtools is the place for you. With brief and concise information, NCCuttingtools is well-known for quality services and great expertise. You should contact them for more information.