Since time immemorial, man has devised ingenious means for construction works. The constant and conscious efforts made by man towards advancing construction has today yielded immense result. One of these many results includes the advent of saws for cutting any material, such as the glass ring saw. The glass ring saw is a small diameter wire ring designed to spin at high speed to cut glass of form. Although the ring saw can be useful for other purposes, this article focuses on glass cutting using a ring saw.

Table of Contents

- 1. Making Complex cuts and pattern

- 2. Cutting of fused glass

- 3. Cutting very thick glass

- 4. Cutting drapery glass

- 5. Cutting small pieces

- Conclusion

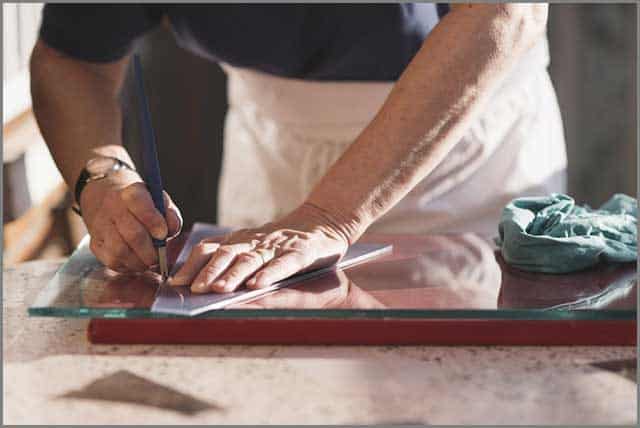

Fig.1: Glass cutting ring saw at work.

1. Making Complex cuts and pattern

After the glass ring saw was invented, cutting off certain shapes and patterns seemed impossible. It is safe to say that the glass ring saw turned the game around regarding glass art. Artists who deal in glass for their craft find it useful to have around. The blade of this saw is made abrasive instead of toothed. Furthermore, the abrasiveness of the blade is due to the coat of diamonds around it. The ability of the ring saw to cut intricate and straightforward patterns is inherent in the blade, cutting in all directions. Forward, backward, left, or rightward cuttings are achievable with the glass ring saw.

Regardless of the industry you belong to, you would find this tool extremely important to your day-to-day work; the round shape of the blade makes it effortless to maneuver when cutting out any pattern of shape on the glass. With the glass ring saw, you need not bother about chips or breaking of your workpiece during cutting. All these have been well taken care of in the design of this great tool.

Above all, this saw helps to achieve highly precise and accurate cuts of any shape. Once you have this saw, making tight curves and cuts becomes easy-peasy.

Fig.2: Picture showing irregular shapes of stained glass.

2. Cutting of fused glass

Before going further, let’s briefly analyze how pertinent a glass ring saw is to cutting fused glass. We must examine the technology behind fused glass itself. If you are wondering what fused glass is, it is made by melting different pieces of glass at high temperatures, up to 820 degrees Celsius. Once these glasses have been melted together and formed rightly, how to cut and avoid breakage comes into play.

When setting out to produce this fused glass, manufacturers should consider the constituent glasses’ compatibility. Manufacturers often perform tests to determine the compatibility of the glasses they intend to fuse before commencing. The importance of this test helps to determine the strength and integrity of the final product.

Having picked your preferred fused glass for your project, you need to cut it to shape. If you are a glass art enthusiast, the glass ring saw is a must-have. Rightly investing in equipment such as a glass ring saw is a great plus for you as a glass artist.

Generally, always be careful when using glass. Most especially, fused glass to avoid breakage. You, therefore, need to have the best glass ring saw at your disposal if you desire to excel in this field. Owning a glass ring saw will save you a lot of stress, increase your efficiency, and give your accurate cuts.

Fig 3: Marking-out on glass in preparation for cutting.

3. Cutting very thick glass

What comes to mind when you hear very thick glass? Thick glasses are known for their application in both residential and industrial/commercial purposes. In some cases, you can call them heavy-duty glasses. Cutting this type of glass with the glass ring saw blade has never been easier. Below is the range of glass thickness mass-produced with their specific purpose-

3/32″ (2mm)- known for picture framing.

1/8″ (3mm)- For end tables, windows, picture frames, and insulated units.

3/16″ (5mm)- Shelves, small tabletops, insulated units, etc.

1/4″ (6mm)- For protective covering on tables, insulated units, paned windows, shelves, and shower doors.

5/16″ (8mm)- usage is similar to 1/4 inch but not common in the US market.

3/8″ (10mm)- For office portioning, walls, shower doors, handrails, used in shower doors, tabletops, glass walls, glass partitions, bars, door lights, etc.

Of all the thicknesses listed above, the thick ones range from 3/8″ up to 1″. Over time, thick-tempered glasses have found their way into the heart of architects and designers. The 3/8″, 1/2″, and 1″ are often used for retail stores, modular offices, tabletops, reception desks, etc. The reason for adopting thick glasses for this purpose is not far-fetched, as cracking must not occur at all.

In this case, cutting thick glass with a glass ring saw is essential if you are in this business or industry. The diamond coat around the blade enables it to conveniently penetrate the depths of thick glasses. Consider purchasing this glass ring saw to help you pull off smooth cuts on these extremely thick glasses.

Fig. 4: Set of glasses with varying thicknesses.

4. Cutting drapery glass

This type is different and unique, unlike other glasses in the previous section. Whenever you come across a cloth-like, well-folded, and wavy glass usually associated with uneven thickness, then it’s a Drapery glass. Drapery glass has its front and rear side not equally thick, meaning it’s not flat. It could significantly affect the cutting and overall ease of handling this glass.

A glass ring saw befits this purpose due to its ability to cut in any direction in a bid to cut properly. Often, this glass is fused and stained in nature; i.e., it is a product of different melted glasses with different colors, which makes it stained. For this reason, before advancing to cut this glass, you must score the pattern with the saw. Scoring involves making an initial outline of the pattern you want to cut. Scoring the glass helps avoid any possible breakage or chip falling off the edges.

As you set out to cut, you need to observe the following features of the drapery glass. Firstly, on the front of some drapery glass, the folds appear to be reversed while the rear is hollow. In other cases, the rear side is flat, and the folds are on the front with visible thickness in places.

Secondly, after carefully classifying the nature of the drapery glass, you must cut from the surface with the least irregularity. Watch for the drapery glass’s reverse side to mark your pattern over the drape’s front side. More irregularities imply thicker glass, which makes it more challenging to cut than a flat side or lesser irregularities.

Thirdly, position your glass so you can easily cut the proposed pattern. Lastly, ensure you score the outlined pattern before fully cutting with the glass ring saws.

Note that you need not polish your workpiece with the glass cutting ring saws as the cut is always perfectly executed.

5. Cutting small pieces

Here, the glass ring saws have many advantages due to their design. The tabletop attached to the saw makes it easy to cut extremely small glasses accurately. Again, tiny bits of glass has proven to be a valuable asset to a glass artist. Mosaic artists find these small bits of glass useful as well. They cut out small pieces from off-cuts or large sheets of glass. You can decide to decorate with small glasses. You can also opt to join different tiny bits into an artwork. Glass ring saws can cut your glass into sizes; even a handheld cutter cannot achieve this. Over the years, many glass artists and enthusiasts have attested to the relevance of glass ring saws.

Fig.5: Picture showing broken and small pieces of glass.

Conclusion

In this read, we have discussed the cuts possible by the glass ring saw and considered other factors. Regardless of the glass-cutting project, be assured of the appropriateness of the glass-cutting ring saw any day, anytime. Building construction professionals do not take the glass ring saw for granted in their day-to-day activities. The importance of stained-glass ring saw cannot be over-emphasized, whether as an artist or a small business owner involving glass. It would be best to allow the blade to do the work, not force it. Do not hesitate to contact NCCuttintools. We remain committed as a foremost solution provider of cutting tools and accessories. Our knowledge and experience of over 30 years remain pivotal to our relevance to date in this industry. Do check out this video if you require further guidance in using this excellent tool.