The diamond tile drill bit is an essential tool for drilling hard surfaces. Drilling holes in tiles can be tricky, as you must use absolute caution and the right diamond drill. It would be best if you also understood that ceramic and porcelain tiles are the two most common types.

Porcelain tiles are the hardest to drill, and most of them come with high silica content, making them denser than ceramic tiles.

Not familiar with diamond tile drill bits? Here, we will examine some interesting and unusual facts about these essential tools.

Table of Contents

- Chapter 1. Facts about Diamond Tile Drill Bits

- Chapter 2. Where can you get reliable diamond tile drill bits

- Chapter 3. Frequently asked questions

- Final thoughts

Figure 1 – A handyman drilling a tiled wall

Chapter 1. Facts about Diamond Tile Drill Bits

If you’re looking to purchase a diamond tile drill bit, there are a few facts you would have to intimate yourself with, and we are going to be discussing some of these facts –

1. One size doesn’t fit all.

There are different sizes of diamond drill bits. You are likely to find the standard sizes – 1mm – 3mm, 3.5mm – 60mm, and larger. Now, your tile sizes should influence your choice of drill bits.

However, small diamond drill bits tend to last longer than small diamond core drills, but they take longer to drill holes. Their robust nature allows them to penetrate dense materials such as porcelain tiles and other hard materials.

Small core diamond drill bits, on the other hand, drill holes faster, but they don’t last long due to their small surface area. In all, diamond drills are your best bet for drilling tiles.

As a regular user of diamond drill bits, we recommend having both the small diamond drill bits and the small diamond core drills, as both tools can come in handy when drilling dense materials like tiles.

Figure 2 – Squarehead drill bits

2. You need square head bits.

Most of the time, masons and handypersons drill square holes in wall tiles as they need to affix anchors or holds for bathroom items.

this recurring phenomenon has only gone further to necessitate square head bits. Squarehead bits should be a necessary part of your tile drilling process, as the chances you need them are quite high.

You can also use square head bits to drill rectangular-shaped holes, as they can function well.

So, when next you’re prepping for a tile drilling project, endeavor to add square-head bit drills as part of your drilling tools.

Figure 3 – A mason drilling a tile

3. The lifespan reduces as the coating wears off.

As we discussed earlier, small core diamond drills are fast in penetrating porcelain tiles, but this speed causes the dill tip/bit to wear off quickly, which is quite familiar with drill bits.

In this regard, we recommend that you choose your tools wisely. Tiles aren’t too forgiving, as you can shatter or scratch them easily.

This sole factor is a massive reminder that you shouldn’t use second-hand drill bits for your tile-drilling project or any drill bit for dense materials.

There are diamond tile drill bits available on the market, and we recommend that you use them for drilling dense materials like tiles.

We recommend diamond drill bits because they are hard enough. You should know that making a mistake can be quite costly when training porcelain or ceramic tiles.

On the good side, diamond drill bits tend to wear evenly. With this, you can still drill a perfectly straight hole without the bit slipping away from the aimed spot.

Porcelain tiles usually have a glazed surface due to their high silica content.

4. Drilling at maximum speed causes breakages.

While you may find it tempting to fire up your drill while attempting to break through the glazy surface of your tiles, you should know that this is a sure way to ruin your project; how?

Drilling at maximum speed will overheat your drill bit and cause vibrations that will probably crack the tile. Yes, the glazy surface of your tiles can inspire you to exert intense pressure, but you have to employ absolute caution here.

We advise that you start with a low speed, applying calculated pressure until you have penetrated the glazy surface. Once you have bored through the glaze, then you can gradually increase your speed cautiously.

Once you bore through the tile and hit the wall, endeavor to reduce your rate to not blow the wall apart and cause your wall anchor not to hold properly.

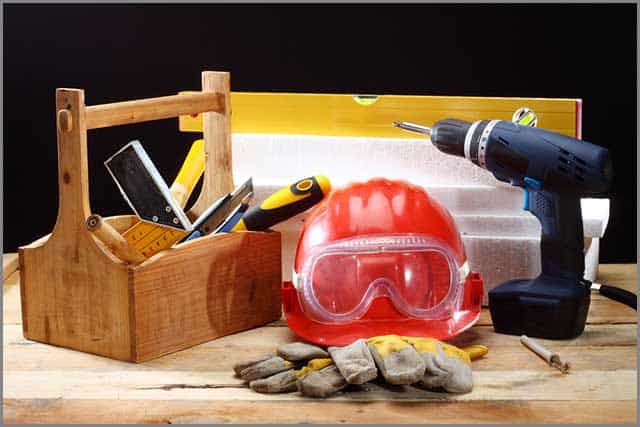

Figure 4 – Drilling safety gear kits

5. Working with diamond tile drill Bits requires extra consciousness

Drilling tiles come with some risk; as such, you ensure that you kit yourself with protective gear. Some of these protective kits include – safety goggles, dust masks, safety gloves, and the like.

Wearing safety goggles will keep fragments or chips of tiles from flying into your eyes during drilling. The dust mask will also keep you from inhaling tile dust.

Generally, diamond tile drill bits are high-speed, and this sole factor can cause your drill bit to overheat. To prevent your drill bit from overheating, we advise that you have a damp sponge close by.

Dabbing your drill bit with a wet sponge will prevent the drill bit from overheating.

Alternatively, you can hold the wet sponge beneath your drill bit while drilling. It will prevent overheating and catch any dust or debris from the intense drilling.

If you’re employing this method, you should be extremely cautious as you won’t want to expose the rotor part of your drill to water.

Chapter 2. Where can you get reliable diamond tile drill bits

Diamond drill bits for tiles are quite specific, and we know their reliability depends on their manufacturers. If you want top-notch tools for your tile-drilling projects, we recommend getting them from NC Cutting Tools, as they are quite innovative in their tool manufacturing.

Also, they are quite multi-functional. It invariably means that you can use them on diverse materials. You can visit NC Cutting Tools to purchase your reliable diamond-cutting tools.

Figure 5 – Drilling a tiled floor

Chapter 3. Frequently asked questions

Well, most of us might have one or two questions regarding diamond tile drill bits. We will be addressing these questions accordingly –

Can I use the same diamond tile drill for all sizes?

Tiles are quite tricky and, most times, require different drill bits. The density and size of your tiles should influence your choice of drill bits. If you’re on a low budget, you can use a universal diamond tile drill bit for your tile projects.

However, you may need to support your drilling with some equipment that will hold your drill bit in place. Support tools or equipment come as part of the package in new drill bits.

Can I use diamond tile drill bits for other materials?

Any diamond drill bit that can drill porcelain tiles successfully can drill similar dense materials. Diamond drill bits for tiles also do well with glass, ceramic, concrete, and other hard materials. So yes, you can use your diamond tile drill bit on other dense materials.

However, it would be best if you were wary of overworking your drill bit and eventually causing it to wear off. Tiles are tricky materials and don’t give you chances to second-guess.

We advise you to have a specific diamond drill bit for your tile projects, as this reduces the risk of shattering or cracking.

Where can I get the best diamond tile drill bit?

Your diamond tile drill bit is as good as its manufacturer. In this regard, we recommend that you get your diamond tile drill bits from NC Cutting Tools, as they have a reputation for manufacturing a range of top-notch diamond-cutting tools.

You can use NC Cutting Tools for a variety of projects. If you’re looking to indulge in any construction of any sort, then you will do well to get your diamond-cutting tools from NC Cutting Tools.

Final thoughts

Drilling tiles is quite a sensitive project that requires absolute caution. It would be best if you understood that your safety matters too, and you can only ensure this by selecting your drill bits correctly.

There are a host of factors to consider when choosing your drill bits. These factors play a huge role in ensuring your safety as well as the successful completion of the project.

While you employ absolute safety precautions, you should also purchase reliable tools. In this regard, we recommend NC Cutting Tools. Why?

It is because they have a reputation for manufacturing the best tools on the market. Feel free to look this up; you’re more than welcome to convince yourself.

You’ll likely find a handful of testimonies from other users of NC Cutting Tools. Join the drilling team by filling your toolbox with NC Cutting Tools.