One of the most underestimated tools in a toolbox is the ring saw. It is a shock to me because, in all my experience researching expert cutting tools, the ring saws prove to be one of the most effective and versatile cutting tools. They are very handy and cut through almost any material.

Also, a lot of handypersons find picking a ring saw quite challenging. Well, if you fall into that group, I’ll reveal all the secret tips for picking the best ring saws to you in this write-up. Now let’s begin!

Table of Contents

What Is A Ring Saw?

A ring saw is a handheld cutting tool that is effective in cutting areas inaccessible or unreachable to bigger road saws. It is a variation of the band saw with a rigid band.

Unlike normal saw blades, ring saw blades are abrasive and not toothed. This abrasive coating allows them to be more stable while making precise cuts.

They are very strong and can cut through hard materials like stone, marble, glass, and granite, and they are very popular in the concrete sawing industry. Construction workers commonly use ring saws to create openings and insert windows and door frames amidst other amazing uses.

(Concrete sawing)

Benefits Of A Ring Saw

Where are you wondering about the other amazing uses? Welcome to this section! Here are some of the astounding benefits of a ring saw;

- Portable and practical: The ring saw is handheld and can fit into your space easily. It is not heavy and is easy to use.

- Versatile: One can easily detach the saw from its base, which makes it the best for any application. The cutting surface is big enough to work on large pieces, and you can also detach it from this space while working on small pieces.

- Powerful and safe to use: A ring saw, especially those with a diamond blade ring, can create cuts twice as deep as a standard saw.

- No vibration: The ring saw operates by spinning rather than vibrating. It is good news for those who dislike noise in their workspace.

Now that you’ve learned the basic ring saw facts, it’s time to discover the hidden secrets of picking the right saw.

Tips For Selecting A Ring Saw

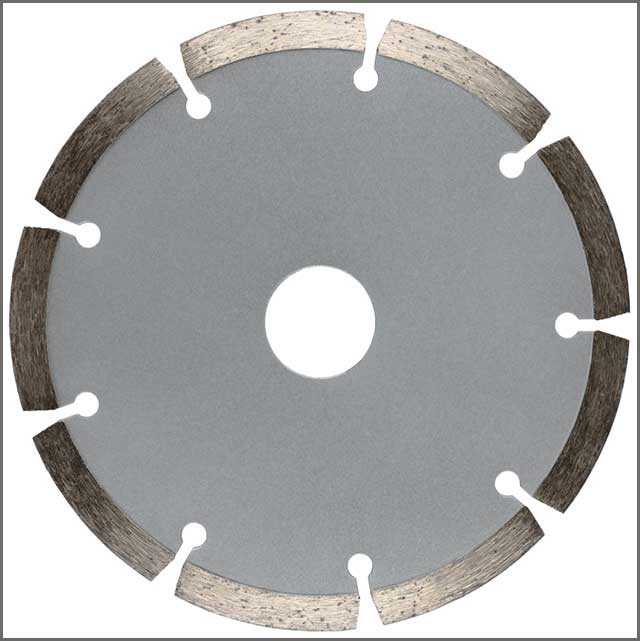

1. Know your blades

Blades are undoubtedly the most important part of a saw. A ring saw is only highly effective if the blade measures up to standard.

You do not pick a saw unless you understand the basic concepts that govern the blade and how the blade works. That’ll be a total waste.

Ring saws blade must have the following characteristics to produce maximum quality; hardness, toughness, and wear resistance.

No blade beats the diamond ring saw blades in emboldening all these properties. Diamond blades are the absolute best for ring saws.

Diamond is the hardest material, and this blade is made by having small diamonds fixed to its edges. It explains why they are so effective in cutting hard and abrasive materials. Picking diamond ring saw blades for your projects will be the best choice you’ll make for any operation.

They are not just really strong. They also help make the most precise and clean cuts with the ring saw.

Diamond blade rings are not just of good quality. They are also general-purpose blades. They can cut through hard materials and are suited for extensive and frequently repeated jobs.

It is also of utmost importance to pick a blade ring that matches your ring saws size. Do not pick a blade that exceeds the maximum blade diameter of your ring saw.

Video link on how to choose the right diamond blades

2. The most suitable material for a ring saw

The material you’re working on is huge in picking a ring saw. However, this doesn’t pose a challenge because ring saws are versatile.

Understanding your saw’s matrix will prevent wear and help it last longer. There’s a general rule: A diamond ring saws blade that cuts soft material should have a hard metal bond to prevent the diamonds from shedding away.

While a ring saws blade cutting hard material should have a soft bond.

Knowing every detail about the material you are cutting is also important. If you’re dealing with concrete, for example, you need to know the aggregate’s compressive strength, size, and hardness.

Your ring saw blade should match the material you use.

3. How to choose a ring saw with high durability

Ring saws are one of the strongest and most durable, aside from being highly versatile and able to cut through a wide variety of materials. It has a silent and easy operating mechanism that makes it long-lasting.

As said earlier, the saw operates by spinning rather than vibrating, which makes it less prone to wear.

The ring saws blade determines the durability and long-lasting nature of the saw. You have to pick a ring saw blade that syncs with your workload.

If you’re dealing with high cuts, check every blade detail. Are the cutting edges made of high-quality diamonds? If yes, the ring saw has a high chance of being strong.

The best way to be sure that you’re getting a premium, high-quality ring saw is by buying from a reliable brand. Different brands have varying designs, and some might not be authentic.

It is important to buy from the be to get a strong and reliable ring sawest. At NC cutting tools, we offer high-quality ring saws. Custom-made just for you.

(Diamond saw blades)

4. Select a ring saw with the highest cost performance

Cost per performance is one of the critical points to consider before buying a ring saw. How much are you willing to pay? OR How high standard is your project?

The basic determinant of the cost of a diamond ring saws blade is the amount of diamonds manufacturers weld into it. Diamonds are the most crucial raw material in manufacturing this tool.

The number of diamonds determines how hard and strong a blade is. A ring saw with a higher diamond content will boost productivity and last longer.

Before buying a diamond ring saws, you need to decide what’s higher in your production spectrum. The initial cost or the total sawing cost?

If you’re a beginner working on smaller operations, ring saws with a lower cost will be more economical. High-quality diamond ring saws are best suited for large projects and frequent use.

Although they’re more expensive initially, they pay on a cost-per-cut breakdown in the long run. Always choose ring saws with the highest cost performance. It’ll save you a lot of stress in trouble.

The good news is that you need not worry much about performance with NC cutting tools. We produce ring saws custom-made to your specifications. We offer the best value for your price.

(Different sizes of diamond discs)

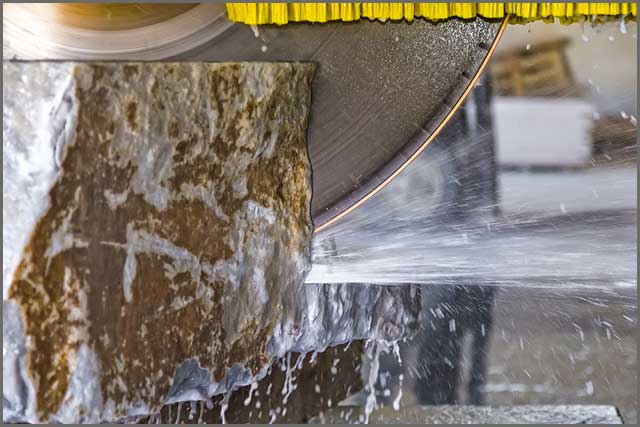

5. Wet or dry cutting

One of the most important factors to consider before choosing ring saws with diamond blade rings is the cutting method. Whether to use wet or dry cutting depends on the type of operation you’re carrying out.

Wet cutting is faster. You also do not have to worry about dust because the water cools the blade. Wet cutting is best for masonry, concrete sawing, and floor sawing.

These projects require the blade to cut hard material and would need cooling from time to time. The major disadvantage of this method is that it tends to leave your workplace wet and messy.

On the other hand, dry cutting is suitable for indoor jobs to keep the work area dry and clean. They are the best for handheld saws and make clean crisp cuts.

They require higher quality diamonds and use the air from the spinning blade to cool off. Although, this method won’t effectively cut very hard materials like granite. The decision you make depends on your preference and work requirements.

(Wet cutting method)

Final thought

The ring saws come in handy and will save you a lot of work headaches. Always follow the necessary safety precautions to prevent injury while cutting. Contact us at NCCutting tools for more information on buying specially customized ring saws.