As each year passes by, human beings continue the machinery evolutionary trend. There was a time when all we needed to cut wood was an ax. Now various tools make cutting different types of wood easier and faster. One is the circular saw, which uses a circular saw blade for cutting and ripping wood and other materials.

Circular saw blades can cut through various materials, including hardwood, softwood, plywood, plexiglass, concrete, and more. However, to achieve maximum performance, you must choose the right circular saw blade for each project.

Achieving this might seem impossible, but with proper guidance and understanding, you will have no problem choosing the right circular saw blade.

Table of Contents

- Chapter 1 How to Distinguish Different Types of Circular Saw Blades.

- Chapter 2 Important Factors to Consider When Purchasing a Circular Saw Blade

- Chapter 3 When You Should Replace Your Circular Saw Blade

- Chapter 4 Safety Precautions To Be Taken When Using The Circular Saw Blades

- Chapter 5 Popular Reviews About Circular Saw Blades

- Summary

Chapter 1 How to Distinguish Different Types of Circular Saw Blades.

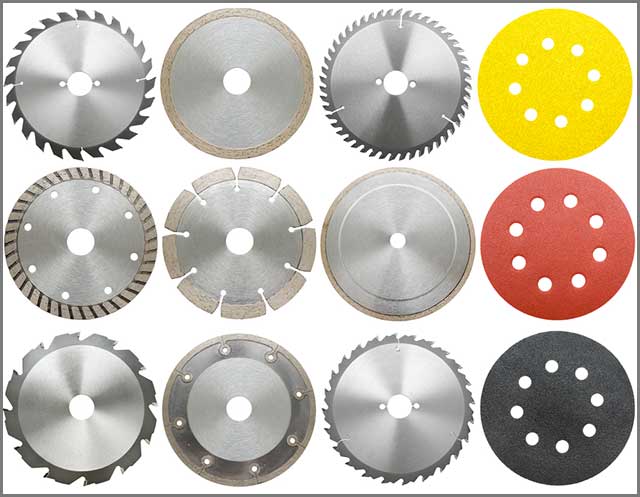

There are various types of circular saw blades. Your first step towards choosing the best and right circular saw blade for your project depends on identifying the different types of circular saw blades and understanding their use(s).

Classified according to the different uses of circular saw blades, including standard circular saw blades used in carpentry works. Abrasive circular saw blades are used in metal works, and diamond circular saw blades are used for masonry works.

1.1 Standard Circular Saw Blades:

According to the word ‘standard,’ they are the blades used in most tasks. They are proficient at wood cutting and come in various modes for different wood-cutting tasks. Some of them are the following;

- Rip-Cut Circular Saw Blades: These types of standard circular saw blades with low numbers of the tooth. Some possess as low as 16 teeth, and some also close in on 40 teeth. This lower number of the tooth allows you to cut aggressively and make larger cuts.

- Framing Standard Circular Saw Blades: These standard circular saw blades are similar to the rip-cut in low tooth numbers. Usually 24 teeth, but it can cut more aggressively and quickly. The rip-cut is the ideal blade when the wood-cutting situation requires volume and speed over precision.

- Crosscuts Standard Circular Saw Blades: These blades have a much higher number of the tooth than the previous two. They usually have between 60 and 80 teeth. These higher tooth numbers allow you to make accurate and cleaner woodcuts.

- Plywood Circular Saw Blades: These circular saw blades have the highest tooth number. Sometimes, more than 100. These high tooth number helps make the finest cut possible with little or no damage to the wood.

1.2 Abrasive Circular Saw Blades:

These are special kinds of circular saw blades. They don’t cut like standard circular saw blades. Instead, they grind due to their disc-like abrasive blades. The materials primarily used to manufacture circular saw blades of this type are silicon carbide and aluminum oxide. They are put to use when working on hard materials like steel, as the standard circular saw blades are not put up for recommendation during these tasks.

1.3 Diamond Circular Saw:

Steel is the main manufacturing material for these circular saw blades with synthetic diamonds attached to them. Masonry engineering is its main application area. It is due to their ability to cut through hard materials like concrete, stone, and tiles.

It includes various types, such as the continuous rim blades and the turbo rim blades, which are similar in that they don’t have a tooth, making them not suited to work on wood.

With you finally understanding the types and uses of circular saw blades, you must know the different factors to consider when making a purchase.

https://youtu.be/FQygqW2xaQE%20

Chapter 2 Important Factors to Consider When Purchasing a Circular Saw Blade

Your choice of circular saw blades depends on the type of job you’re doing. However, there are major critical parts on the circular saw blade that you must look out for before making a purchase. These parts depend on the type of tasks and usage frequency. Your task might require using the circular saw blade daily, occasionally, and often.

The following are the critical parts you should look out for when purchasing.

2.1 Diameter Of The Blade:

This factor determines the tasks done with a particular circular saw blade. It has a close relationship with the depth of the cut. When purchasing, you should choose a circular saw blade whose diameter does not exceed the recommended maximum blade diameter mounted to the circular saw. The depth of the cut depends on this factor. The most common circular saw blade diameter is 7-¼ inches, giving a cutting depth of 2-½ inches.

2.2 Number Of Teeth Of The Blade:

There are circular saw blades with 10 to over 80 teeth. It is important to consider the number of teeth your circular saw blade will have, as it directly affects the speed and fineness of the cuts. More teeth guarantee better cuts but can be slow.

Using fewer teeth on the blade in carpentry tasks would be best because they can cut faster.

2.3 Material Of The Blade Body:

There are various materials involved in the production process of circular saw blades. Understandably, you might wonder why that is. It is due to the point that the material of the blade should be stronger than the material of the item you are looking to cut. The main tool that does the cutting is not the saw; it is the blade, which is why you can use the same circular saw you use to work on wood and also on concrete, but with different blade material. To be safe and achieve the optimum target. You should also look out for the anti-friction coating of the blade material, which prevents the circular saw blade from heating up and gives the blade a longer lifespan, prevents rust, and enables you to use the blade for a long stretch. This coating can be iridium, platinum, or chrome.

2.4 The Material You Will Be Cutting:

A circular saw blade is a versatile tool capable of cutting through various materials ranging from wood to concrete. However, the type of material you are cutting must strictly align with the proper saw blade. Do not use standard circular saw blades to grind/cut masonry materials, nor use abrasive circular saw blades to cut concrete.

2.5 Price:

You can’t purchase a circular saw blade without money. It is why saw blade price is an important factor too. Circular saw blades are available at various prices. Premium circular saw blades usually have components that extend their lifespan and enhance performance. Standard and basic circular saw blades would do the tasks too, but they tend to dull fast and give rough cuts. With this information, make sure you weigh the pros of each circular saw blade with the cost while considering the type and duration of tasks.

Chapter 3 When You Should Replace Your Circular Saw Blade

As an active user of circular saw blades, you should know what factors to look out for that point hands toward replacing your circular saw blades. It is an important factor in your ongoing mission. A dull or worn-out circular saw blade makes your work slow and rough.

You should replace the blade when;

● Pushing your saw to cut through the wood is not going as smoothly as it once did. It shows that the blade is dull/blunt and needs replacement.

● You see excess chips on the wood. Check the blade and see if the chips are in it or if the blade has spoiled teeth and lacks a nice sharp edge.

Chapter 4 Safety Precautions To Be Taken When Using The Circular Saw Blades

Circular saw blades are power tools that should be used with great care and in a suitable environment. So when using these blades, these are a few safety tips you should keep at the back of your mind.

● Ensure that you cut each material with circular saw blades recommended by the manufacturer. It happens by reading the blade manually to ensure you are using the right blade for the task.

● Ensure you wear personal protective equipment when using the circular saw blade.

● Before starting to cut, ensure the circular saw blade teeth do not have any damage in any way or side.

Chapter 5 Popular Reviews About Circular Saw Blades

The blade is exceptional for the DIY enthusiast. It has a solid value for its money. Allows me to get on with my tasks and cut wood easily. – Susan

The circular saw blade is very sharp and very easy to handle. It performed well on several wood tasks. The performance was not disappointing for the price, and I recommend it for small tasks within the house. — Tina

They are great blades; the forked carbide tip is a vital part that produces accurate cuts and moves the wood dust out of the kerf like nobody’s business. ‐ David BB Guns

Summary

Wrapping this up, you now know different types of circular saw blades. Without you losing your train of thought, you understand that you must check the characteristics of your power tools to match that of your circular saw blades. It would be best to choose a circular saw blade according to the material you want to cut. The manufacturer usually provides this information.

It would be best if you also took notice of the number of teeth the circular saw blade you are buying has, as this allows you to specify the quality of finish you desire.

When choosing a circular saw blade for your various projects, you should ensure that the one you settle for can do the task you have in mind or at hand.

We hope you enjoyed our article on “choosing the right circular saw blades for your various projects?” if you have any questions regarding the purchase, samples, and the article, feel free to contact us at https://www.nccuttingtools.com/.