The diamond drill bit tops the equipment list to give extra care and attention. Why? Because it is necessary for good drilling. The diamond drill bits consist of diamonds that must always be in shape and rigid. The diamonds must be cared for to ensure the drill is sharp and round. So, if you always have to change drill bits frequently, you haven’t maintained them properly. This article will help you with tips for keeping your diamond drill bits.

Table of Contents

- 1. Dressing Diamond Drill bit

- 2. Reduce Friction between material and drill

- 3. Reduce Material Overheating with Coolant

- 4. Sharpening your Diamond Drill Bit

- 5. Storing your Diamond Drill Bit

- 6. Cleaning your Diamond Drills Bit

- Summary

Figure 1: Bottom of a Diamond Drill Bit

1. Dressing Diamond Drill bit

You can do as much as you wish by dressing your diamond drill. This dressing is usually along with the diamond core or the diamond section, and this is because these are the two most common areas of wear in the drill bit. However, you can seldom find wear at the wall thickness. These are the three key areas to watch out for to dress when using your diamond drill.

You can dress your diamond drill bits by using your dressing wheel(preferably the SiC wheel) to dress your drill to the point where the wall thickness is standard.

This dressing helps to expose another layer of diamonds in your diamond drill. After dressing, you will need to resurface the diamonds; as simple as this process is, you must be very careful. That’s why you should resurface with the Al203 stick after dressing.

Another possible part of your diamond drill that you may have to dress is the diamond core. As you dress the core, new layers of diamonds from the bottom make the drill sharper. This drill bottom is essential because it is the part of the drill that does most of the drilling.

Figure 2: Dressing of a Drill

2. Reduce Friction between material and drill

Friction will always be essential when you have moving parts on a surface. In the case of drilling, Friction is also important because the lack of lubricity can cause diamond drill wear.

That’s why you should use water/coolant when drilling. As you add your lubricant, the workpiece absorbs the coolant through the cracks formed by the drill upon impact. This lubricant (water or coolant) in the material will make it weaker and easier to drill.

Your choice of coolant is also crucial because the surface tension of your lubricant determines its effect on the material. As a rule of thumb, you must know that coolants with lower surface tension penetrate more quickly than those with higher surface tension. Besides, some users have also claimed that coolants with a lower surface tension wet the diamonds more easily.

Figure 3: Cooling a Diamond Drill

Overall, it is safe to say that coolants with lower surface tension work better during a drilling operation, both for the drilling and cooling. Lower surface tension also improves material debris lubrication and promotes efficient removal.

3. Reduce Material Overheating with Coolant

Heat energy is a major byproduct of Friction, which can harm your material. The heat generated at the point of contact between the drill and the material must leave immediately.

If this heat gets too much, it can cause graphitization of the diamond drill and sometimes oxidation. This heat also will lead to faster wear on the diamond matrix of the diamond drill.

A prevalent solution to this heat generated is to use water as a coolant. The application of water to the material can be in different forms.

However, the most popular way of applying the coolant is to pump water or coolant through the drill center. This water supply but be sufficient and efficient to always keep the material surface moist for smoother and cooler drilling.

Figure 4: An overheating workpiece

4. Sharpening your Diamond Drill Bit

Drill sharpening is not exclusive to diamond drills but is for all drill bits. This section, however, will discuss the benefits and importance of keeping your drill bit sharp.

The first thing having a sharp drill bit does for you is help manage time. Adequately sharpened and maintained bits tend to operate more efficiently, resulting in faster materials processing. Your diamond drill bits can get more work done in less time.

When your diamond drill gets dull, you must apply more pressure to compensate for the dull drill bit. It isn’t the best thing to do as it reduces efficiency.

Such pressure can cause the diamond drill bits to overheat, further dulling. Ensuring your drill bits are always sharp will also prevent this issue and reduce the risk of damaging your drill. Besides, there is a higher probability of breaking your drill bit when using too much pressure.

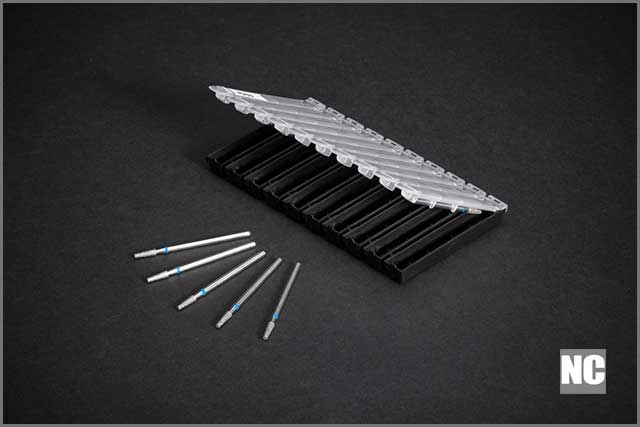

5. Storing your Diamond Drill Bit

As simple as storing your drill bit is, it is highly important because it can significantly increase the life span of the diamond drill. Most drills come with a handy case, and you must do your best always to carry the bit using that case. It would be best if you always kept your diamond drill when not in use to help reduce the frequency of accidental damage.

You must also note that diamond drills must be stored away from water or moisture. This is to stop the drill bit from corrosion and rusting.

Figure 5: Storing your diamond drill bit

6. Cleaning your Diamond Drills Bit

When it comes to the basics of tool maintenance, cleaning ranks highest. In the case of your diamond drill bits, it is not any different.

Now, due to the nature of the drilling operation, it is mandated that you stop every five to seven minutes to wipe off your drill bit with a dry cloth.

Failure to do this frequent and consistent maintenance can lead to drill damage. Now beyond the drill itself, you are also at risk of damaging the workpiece.

It would be best if you topped at intervals because debris is generated while drilling that you must remove immediately. Failure to do this can result in rapid diamond wear through the abrasion caused by the presence of excessive coarse stone fragments.

If you cannot stop at intervals to clean the drill, you must remember to do it afterward. In cleaning after the drilling operation, you are first to allow the drill bit to cool.

After cooling, you can use a towel to clean the drill bit thoroughly.

You can use a dry toothbrush to scrub the drill bit if you have stubborn debris. After cleaning and scrubbing, you can apply a light coat of machine oil to all bits after they

Summary

Diamond drills are cutting tools popular among professional, skilled, and unskilled users. A common complaint by all this category of users is how poor maintenance can severely damage your diamond drills.

This article addresses this issue by carefully providing tips on significantly increasing your drill bit’s service life.

So, as you continue looking for a better understanding of how to take care of your diamond drills bit, look no further; NCCuttingtools has got you covered.

Click for a video with up-to-date information about your diamond drills bit and how to take care of them.