The diamond polishing pad is one of the most versatile diamond tools used in concrete/ marble polishing. They are vital in stone projects and are useful for rough grinding, honing, shaping, and polishing.

However, when selecting, you must pay keen attention to certain characteristics such as type, size, thickness, flexibility, pattern, etc. Failure to look out for these qualities will translate to buying waste of your money and time.

At the end of the reading, you should have extensive knowledge of diamond polishing pads. With this information, the selection of a diamond polishing pad will become easy-peasy.

Table of Contents

- 1. What is a diamond polishing pad?

- 2. Types of diamond polishing pads.

- 3. What is the difference between diamond polishing pads and polishing pads of other materials?

- 4. How to choose the right diamond polishing pads?

- 5. Frequent Q & A

- Summary

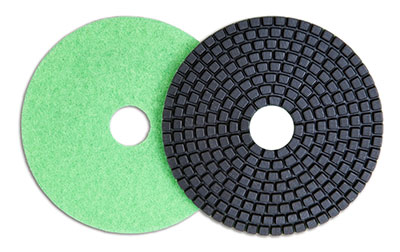

Figure 1: A diamond polishing pad for masonry work.

1. What is a diamond polishing pad?

The diamond polishing pad is a tool that helps to refine concrete, granite, and marble surfaces for a mirror finish. Thus, if you want your surfaces honed, smooth, and without any scratches, you need a diamond polishing pad.

Figure 2: Heavy-duty polishing machine.

2. Types of diamond polishing pads.

2.1 Wet polishing pad

The wetness of these pads keep them cool and prevents overheating and a fast burn out. More so, the water removes waste materials as the surface undergoes polishing.

Wet polishing gives one of the best mirror shine finishes, and it has a lower cost of finish. They also polish various surfaces, including porcelain, terrazzo, marble, quartz, limestone, and granite.

The pads are more affordable than the dry ones. However, wet pads have costlier machinery. Another drawback is that the process is untidy due to the water-based slurry, which could splash during the polishing.

2.2 Dry polishing pad

These pads are suitable for polishing “softer” stone surfaces such as marble, limestone, and travertine. Dry pads need “dressing” before their first use. In other words, you need to run them on something as dense as black granite to expose the diamond.

Dry polishing pads work well on both wet and dry surfaces. Thus, they are equally handy in both fabrication shops and job sites. Dry pads are not messy. Therefore, they are convenient to use.

Another benefit is that they perform well in situations where wet pads do not function well. For instance, they work for smaller jobs that do not need a full wet setup.

However, dry pads produce dust, and there is a need to filter the air you breathe. They also cost more than wet pads and are better for harder materials such as granite and particularly dense concrete.

2.3 Other common types of diamond polishing pads

Hand polishing pads are another type of diamond pad. You do not need to attach them to any tool, and they are useful for cases with a small touch-up.

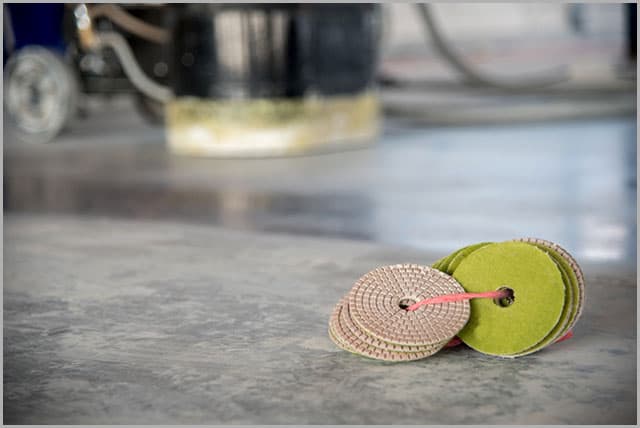

Figure 3: Set of diamond polishing pads

3. What is the difference between diamond polishing pads and polishing pads of other materials?

Diamond pads differ from other polishing pads in several ways. In terms of strength, they contain resin bonds that take time to wear and are strong enough to hold them together. Diamond pads are unique in different ways. First, they are extremely hard and can cut any stone.

Stones that receive polishing have distinct traits. For instance, engineered stones are great for quartz. Unlike these other pads, diamond pads have outstanding irreplaceability, they are more capable than other varieties of polishing pads. Soft stones often clog up polishing pads of other materials and make them difficult to use.

4. How to choose the right diamond polishing pads?

4.1 Which one do we need between the wet and dry polishing pad?

Wet polishing pads give a better finish and are generally more economical. Thus, most people prefer to dry pads. However, since they leave a messy sight, you may need dry polishing pads as a good alternative. Dry pads are a better option if you have limited time and need a fast setup.

4.2 Diamond Quality

Assessing the quality of diamonds in polishing pads could be challenging. However, a rule of thumb is that better quality diamonds, are cut better and receive a better grading.

Accordingly, more diamonds in a polishing pad means a higher cost.

One of the best ways to get quality diamonds is from a trusted supplier. Expensive pads make use of industrial diamonds, while cheap pads make use of low-grade diamonds.

In essence, fewer and smaller diamonds in a pad mean lower quality.

4.3 Binder hardness

Binders hold the diamonds in a polishing pad, and their quality determines the performance and durability of the pad. Thus, binders are extremely vital in polishing pads. Binder materials could be metal, ceramic, or resin, depending on the use.

Soft binders do not last when used to process abrasive materials such as concrete. On the other hand, metal binders perform well for the aggressive removal of materials.

Wet polishing pads mostly use resin binders that are relatively cheap and do not last. On the other hand, dry pads use ceramic binders, which are much better because they resist higher temperatures.

More so, ceramic binders prevent smearing or glazing seen with resin binders.

4.4 Size

Diamond polishing pads with larger diameters give more stability on large and flat surfaces. Thus a 7-inch pad would be much more stable than a 3-inch or 4-inch one. Nevertheless, large pads are not suitable for narrow concrete surfaces. Since they cannot maintain their flatness here, an even cut becomes difficult.

Similarly, larger pads are difficult to apply on vertical edges. Electric or air polishers are mostly suitable for 4 5 –inch pads. In the same vein, small-diameter pads do not provide enough stability for larger surfaces.

Therefore, there is a need to reach a compromise. Thus, a near-perfect size for your pad is 5-inch diameter.

Nevertheless, your choice of a diamond polishing pad’s size depends on the surface you need to polish.

While smaller pads reach remote or inaccessible areas, larger pads are better for the more significant areas.

Figure 4: Large-size polishing machine and pad.

4.5 Thickness

Diamond pads have various thicknesses. However, they range from 2 to 8 millimeters. Thicker pads last longer on average. Nevertheless, they are prone to uneven wear whenever they dry out due to their stiffness.

More so, once a pad wears unevenly, not all of the pad’s area makes contact with the surface. Thus, a 7-inch pad might end up working like a 5-inch one.

Thin pads are not as durable as thick ones, especially when you subject them to aggressive cutting. However, they are more flexible and greatly benefit from honing in curved integral sinks.

Moreover, thin pads are more versatile, and their flatness is easier to maintain.

4.6 The pattern of diamond polishing pads.

The pattern you mold into a cutting surface influences the lifespan and cutting quality. 30 and 50-grit pads (coarse honing) have open patterns with deep and wide channels.

It allows for the quick and effective ejection of the abrasive cutting residue. This method helps to increase the pad’s lifespan when you perform aggressive stock removal.

On the other hand, pads with narrower channels are best for polishing. They clog more under aggressive cutting and when enough water does not flow out under the disc.

Nonetheless, since the 400 to 3,000 grit pads only generate minimal cutting, clogging affects polishing.

4.7 Flexible or rigid pads required

Whether you want to polish a round or flat surface, you need a flexible diamond pad. Most users prefer them to the rigid ones, which only work equally on flat surfaces.

Flexible pads have an excellent performance on countertop edges and sink roundabouts. Thus, except your surface is strictly flat, you should opt for flexible diamond polishing pads.

5. Frequent Q & A

Here are some popular questions asked by hobbyists:

5.1 How long does the diamond pad last?

One diamond pad may last anywhere between 50 and 70 square meters. However, this figure depends on the type of the pad and the surface.

5.2 How much does the best polishing pad cost?

Price is often the first thing that comes to mind when you consider the value of pads. Still, the fact that you have low-priced polishing does not automatically mean it is cost-effective. The best polishing pads may cost up to a hundred dollars.

5.3 Does an aggressive polishing pad mean it is the best?

You might have heard that aggressive polishing pads are the best. While this is partly true, there is more to it. Many factors determine if aggressive pads are the best in certain situations.

For instance, high-production outlets need a quicker polishing process, and aggressive pads are the best here because they do a quick job.

5.4 What do we need to pay attention to in each different project?

Different projects come with unique requirements. However, what you need to pay attention to remains the same. You should know if you need your diamond pad for heavy stock removal, general honing, or a high gloss polish.

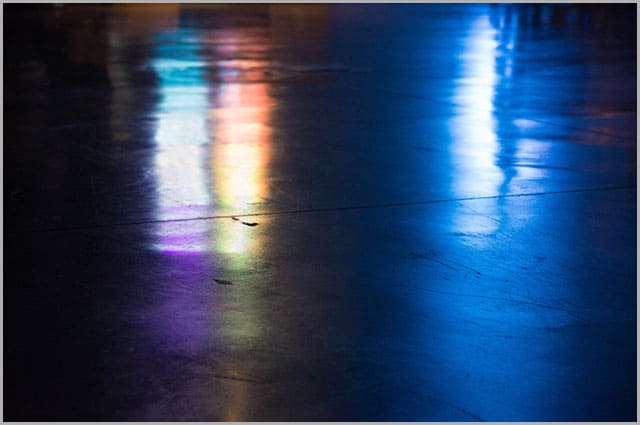

Figure 5: Close-up image of a polished concrete floor.

Summary

Hopefully, you now understand the basics of diamond polishing pads. We have discussed the types, qualities, and differences in diamond polishing pads. Your job becomes more comfortable and faster with the correct diamond pads.

By now, you should know how to choose the right pads for a high-quality finish on your surface. NCCuttingtools provides a variety of cutting tools and customized services just for you. Do not hesitate to reach out to us for further inquiries.