A cutting tool is a device that removes material by cutting through them, also known as the process of deformation. Cutting tools can be through single-point or multipoint mechanisms.

Deciding on the proper cutting tool requires careful planning and consideration. Getting a project done smoothly and adequately will require appropriate cutting tools. Some specific questions and concerns will arise if you are planning on purchasing one.

If you are unsure what you should consider when choosing a cutting tool, check out the guide below to help you.

Table of Contents

- 1. Select a cutting tool maker in Asia.

- 2. Whether you can provide the materials you need

- 4. Follow the latest cutting tool innovations from suppliers

- 5. Negotiate prices

- 6. Foresee possible transportation problems of cutting tools

- 7. Make sure that your cutting tools have a warranty

- 8. Online shopping is now available nowadays

- 9. Make sure that you are getting from a certified supplier

- Summary:

1. Select a cutting tool maker in Asia.

Many manufacturing suppliers in Asia can give you better prices than those in Europe and the United States. Even companies from the USA and Europe are getting their products from China.

The growth of economies shows that the market for high-speed metal-cutting tool manufacturers is growing quickly. My research indicates that Asia accounts for the highest continent, with an increasing demand for cutting tools.

Relatively cheap labor in Asia also allows you to get preferential prices. And you should pay attention to the quality of the goods while choosing the cheap price.

(Saw for stone)

2. Whether you can provide the materials you need

Sometimes my cutting tool requires a certain kind of unique material that needs to be customized by my supplier. It is essential that before you make a purchase, you talk with your supplier first and specify to him all the things that you need. Before settling with a supplier, ensure that this is the one you can work with to give you all your needs moving forward.

Different types of materials are used for making the cutting tool; these are:

If there are other elements that you need to include in this list, ask your chosen supplier beforehand. And see if the supplier can supply it.

(Cutting tools for quality materials)

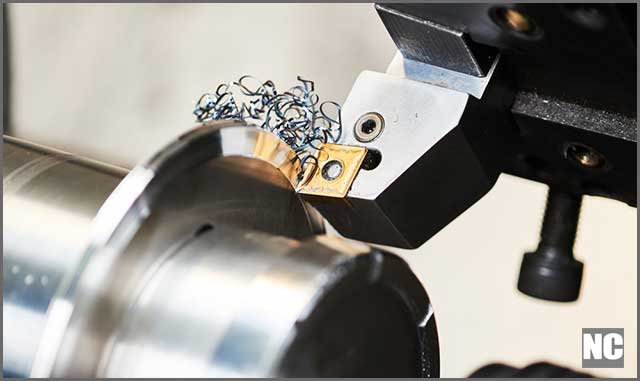

3. Cutting tool production machine

Specific cutting tools will require assistance from production machines to generate high-speed cutting power. The cutting tool supplier that I would recommend is those with a high-powered programming machine that will enhance the cutting power of your tool.

Programming machines are also included. Some cutting tools require modern work assistance to generate high-speed cutting power.

With high-powered cutting tools, the workload gets lighter and more comfortable.

(Industrial engineer engaged in cutting metal and steel with a sharp circular blade compound saw)

4. Follow the latest cutting tool innovations from suppliers

Keeping up with the latest trends is essential when choosing your cutting tool manufacturer. Ensures you have the best and the latest that will give you the service you need.

I know there are many innovations in the field of cutting tools today. Examples of these are

- Carbon-reinforced polymer Fibers are becoming a cutting tool problem today. CFRP is a material being applied in many tools today because of its strength, durability, and wear-tear resistance, making them an ideal article. However, they are posing a problem with cutting tools, which requires manufacturers to level up the strength and power of their cutting tools.

- PVD coatings on cutting tools give them a great advantage. Replacing appliances now and then is a very costly process, not just for us as consumers but for manufacturers. Why are they ensuring the durability of tools as much as possible? PVD is short for Physical Vapor Deposition. This coating increases the performance and productivity of the tools and reduces wear and friction.

- Polycrystalline diamond, PCD, is a powerful cutting tool innovation making waves in the manufacturing industry. Commonly known as the finished product for machining, PCD has incredible durability and is not used for cutting tools.

(Heavy industry workers cut steel pipes with an angle grinder in the workshop.)

5. Negotiate prices

Do not only take things at face value; haggling, But The negotiation process is also a fundamental skill you should use. Before you start negotiating, it is best to draw up a list of the things that are important to you. This list should also include what you are ready to compromise. Always remember to be realistic in your demand.

Haggling should not result in a damaged relationship between consumers and suppliers. Links are significant in business.

Things that you can keep in mind when trying to negotiate are the following:

Understand your supplier

Negotiate with those in power, not on the staff crew who have no authority whatsoever. Do basic research on them and use this as your leveraging power over them. The more you know about them, the better you can negotiate.

Plan a careful negotiating strategy

Consider what your supplier can give you and devise deals that both parties can compromise on that will grant you lower prices while still doing good business for the supplier.

Gater, a negotiating team

Part of a good strategy is investing in people who can do the talking for you if this is not your strong suit. Some people are gifted in this area that can help you more and get you the best deals.

(Discussion of price)

6. Foresee possible transportation problems of cutting tools

Transportation problems are unavoidable when transporting materials, Imported mainly from international manufacturers. Predicting possible circumstances will help you prepare better so that the goods are not damaged.

Here are some things to keep in mind:

Custom regulations

All products require clearance from customs, no matter what it is. You will also need paperwork, one from the country of shipment and the state where you currently live.

Cutting Tools Manufacturers: Custom fees

Fees vary internationally, depending on the product’s price and the country where it is shipped. Products with higher value cost more.

Cutting Tools Manufacturers: Shipping Tariff

The shipping company charges the shipping fee. It also varies on the shipping company that your manufacturer will use.

Cutting Tools Manufacturers: Time of Transit

International shipping takes more time as opposed to local shipment of goods. If you are pressed for time and require the products at a specific date, it is best to work it out at the onset. However, if you opt to have it specially delivered fast, you might need to pay more. Take into consideration here that custom clearance also takes time, so you would need to allow some time for it, too as well.

Cutting Tools Manufacturers: Packaging

It is best to hire a shipping company so you will not have to deal with this. But all packages that are shipped should be packed and labeled accordingly.

Cutting Tools Manufacturers: Medium of transportation

There are two modes of shipment when shipping internationally by land or sea. Airfreight is faster than land travel but also more expensive.

Cutting Tools Manufacturers: Insurance

International deliveries are at high risk for damage. It is best to have your packages insured. Doing this reduces unnecessary financial costs.

(Import and export business logistics high seas transportation.)

7. Make sure that your cutting tools have a warranty

Always make sure that your devices have a warranty. It gives you consumer protection that you are getting your money’s worth. It also gives you the right to ask if the manufacturer cannot produce the expected result you originally agreed to.

(Mechanical turning metalworking cutting tool)

8. Online shopping is now available nowadays

Because of innovation and technological advancement, online shopping for tools has never been easier. With just one click, you can buy from anywhere in the world. Be wary that you are buying from trusted websites.

Please read what others are saying about their products and whether they are a legit company. Proper research will save you a lot of trouble when doing online shopping.

(Laptop on online shopping website)

9. Make sure that you are getting from a certified supplier

The highest standard of certification for manufacturing companies is ISO 9001:2015. Needed to ensure that suppliers are verified and doing business correctly. Companies that are ISO certified are committed to maintaining the highest standard in their industry.

These nine tools are essential to consider upon choosing a cutting tool manufacturer. Select a cutting toolmaker who can cater to your needs and requirements and follows the latest innovation in cutting tool manufacturing. Negotiate prices as much as possible, and predict that there might be transportation problems in the future that might arise. When shopping, you can do this online but be wary of fake companies just looking to take advantage. Lastly, make sure that you are getting from a certified ISO supplier.

(ISO standard quality control guarantee warranty business technology concept.)

Summary:

NCCutting Tools can provide you with all these services and more. They accommodate their consumers’ needs well, and with years of experience in the business, you will never go wrong in choosing them.

They are also ISO certified, ensuring that they follow the industry’s highest standard, which puts you in good hands for all your business transactions.

Call now to find out more!