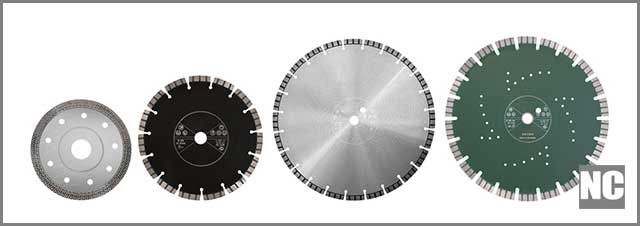

Caption: Cutting diamond discs for concrete

Diamond blades are very durable and reliable, especially when cutting hard applications. Are you in a dilemma about choosing the most suitable rim for your project?

In this article, we are focusing on the continuous rim VS segmented rim showdown. See what you should know about these products and how to pick the blade that meets your needs!

Table of Contents

- Chapter 1. What Is a Segmented Rim Blade?

- Chapter 2. What Is a Continuous Rim Blade?

- Chapter 3.How to Choose a Suitable Blade for Your Project

- Chapter 4. Why Is the Material of the Blade Important?

- Chapter 5. Continuous Rim VS Segmented Rim: What Type of Bond Do you Need?

- Chapter 6. Continuous Rim VS Segmented Rim: What Hook Angle Should You Choose?

- Chapter 7. Continuous Rim VS Segmented Rim: Should You Consider the Gullet?

- Chapter 8. Continuous Rim VS Segmented Rim: Which Saw Blade Lasts Longer?

- Final Thoughts

Chapter 1. What Is a Segmented Rim Blade?

Caption: A segmented diamond saw blade

A segmented rim blade is usually made from diamonds. It can handle hard materials, such as marble, tiles, concrete, granite, etc.

The blade got its name because of the visible segment that it has. Thanks to those segments, it can deal with dust and cutting residue better. The blade is also suitable for dry-cutting projects, which is convenient for two reasons. First, you don’t have to think about how to wet the blade, and you can get straight to cutting. That will also accelerate the process and get you the desired results quickly.

It is, however, necessary not to push the blade over its limits. That might cause overheating issues, which compromise the performance and longevity of the blade. Segmented rims should serve you for a very long time if you use and maintain them correctly.

The cutting results will be accurate and fairly smooth. You might notice some chipping if you are inexperienced or dealing with specific materials. However, their versatility and suitability for the hardest materials make them very useful.

Chapter 2. What Is a Continuous Rim Blade?

Caption: A man cutting concrete paving with a diamond saw blade

If you look at a continuous rim, it will immediately become clear why it differs from a segmented rim blade. You won’t find any segments in the continuous rim, which is why it got that specific name.

The idea of the design that features a continuous edge is to maximize accuracy with hard applications. You can also cut stone, granite, porcelain, and other rough materials with a continuous rim blade. They are particularly suitable for materials that chip easily. By using a continuous edge, the idea is to eliminate any chips and get the smoothest cut possible.

An important difference compared to segmented rims is that continuous blades have a softer bond. That makes them suitable for the roughest applications out there.

The experts recommend using a wet-cutting technique when working with a continuous rim. Since overheating is a common issue, you might try some specially designed continuous blades, such as the one featuring a J-slot design. These can promote the longevity of the blade, improve its durability, and speed up the cutting process while eliminating heat.

Chapter 3.How to Choose a Suitable Blade for Your Project

Caption: Various diamond-cutting discs

The initial step is considering the material that you want to cut. Continuous and segmented rims are both suitable for hard applications. However, if you are going for particularly thick and rough materials, a continuous rim should be your choice.

The next thing to consider is the blade’s size. Although segmented rims are available in various sizes, the most popular diameter is 12 inches, and you will frequently find even bigger blades than that. You should combine circular, concrete, and masonry saws with this blade.

The sizes are the same for a continuous rim, which means you can find a diameter as big as 14 inches. However, you will frequently encounter these blades with a five-inch diameter, which makes them suitable for handheld grinders. Big continuous rims, however, are more than suitable for tile and circular saws.

Chapter 4. Why Is the Material of the Blade Important?

Caption: Cutting concrete floor with a saw

The material of the blade is important because it directly affects the suitability of the blade for particular materials, as well as its lifespan. You can find blades of various materials, but we will discuss continuous and segmented rims. After all, these are the focus of our article.

Segmented and continuous rims are both diamond blades. Now, if you thought these were the diamonds used for engagement rings, you are wrong. That would make each blade extremely expensive.

It is why the manufacturers found an alternative in synthetically-made diamonds. The manufacturing process of these diamonds includes treating them with extreme temperatures and pressure to strengthen them. That way, they are suitable for cutting hard materials.

Now, durable steel is usually the preferred material for the blade itself. The manufacturers attach the diamonds with sintered metal powder or another material.

The overall quality of the blade material determines how you can use it. It will also affect how long it will last. That is why you want to pick a reliable and trustworthy manufacturer to design a high-quality continuous or segmented rim blade for your needs!

Chapter 5. Continuous Rim VS Segmented Rim: What Type of Bond Do you Need?

Caption: Diamond discs close-up

The bond is the attachment type used to connect the diamonds to the blade. While the sintered metal powder is preferred, you can also find different bond levels. You can find a soft, medium, and hard bond depending on the approach.

Your choice of bond will depend on the application you want to cut. Continuous rims usually use soft bonds. While you are cutting, these expose the diamonds quickly. That means you can rely on diamonds for even the hardest applications.

If you plan on cutting extremely hard materials like granite or stone and want a smooth cut, look for a continuous rim with a soft bond. While soft bonds deliver excellent results, fast diamond exposure affects their longevity. The diamonds will wear off quickly, which limits the blade’s lifespan.

You can also use continuous rims with medium and hard bonds. These bonds reduce the diamond’s wear rate, which extends its longevity. However, that comes at the cost of not effectively using the blade on the hardest materials. You can still cut applications like concrete, marble, etc. However, you might face more chipping and should avoid particularly thick materials.

The advantage of medium and hard bonds is the blade’s durability. If you are looking for a blade that will last for a long time, pick a bond that is as hard as possible. But if you want a perfect cut, go with soft bonds. Just be aware that they will wear out quicker than the hard bond counterparts.

Chapter 6. Continuous Rim VS Segmented Rim: What Hook Angle Should You Choose?

Caption: Using a saw blade on brushed concrete

A blade featuring teeth will have those teeth at a particular angle. The angle can be negative or positive. If the angle is positive but stays within ten degrees, the blade will be suitable for chipboards, plywood, MDF, and similar materials. A higher angle will speed up the feed rate, but the accuracy might be compromised.

If you want ultimate control, pick a negative or neutral hook angle. That way, you will reduce the blade’s speed, which puts you in control. If you are dealing with melamine or laminate, that will ensure the desired results.

Chapter 7. Continuous Rim VS Segmented Rim: Should You Consider the Gullet?

Caption: Circular saw gullet close-up

Look at a segmented blade and notice the space between the teeth. Professionals use a special term for that space, called the gullet.

The gulled is important because it can deal with chips and cutting residue efficiently. That way, they ensure the blade can work continuously and without clogging. It contributes to accuracy and smooth cutting results.

Gullets eliminate sawdust efficiently and ensure you don’t have to frequently stop to clean the blade. At the same time, that means you don’t have to use a wet-cutting technique to get rid of the residue and prevent overheating. Gullets offer overheating protection, although cooling down the blade and the application do a better job at that.

The gullet size determines the dust that they can eliminate. The bigger the gullet, the larger the dust it can get rid of during the cutting process.

Chapter 8. Continuous Rim VS Segmented Rim: Which Saw Blade Lasts Longer?

Caption: Diamond-cutting discs isolated on a white background

Regarding durability, the crucial thing to note is that both continuous and segmented rims are quite durable. They won’t wear off quickly, and they can handle frequent use.

However, segmented rims take the win if we compare the two blade types. That is because they have a hard bond that prevents the diamonds from wearing off quickly. Thanks to that, you can rely on the blade to provide consistent results for a long time.

On the other hand, continuous blades use a soft bond, but that is for a reason. Since diamonds do the cutting, the thickest and roughest materials require using them to their full potential. Soft bonds allow that by exposing the diamonds quickly. That is why continuous rims can handle even the toughest materials. However, their durability is not as admirable as their segmented counterparts.

Final Thoughts

Both continuous and segmented rims can perform well and deal with the hardest materials like tile, stone, and marble. Apart from choosing a suitable blade, it is also important to pick a high-quality product. That is where you can rely on NCCutting tools and more than 20 years of production experience this company has in the industry.

The company manufactures a wide range of saw blades for various applications. They employ highly-trained and qualified professionals to work on modern equipment in their factories. The result is the highest possible quality blade products. And the best part is that the blades are available at competitive prices.

Do not hesitate to call NCCuttingtools to discuss your requirements and place an order today!