Whether you are a DIY expert or a professional contractor, a drill is one of the basic tools for most projects you tackle. Apart from choosing a suitable tool for your task, you must also pick an adequate drill bits.

The market offers bits of various types and sizes, and that not be very clear, especially if you are a newcomer to the drilling world. That is why we prepared a detailed drill bit guide. Check out the most common drill bit types, and learn more about their suitability and sizes for various projects!

Table of Contents

- Chapter 1. Twist Drill Bits

- Chapter 2.Masonry Bits

- Chapter 3. Spur Point Bit

- Chapter 4. Bullet Pilot Point

- Chapter 5.Tile Bits

- Chapter 6.Flat Wood Bits

- Chapter 7.Spade Bits

- Chapter 8. Step Drill Bits

- Chapter 9. Auger Bits

- Chapter 10.Drill Bit Sizes

Chapter 1. Twist Drill Bits

Caption: Drill bits isolated on white background

We are starting with the most popular and frequently used drill bits worldwide. Whether you ask DIY experts or professionals, they’ve surely had experience with twist drill bits.

Looking at this piece, you will notice that the front has edges. Their task is to cut through the application. At the same time, the unique spiral construction catches and removes debris. Thanks to that, dust and residue don’t affect your work significantly. It is what makes these bits perfect for timber and metals, plastics, and other materials.

You can use twist bits for both electric and manual drills. The type of material it can cut will depend on how well the drill is constructed. You can choose high-speed steel (HSS) bit, which can withstand extreme temperatures, making it suitable for various applications. These are great for cutting metal and other tough applications.

Carbon steel is another material of choice for twist drill bits. However, it is not as durable, so you might want to try drilling timber with it. If you want to work on metals, consider using bits with a coating made of titanium nitride. That gives another protection layer, which is important when dealing with tough materials.

Twist drill bits are usually not very large, and their size rarely exceeds 12mm. However, they are a great choice for small holes. If you go with thin bits, you can be very precise, and these units allow you to pick the ideal angle easily.

These bits are also convenient for sharpening because you can use oilstone, grindstone jig, and the standard sharpener. Be aware that sharpening might remove the coating of your twist drill bits.

Chapter 2.Masonry Bits

Caption: Concrete drill bit

As the word suggests, you use these bits on masonry materials. They can handle stone, concrete, brick, and other applications because their construction is durable and sturdy.

The secret of their strength lies in a spiral steel shaft featuring tungsten carbide. In some cases, the manufacturers use silicon bronze instead of tungsten for the cutting point.

Masonry bits are primarily compatible with power drills, although you can use them with hand units if you are experienced enough. However, please note that too much pressure damages the pieces, which could break if you use them incorrectly.

The experts recommend using low speeds when drilling hard applications. You should also remove debris and dust regularly. That way, you ensure precise cutting and prevent potential overheating issues. If necessary, stop during the process to allow the bit to cool down.

Regarding sharpening, grindstone and standard sharpeners can do a good job with these bits.

Chapter 3. Spur Point Bit

Caption: A drill bit drilling wooden application

These bills primarily serve to drill wooden applications. While versatility is not their strongest suit, they are an affordable and reliable choice for drilling timber. They are usually not larger than ten millimeters and are easy to work with because of their construction.

You will notice that the spur point bit has multiple spurs on the top. They are raised to help you keep a straight direction during the drilling process. That is what makes this tool suitable for newbies and those who don’t have much drilling experience.

The results that spur point bits provide are usually exceptional. The holes should be clean and smooth, and the bit should provide consistent results. Apart from wooden applications, you can also use it on plastic since that is a lighter material than timber.

As for the sharpening, you will need to use a bit of fiddly to sharpen it by hand, which is a bit inconvenient.

Do you know how to sharpen a concrete saw blade effectively?

Chapter 4. Bullet Pilot Point

Caption: Various drill types and sizes

If you don’t have enough experience, you might confuse the bullet plot point and spur point bits. That is understandable because they look similar due to their designs. When it comes to performance, however, there is a crucial difference. Bullet pilot points are extremely durable and considerably stronger than spur point bits.

That is why this type is suitable for cutting wooden and plastic applications and drilling through metal. The durability of bullet pilot points allows you to cut tough applications. These bits are so strong that you should be careful not to damage your workbench with them.

Bullet points are not only more durable than spur point bits, but they also offer a higher accuracy level. That might come with a price increase, but bits are generally not expensive. One thing to note is that bullet pilot point bits are tricky to sharpen.

Chapter 5.Tile Bits

Caption: Drilling floor tiles in the bathroom

We are now featuring another bit suitable for extremely tough materials. The name tile bit comes for its suitability for tile applications, but you can use this piece for ceramics, glass, etc.

Once again, the reason for the exceptional strength of this bit lies in the tip that features tungsten carbide. It would be best if you aimed to use it on power tools and avoid using hand drills with this unit.

Take a look at more tips on how to choose the right drill bits.

Another thing to note is that you will probably need a lubricant when using a tile bit. Since you are dealing with tough applications, that might lead to extreme temperatures. It is why you must be careful to avoid overheating, and using a lubricant is the way to maintain optimal temperature. Turpentine can do a great job of delivering the desired results.

When it comes to sharpening, you can use oilstone, but please note that tungsten carbide is a strong material. You will need patience and effort to get the desired results.

Chapter 6.Flat Wood Bits

Caption: Flatwood bit in action

Here is an unusual looking, but that is not used that often like some other pieces. A flat wood bit is unsuitable for manual drills, so you should only stick to using it with power tools.

The main advantage of this bit type is that it can produce a flat-bottomed hole. You might not need a circular-shaped hole, but you prefer your hole to have a flat bottom. In most cases, those holes will be large, and this bit can meet your expectations.

The drill bit is suitable for big holes, but make sure that you have a suitable tool to go with it. The piece is a great choice for professionals and demanding projects, especially with specific flat bottom requirements.

However, it would be best if you were careful while working because it produces a lot of fragments and debris. That is why it is important to wear goggles and other protective equipment. You can sharpen the bit using a grindstone or oilstone, and the process is not demanding.

Chapter 7.Spade Bits

Caption: Spade drill bits

If you are not looking for extreme precision and do not need to drill a perfect hole, a spade bit can be a smart choice. These pieces are extremely durable and suitable for drilling rough holes. The tip reminds me of a paddle, and it is very crude.

Even though they are durable, you should avoid using these bits for anything outside of timber. The main benefit of spade bits is their speed. These bits can be very quick if your holes are not visible and hidden out of sight. The hole might be a bit crude and rough, but the piece will do the job, and that is all that matters.

Chapter 8. Step Drill Bits

Caption: Step and cone drill bits

Those who name drill bits usually observe their shape when choosing how to call them. That is why the step drill bit got its name after its appearance, which reminds of shapes. If you move your finger from the top of the drill, it will be like you are coming down the stairs.

Apart from the creative name, the step drill bit delivers versatile and useful performance. You can use these drills for sheet metal, and they can handle various application sizes.

Step drill bits are durable, but their unique construction affects the price. That is why you might expect them to cost a bit more than most other pieces. However, they return that with the highest level of versatility. Since they have various steps, you can choose the size of the hole that you are drilling. This can be an all-in-one drill bit, which justifies the high cost.

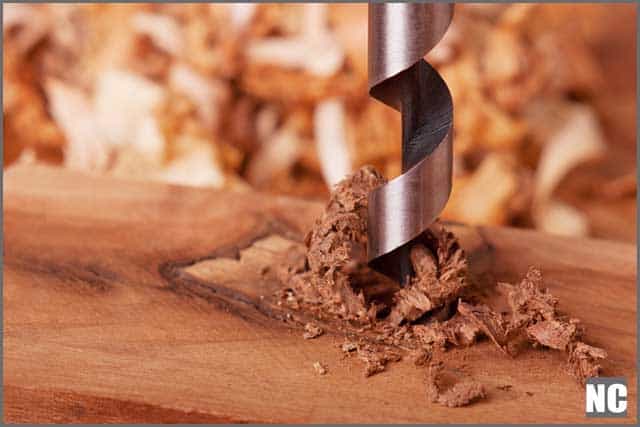

Chapter 9. Auger Bits

Caption: Auger bit drilling wood

These bits are among those that should only use on timber. Auger bits are a great choice for wooden materials that are dry, thick, and hard. That makes them more durable and reliable than classic timber twist bits.

Auger bits are also suitable for drilling big holes. Their specific design will ensure that you can drill all these holes effortlessly. You will notice that the bit has a screw-like thread on the tip. Thanks to that, the bit goes into the application and reduces the effort you need to invest. You won’t need to push; the bit will make a large hole with a relatively smooth finish.

These bits are quite quick and remove the woodchips at a very high rate. That creates a certain level of debris, so you might consider wearing protective glasses.

Chapter 10.Drill Bit Sizes

Caption: Drill bit sizes

Apart from choosing the right type of drill, you also need to choose an adequate size for your tool. You can use the British (metric) standardization or American (fractional) standards, depending on your location or preference.

If you choose British standardization, the size of your drill bit will show in metric measurements. The manufacturers utilize millimeters, and the sizes go from as low as 0.02mm to 25mm.

It is important to note that you won’t find bits of all dimensions between the specified. The industry has already established default dimensions. The good news is that finding a suitable one for your project shouldn’t be a problem.

When it comes to fractional sizes, you will find that the manufacturers often use fractions of an inch. You might encounter 1/8, ¾, or 1/2″ drill bits on the market. The sizes might vary, but it should be easy to find suitable dimensions. Please note that some manufacturers might even choose letters to describe the sizes of their drill bits. Although that is rare, A usually describes the smallest bit in those cases, and Z is the biggest one.

The prices shouldn’t vary (or significantly) based on the size. You can also decide on a customized size; some manufacturers are ready to deliver personalized orders. However, expecting a price increase for all special requests is only natural.

Final Thoughts

Your choice of drill bit type and size will depend on the application. Some bits are suitable for both wooden and metal applications, but you must pick a suitable one for tile, glass, and other tough materials.

Additionally, you want a power tool that can meet your expectations and deliver consistent results. If you need reliable and durable diamond tools, look no further than NCCuttingTools. This company has more than 20 years of production experience and the latest equipment, ready to design high-quality tools that meet industry standards.

On top of that, you can get the best-quality projects at the most affordable rates. Don’t hesitate to check out their offer and place your order today to see why they are a favorite of many worldwide users.