In reality, cold saw blades transfer heat and energy to the chip during the grinding process. It allows them to remain cold. Thus the name “cold saw blades.” As a beginner or intermediate with a cold saw, you wonder how to get maximum results with the cold saw blades. You also wonder how long you need to use it before sharpening the cold saw blades. It is why we set up this article. To hint to you on how to use new cold saw blades.

Table of Contents

- 1. Cold Saw Blade-Apply Correctly:

- 2. Cold Saw Blade-Allow the Blade to Do the Work:

- 3. Cold Saw Blade-Use an Automatic Saw:

- 4. Regulate the Speed of Your Cold Saw Blade:

- 5. Cold Saw Blade-Clean and Lubricate:

- 6. Sharpening Your Cold Saw Blade:

- 7. Take Safety Measures:

- Conclusion

1. Cold Saw Blade-Apply Correctly:

When you buy a new cold saw, use it appropriately. It allows you to prevent it from wearing down prematurely. Solid HSS cold saw blades specifically made to cut stainless steel. TCT cold saw blades are the best used with metals. However, Ferrous metals are harder than non-ferrous metals, allowing you to use TCT ferrous metal cutting cold saw blade to cut non-ferrous metals.

However, you can’t use non-ferrous metal cutting cold saw for ferrous metals. It will wear it down, making your new cold saw blades useless early.

Different cold saws have different recommended operating speeds for different materials. Before using your cold saw for cutting metals or stainless steel, you must consider this. Therefore, choose the proper cold saw blades for maximum performance and longevity.

Figure 1: An image of a cold saw blade used on metals.

2. Cold Saw Blade-Allow the Blade to Do the Work:

When you use a cold saw, it is only proper you know the appropriate force/pressure to exert. It is about the power tool you are using.

When you don’t force the cold saw into metals and stainless steel, you allow it to do its job. It brings so much difference in the blade’s lifespan as against when you force it.

Excess force or pressure does not make a better cut. It only adds excess stress to your cold saw. The teeth might break, or the blade might crack with this. The best way to avoid this is to ensure you follow manufacturer recommendations.

It lets you understand its cutting speed, feed rates, and RPM. This understanding allows you to maximize your cold saw blade performance.

It would be best if you let the cold saw blade do its work without forcing it. Let the cold saw blade rotate at full speed before you start cutting.

Do not add pressure to the blade as it cuts through. All you need to do is pull the power saw forward. Do not overfeed the blade, and holding the saw helps you use the cold saw blade better.

When you let the cold saw blades dictate the cutting rate and set the chip load, you will spend less effort cutting. You would also have good finish quality.

Tight clamping is another way to let your cold saw blades do the work. Tightly clamp your metals/stainless steel in the vise, so it does not move during cutting. The cold saw blade is likely to break if it moves during the cutting.

3. Cold Saw Blade-Use an Automatic Saw:

If you can afford it, you should use an automatic or semiautomatic power saw with your cold saw blade. Compared to a manual saw, an automatic power saw increases the lifespan of your cold-cut saw blade by over 25%.

It does this by reducing the time for cutting metals or stainless steel. With less cut, your cold saw blade does not wear easily.

Also, it is best to use an automatic saw with your cold saw blades as a beginner. They work together to transfer the heat energy to the chip more efficiently than a manual saw.

It is easy to match your cold saw blade horsepower and shaft speed to the automatic power saw. By using the same horsepower, you cut faster.

It is also important you match the blade shaft speed. If not, blade warpage, wobbling, and excessive wear would occur.

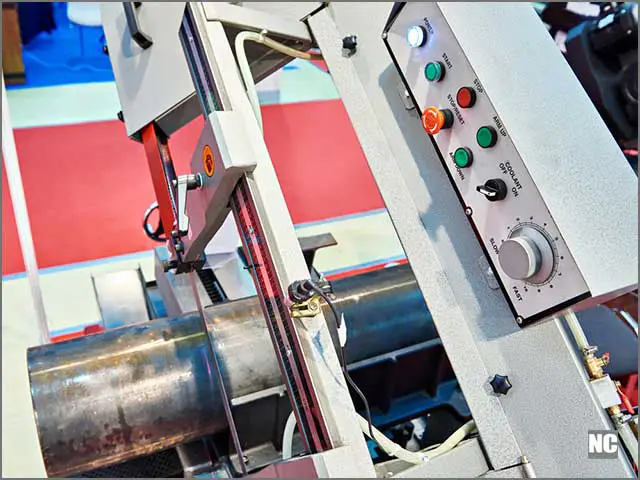

Figure 2: Automatic power machine with a regulator

4. Regulate the Speed of Your Cold Saw Blade:

When you attach a cold saw blade to a power saw with two (2) speeds, regulate it according to the material you are cutting. When cutting stainless steel, use a much lower speed.

When cutting metals, use a much higher speed. The speed list could be surface feet per minute (SFPM) or the regular RPM. Sticking to this speed will increase blade life and cutting ability.

Most power saws have two types of speed (high and low). It would make it easier for you to regulate it according to metal and stainless steel.

It ensures you get a lot from your cold saw blades. Doing this ensures that you tightly bind the blade to the main spindle. You also put the bolt holes against the bolt in the proper direction.

5. Cold Saw Blade-Clean and Lubricate:

Cutting metal and stainless steel with 00cold saw blades and deposits stick to it. You must clean before it makes the blade edges blunt.

When you don’t clean it, deposits harden and form a rough surface on the sides of the cold saw blade. When you cut with these deposits, they cause friction.

It goes on to affect the quality of cuts of your metals and stainless steel. To avoid this, you need to clean the cold saw blade regularly.

Before you start cleaning, ensure to detach the cold saw blades from the power saw. Clean properly with a popular cleaning spray.

Spray on both sides of the cold saw blades and allow it to sit for some minutes. Wipe it off after. It should remove the deposits from your cold saw blades and leave them in good cutting condition.

After cleaning, apply lubricant to it. It prevents the metal of the blade from rusting. Lubrication also helps your cold saw blade make better cuts.

It is why every time you clean, also ensure to lubricate. Be familiar with the warning signs of poor blade performance and excessive wear. It helps you to know when to clean, lubricate, sharpen your cold saw blade or discard it.

Figure 3: Image of a rusty cold saw blades

6. Sharpening Your Cold Saw Blade:

When you use your cold saw to a point where cleaning and lubricating no longer do the trick, you need to sharpen it. Sharpening is a vital part of using cold saw blades.

It is because, when done regularly, it improves your blade’s cutting efficiency and lifespan. However, when you decide to sharpen your cold saw blades, ensure to do it well.

Poor sharpening causes more damage and leads to inconsistent cutting. You need to consider the blade geometry and tolerances when sharpening.

You could give it out to companies rendering sharpening services. They will sharpen it and get it to you in good condition. You could also sharpen it yourself.

It would be best if you do this; you got an appropriate cold saw blades sharpener/filer. Detach it from the power saw when you want to sharpen the blade.

Clamp it in between two planks of wood. Raise part of the saw blade and place the sharpener at an angle where the cutting teeth of the blade are visible.

Pull it back and forth. Repeat until all the teeth have had their turn. You will come out with a cold saw with shiny edges again.

Figure 4: Sharpening the cold saw blades

7. Take Safety Measures:

The cold saw is as dangerous as other saw blades when you handle it carelessly. Always ensure some vital safety precautions to avoid unnecessary injuries and damage to materials.

Wear safety masks and gloves. It is to protect your face and hands from hot flying chips. Checking the clamp while using the cold saw blades is also important.

It helps avoid serious injuries if the clamp is not tight. The cold saw blades should also be put into good storage conditions.

During operation, always direct the cold saw blades away from your body. Strive to maintain a good and comfortable distance always.

Figure 5: picture showing a clamp to hold the cold saw blades

Conclusion

When using new cold saw blades, these tips combine to give optimum results and last longer.

With NCcuttingTools, you find a company with extensive experience meeting customer expectations.

We use advanced technology to provide you with scientific innovations through our collection of cold saw blades. Contact us at https://www.nccuttingtools.com for more information and to do business together.