You can use the diamond core drill bit to punch holes in other devices and holes with different diameters. Besides ordinary concrete, diamond drill bits can quickly cut out reinforced concrete, brickwork frames, steel bars, and other hard structures.

This technology is more effective than other traditional technologies and the most cost-effective method for drilling hard structures and digging the ground. This article introduces eight facts about diamond drill bits to help you better understand the diamond core drill bit.

Table of Contents

- 1. Usage of the diamond core drill bit

- 2. The material form of the diamond core drill bit

- 3. Diamond core drill bit general service life

- 4. The Diamond core bit size selection

- 5. What if the debris gets stuck in the hole?

- 6. Can you use it for tempered glass work?

- 7. Speed control of diamond core bit

- 8. The main advantages of the diamond core drill bit

- Conclusion

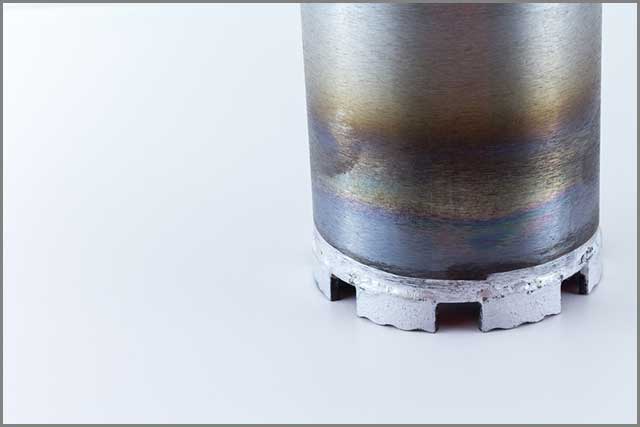

(Blue Diamond core drill bit tool)

1. Usage of the diamond core drill bit

Diamond core drill bits are cutting tools that remove materials and make holes, usually in a circular cross-section. A diamond drill is unique because it can make smooth and neat holes in non-wooden surfaces.

If the name misleads you to think it is a diamond tool, diamond drill bits are not diamond tools. Instead, their parts contain diamond powder. Since diamond is one of the hardest substances to break in the world, you can be sure where this tool derives its name. It implies that it is powerful and can boreholes in almost impossible materials.

Depending on the diamond core drill that you use, you can use it to drill holes in:

• Tough, non-ferrous materials such as fiberglass, ceramics, limestone, porcelain, granite, marble, glass block, quartz, stone tiles, slate, etc.

• Hard substances such as precious gems, bone, hard shells, etc.

In most cases, you can use diamond core drills to perform the following tasks:

- Fix toilet bolt anchors, heating and plumbing pipe holes, and floor-mounted fixtures such as floor lights, bathroom tub, water closet, etc.

- The Fix towel bars, handrails, showerhead holes, curtain rods, stall dividers, soap dispensers, electrical outlets, doors, etc.

- Drilling holes in porcelain tiles, glass drilling for lights, pottery drilling for lamps, china pottery drilling for clocks, etc.

Under no condition should you use electroplated diamond core drill bits to drill holes in hard metals, masonry products, concrete, concrete products, porcelain-cast iron fixtures, and hard stones over 1/2″ deep, amongst others?

(Diamond core drill bit on white background)

2. The material form of the diamond core drill bit

There are two critical types of drill bits: electroplated drill bits and sintered diamond drill bits.

• Electroplated diamond drill bit:

This drill has only one layer of diamond coating on a steel body. You can use this diamond core drill bit to drill holes in softer materials within 1-6 on the Mohs hardness scale. It implies that anything higher than six can cause drill life to reduce.

Using electroplated drill bits on softer and more ductile materials will give you brilliant results with faster drilling action, minimum heat dissipation, and a smooth surface finish.

This drill is a favorite in the glass and composite industries, where its use is not rigorous. It is suitable for occasional use. For instance, you can use it to drill a few holes when installing marble, tile, glass mirrors, etc., in your homes.

For optimal results, it is advisable to use electroplated drills to make holes in materials that are less than 1/4″ thick. It will prevent the practice from wearing out within a short time.

Electroplated exercises are convenient to use for beginners and hobbyists. Avoid using it on surfaces such as concrete or concrete products, porcelain-cast iron fixtures, hard stones over 1/2″ deep, etc.

• Sintered diamond drill bit:

This drill has multiple layers of diamond on the steel shank. It means that, unlike the electroplated exercise with only one diamond layer that peels off after a short period, sintered drills will last longer.

Before and after using sintered practices, it is important to clean with aluminum oxide rock to expose a fresh diamond coat. It gives you the best performance per hole and optimal results.

Although the price of sintered drills is higher than that of electroplated exercises, We should note that the performance of sintered drills is about 20 times that of electroplated diamond drills. Not only will you save money, but you will also save energy and time by using one training to make several holes.

When you peel the coating of the sintered diamond drill, you will get another surface with an even layer for smooth results and performance. The drilling speed is consistent, and the exercises wear evenly, leaving no room for tarnish or uneven drilling results.

(Diamond drilling machine on concrete)

3. Diamond core drill bit general service life

Before you buy your diamond core drill, the essential feature to look out for is its life span. Your customers getting the best service life for their diamond core drill is essential as it determines your profit as a dealer or wholesaler. We have to extend the life of the diamond drill and need to consider some critical issues:

• Pick the right diamond drill bit for the hardness of the material:

When choosing the diamond core drill bit, it is essential to choose the one that fits the hardness of the material you want to drill in. The Mohs hardness scale ranges from 1 to 10. Choosing the one that suits your needs will prolong the service life of the diamond drill.

• Ensure proper flow of water:

Ensure there is a constant flow of water to the bit. Do a routine check of the rods to ensure they do not leak. If the pressure flows appropriately, the drills will be cool.

• Proper lubrication is critical:

Reduction in friction will ensure that the diamond drill lasts longer. Use an environmentally safe lubricant to reduce wear and tear. It will keep the core bit cool and prevent the rods from rusting.

(Diamond core drill bits for drilling holes)

4. The Diamond core bit size selection

Choosing the right core bit size is one of the essential choices you must make when buying a diamond drill. You must consider some factors:

• The hardness of the material you want to drill in: Your choice of diamond drill depends on the hardness of the material you want to drill in. The harder the material, the bigger the size, and vice versa.

• Budget: Your choice of drill bit size relies on the project you want to do and the cost it will incur.

• Speed: For better performance and top speed, choosing the drill bit size that suits your needs is necessary.

(Drilling holes in concrete using diamond core drill bits)

5. What if the debris gets stuck in the hole?

While drilling, you might encounter minor challenges, such as debris getting inside the core. You can get rid of this by drilling your next piece of material, as this dislodges the debris from the center, and you can continue your smooth work. It implies that you should continuously drill into the fabric.

In case the debris doesn’t dislodge after trying the first step, use a wire brush to remove the debris.

(Diamond core drill bits for making holes)

6. Can you use it for tempered glass work?

Using a diamond core drill bit to make drills in tempered glass is highly inadvisable, as the probability of breakage is as high as 80 or 90 percent. The manufacturing process of tempered glass causes a sizeable amount of stress, which causes cracks when drilling occurs. Since you don’t know the pressure the tempered glass is under, drilling holes is inadvisable.

(Diamond core drill bits on a black background)

7. Speed control of diamond core bit

The drill speed of a diamond drill differs from one manufacturer and model to another. Electroplated diamond drills allow for slow speed as the hardness of the material increase. It is an attempt to preserve the lifespan of the tool.

Also, higher rates result in a quicker burn of the diamond bits, which can lead to money and time wastage. By controlling the speed of the diamond drill to suit the material you are drilling in, you will increase the drill bit life.

When determining the drill speed, you must also consider the lubrication and drill pressure. When the drill speed is too fast, the diamond drill will feel warm after use. Extreme heat can cause material breakage.

(Diamond drilling machine for making holes in concrete)

8. The main advantages of the diamond core drill bit

Some core advantages of diamond core drill bit include:

- Low noise: In contrast to concrete core bits, diamond drilling technology is ideal for ensuring high-quality work without noise.

- Produces less dust: Diamond drilling is the cleanest and most environmentally friendly drilling technology.

- Size and shape: You can easily find the size that fits your project to get neat, smooth, and exquisite work results.

- Fast and effective: It saves time, energy and cost.

- You can control it remotely: Mechanized equipment can ensure the safety of workers.

- You can use it for multiple purposes: Depending on the work you want, you can use diamond drills for glass, granite, in optical industries, for underwater activities, to fix things at home, etc.

(Diamond core drill bits on white background)

Conclusion

Diamond core drill bits are of utmost importance as they are powerful and can bore through any surface or material. Now that you have some quality information about diamond core drill bits, you have no excuse not to begin your project.

Are you in need of exceptional quality diamond drilling services? Look no further. At Nccuttingtools, we have professionals with the experience and skillsets to give you the worth of your money and more. Our team uses the most advanced technology to achieve the best results for our client’s projects. Contact us today, and we will make your diamond drilling dream come true.