Drill bits are essential tools that manufacturing companies use for their daily activities. These companies use them in drilling holes through diamonds, metals, woods, and other surfaces. However, there’s ever an on-going argument between the two of the most dominant drill bits – High-Speed Steel HSS and Cobalt Drill bits. Drill bits distributors, suppliers, and users alike struggle to understand the differences between two very similar drill bits.

Thus, this article will expose you to everything you need about HSS and Cobalt drill bits, their similarities, differences, and applications.

What are the drill bits?

Before we dive in, let’s take a moment to get familiar with what drill bits are.

Drill bits are essential tools that diamond manufacturers and other companies that deal with hard materials use to create holes, usually circular cross-sections into surfaces. These cutting/drilling tools come in various shapes, sizes, and lengths. They work alongside drills to generate the power they need to drill a hole into a workpiece using rotational motion.

Table of Contents

- 1. Drill Bits Classification Depending on the Materials

- 2. What are HSS Drill Bits?

- 3. What are Cobalt Drill Bits?

- 4. HSS Vs. Cobalt Drill Bits

- Summary and General Suggestions

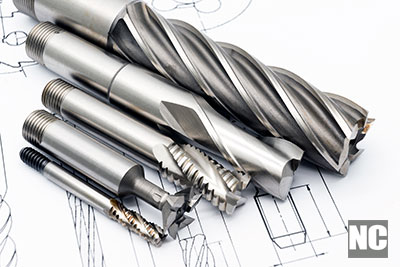

Figure 1: Professional multi-flute cutting drills for metal works.

1. Drill Bits Classification Depending on the Materials

There are various ways to classify drill bits. However, the scope of this article will be classification using materials. Other materials exist, but our sole focus will be on the duo of high-speed steel (HSS) and Cobalt drill bits.

Before we dive in, let’s briefly define what HSS and Cobalt drill bits are.

Figure 2: Making a hole into a wood with drill bits

2. What are HSS Drill Bits?

HSS drill bits are commonest drill bits so far. They combine carbon steel with other elements, including chrome and vanadium. It’s a multipurpose tool works seamlessly on surfaces such as iron, steel, aluminum, brass, and copper. You can equally use them on plastic and wood if the hole size is minimal.

The high-speed drill offers excellent precision when drilling metal. Also, with the self-centering angles, there’s no fear of wandering. With the precision ability of high-speed steel, you can generate 40% quicker drilling at 50% lower feed pressure.

High-speed steel derives its hardness from its structure containing iron and carbon and the addition of alloy at 5% and above.

Forms of High-Speed Steel

HSS comes in multiple forms depending on the materials used to manufacture them. Two notable examples are tungsten and molybdenum HSS.

You can use molybdenum HSS tools in operations that involve low speed and high feed that produce stress from complicated tool shapes. M42, for instance, is useful in works that require a perfect mix of strength and harness with low cutting speeds. M42 provides superior hardness than M2 but doesn’t offer its hardness. Also, M2 works perfectly in operations prone to chipping at the edge. However, for burning tools, M10 is the ideal HSS drill bit.

Also, there’s premium HSS (HSSE) that possesses more percentage of vanadium and tungsten carbide steel. It functions similarly to the ordinary HSS but offers more durability and resistance to wear. However, it’s more expensive than the regular HSS, an attribute that makes it less desirable to tool users.

Application of High-Speed Steel Drill Bits

HSS’s superior features, such as high heat resistance and durability, have seen them replace carbon steel in several applications.

It’s highly useful in applying many cutting tools, such as saw blades, milling cutters, gear cutters, taps, jointer blades, tool bits, and many more. Also, HSS is ideal in materials with relatively high toughness, high abrasion resistance, and high and low speeds. It includes kitchen knives, chisels, files, and hand plane blades.

Figure 3: Close-up of a metallic workpiece clamped in a rotating machine chuck with steel twist drill bits

On the other hand, high-speed drill bits are useful in steel, metal, and drilling of other hard materials.

In contrast to cold work steel, high-speed steel offers 3-4 higher cutting speeds. It makes it suitable for high temperatures. It undergoes heat treatment and steel tempering at above 1,200 °C before cooling.

Manufacturers add cobalt coating to HSS to improve its strength, but it still doesn’t compare to the original cobalt drill bits.

HSS Pros

- It’s suitable for work at over 600°C

- It has a high level of compactness and high breaking strength.

- It offers excellent grind during production.

- It functions optimally at high cutting speeds.

- It’s easy to maintain with a seamless sharpening of blunt tools.

- It’s easily affordable at a relatively low price.

HSS Cons

- Although more affordable, it wears faster than cobalt drill bits.

- It works less efficiently on specific materials with high hardness, such as stainless steel.

- Its finishes are of low quality in comparison to cobalt.

- Its edge frequently requires replacement, although it is sharper than cobalt.

- The frequent replacement ultimately reduces HSS durability in the long run.

3. What are Cobalt Drill Bits?

Cobalt drill bits are extensions of high-speed steel with an additional 5 – 8% cobalt element. It’s much harder than HSS and seamlessly drills into harder surfaces. These include red-hardened steel, stainless steel, and other sturdy materials. Cobalt drill possesses virtually all the characteristics of HSS but in excess. For instance, it’s more heat resistant, durable, and impacts stronger with a higher penetration ability.

Figure 4: Making a hole in a circular bar with a machine and drill bits

Application of Cobalt Drill Bits

Owing to its high impact strength, we highly recommend cobalt drill bits for hard steel and metal drilling. These include stainless steel and some cast iron. It is effective in materials that require a high temperature of up to 1,100 degrees Fahrenheit.

Cobalt Pros

- The 5-8% cobalt element in cobalt drill bits gives it additional strength and durability.

- It’s effective against hard metals, stainless steel, and cast irons, which gives it an advantage over high-speed steel.

- It offers more wear resistance and works optimally at higher temperatures than HSS.

- It requires a smaller flute that hardly snaps during use and produces a better effect than HSS drill bits.

Cobalt Pros

- It’s expensive as it costs much more than HSS

- It’s not suitable for multipurpose work like HSS drill bits.

- Generally, it offers less value for money in comparison to HSS.

4. HSS Vs. Cobalt Drill Bits

These are some of the differences between high-speed drill bits and cobalt drill bits:

• Application

HSS drill bits are ideal in relatively hard metals and wood, while cobalt is suitable for hardened metals, cast iron, and stainless steel.

• Brittleness

HSS drill bits are more elastic and, as such, do not break easily, while cobalt drill bits are more brittle and chip off quickly.

• Resistance to Heat

•HSS has less resistance to heat, while cobalt drill bits operate efficiently at extreme temperatures.

• Constituents

HSS contains steel and other elements such as chromium and vanadium, while cobalt drill bits have additional 5-8% cobalt apart from these elements.

• Durability

HSS is less durable, while cobalt lasts longer under proper maintenance.

• Versatility

HSS is more suitable for multipurpose use than cobalt drill bits, giving it a better value for money.

• Price

•HSS drill bits are generally more affordable, while cobalt is a bit high-end.

Figure 5: Hole saw resting on a surface after use

Which HSS and Cobalt should you use for your application?

By now, we believe you must have been able to determine the right drill bits to use between HSS and cobalt. The materials, application, and budget are some factors you need to consider before making a choice.

Here is a video on how to drill holes in stainless steel with HSS/Cobalt drill bit

Summary and General Suggestions

Irrespective of your decision, whether you’re going for high-speed steel or cobalt drill bits, you can always count on NC Cuttings Tools. We offer high-quality cutti

ng and grinding tools, including segment, saw blade, music slot tile saw blade, and diamond wire saw, amongst others.

For over 20 years, we have built a reputation as a cutting tools manufacturer with expertise in designing customized tools in bulk for diamond tools suppliers and distributors. You can talk to us at your convenience, and we will gladly guide you through the selection process.