Selecting a saw blade is difficult because there is a large selection in stores, along with a variety of knives with different numbers of teeth.

Not knowing how the number of teeth on a saw blade affect cutting is problematic because it could affect the quality of a job.

Understanding the relationship between the number of teeth and the cut speed helps folks know what type of cut they will get.

Table of Contents

- Section 1: We Should Know About the Amount of Sawtooth

- Section 2: Choosing a Saw Blade Based on the Cutting Experience

- Section 3: Saw Blade Speed Determines your Cutting Effect

- Section 4: How to Understand the Maximum RPM of the Saw Blade

- Section 5: For Those Interested in the Math, Here is the Speed Calculation Formula:

- Section 6: Tips for Selecting Saw Blades by Teeth Number

- Summary:

Section 1: We Should Know About the Amount of Sawtooth

The first step in effectively cutting wood for success is learning what you need to cut and the type of cut you are making. Whether a rip cut or a crosscut affects the saw blade choice. Material thickness is also an important consideration.

The first thing to think about is the thickness of the wood.

The simple rule is this: the thicker the forest, the fewer teeth. The reason is a saw blade with fewer teeth digs deeper into the wood during the cutting process. It pulls out more wood, allowing the saw to move through the forest faster.

Besides wood thickness, cut type matters as well.

Rip cuts go with the grain, and fewer teeth are on ideal blades for this cutting because they require a full gorge. Rip cutting is more relaxing, so using a knife with fewer teeth makes sense because the teeth on a saw blade for rip cutting are large. The gorges can capture and expel more wood, leading to faster-cutting speed.

A massive saw blade tooth is needed for thick wood and rips cutting because small teeth create more dust. This dust infiltrates the motor. The more dust accumulates in the engine, the worse the motor performs. Lower teeth cut wood for a more extended period. It means the motor runs more on the saw, creating greater heat with exposure to the small sawdust particulates.

Large teeth, though fewer in number on a circular saw blade, expel more wood while cutting, shortening the cut time. A shorter cut time means the motor has less chance of overheating for a long time without the engine.

Section 2: Choosing a Saw Blade Based on the Cutting Experience

Most saw blades contain between 40 to 80 teeth on the standard 10-inch blade. As detailed above, the fewer teeth on the blade, the faster the cut. At this point, it is incumbent to understand the advantages and disadvantages of having a certain amount of teeth on the blade.

The cutting experience is where blade selection comes into play. There are several reasons a beautiful, clean cut is needed. When using a miter for projects like crown molding, the rough cut provided by a saw blade with fewer teeth doesn’t look proper. Also, when smooth cuts are needed, the materials generally aren’t very thick or need a rip cut.

The other factor in cutting is the speed of the cut. Safety is paramount when using circular saws. Some folks can’t handle the fast pace of a 40-tooth blade cut. They can hurt themselves when feeding the wood. Table saws with spinning circular blades should have wood supplied using the guard.

For handheld circular saws, the key for folks using the saw is not moving the guard out of the way. It does not speed up the cut; it exposes the body to severe injury.

Before you choose a blade, please pay attention to what to cut. Fence posts, for example, should be cut with a blade with fewer teeth. Posts are generally 4×4; they’re very thick, and a blade with many teeth will wear out the motor.

Section 3: Saw Blade Speed Determines your Cutting Effect

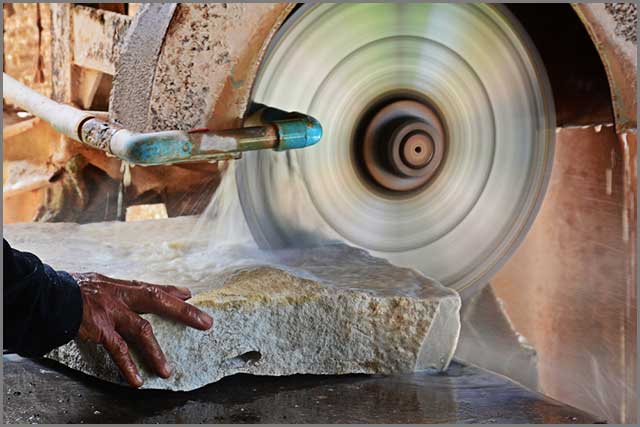

As previously established, fewer teeth on the blade result in a faster cut. The revolutions per minute (RPM) measures the cutting speed. RPM for circular and table saws varies from 3,000 RPM up to 50,000 RPM.

Saw blade speed has a relationship to teeth number. The small amount of teeth means the blade bites more deeply into the wood, resulting in a faster cut. The faster speed of the cut means a rougher cut.

Another consideration is the size of the blade. A saw blade with a 10-inch diameter has fewer revolutions than a blade with a 7.25-inch width.

The smaller two-blade shaves 5,300-5,800 RPM instead of the 10-inch diameter with 3,450 RPM. A handy table seeing the difference can be found here.

The accurate way to know how many teeth there are on a blade is by measuring the number of teeth per inch. Once you know that information, it’s easy to figure out how many teeth there are. The good news is there’s no need to work that hard. Because there are many teeth, the saw blade is usually introduced.

Another important measurement is linear feet per second (FPS). Similar to miles per hour, this tells cutters how far the blade would cover at a certain RPM. Therefore, blades rated at 130 FPS are not as fast as blades with 150 FPS — the smaller the teeth, the slower the blade, and the more excellent the cut.

Section 4: How to Understand the Maximum RPM of the Saw Blade

As stated above, RPM stands for revolutions per minute. A saw blade with 3,000 RPM will revolve 3,000 times in a minute. That may sound like a lot, but there are many nuances to the number itself. For example, just because a saw blade may have a maximum of 5,000 RPM doesn’t mean it’s safe to operate at that speed.

The maximum speed listed on a saw blade is how fast it can rotate. The optimum cutting speed is when the saw blade is cutting the fastest while remaining safe to use. Cutting at maximum RPM is extremely dangerous for several reasons.

A saw blade spinning at maximum RPM won’t bite the wood. Instead, the tooth will strike the wood. This strike can pop teeth off the blade and send them flying around. Even more dangerous, the blade can crack and break; a cracked saw blade flying around a workshop should be enough of a deterrent to turn the RPM to its maximum setting.

Section 5: For Those Interested in the Math, Here is the Speed Calculation Formula:

- (3.1416 X Diameter / 12) (RPM / 60) = FPS. For woodworking, if the number ends between 130 FPS and 170 FPS, that’s the proper speed. If there’s a number outside this range, it is either too fast or too slow, making the circular saw blade extremely dangerous.

- Here is an example of the formula in motion with a 6.5-inch diameter blade: (3.1416 X 6.5 / 12) (5,000 / 60) = FPS

- For the math to work, first, solve inside the parenthesis and do multiplication before division. Then multiply the parenthetical numbers to get FPS. The next step will look like this: (1.7017) (83) = 141.8 FPS. It is a safe speed to be operating the circular saw blade.

Section 6: Tips for Selecting Saw Blades by Teeth Number

- The most important thing to remember is that the cut’s quality depends on the number of teeth.

A fast, rough cut has a small number of teeth,h while a more delicate cut typically uses a saw blade with 60-90 teeth. Need to eliminate unwanted parts, and if a wound needs to be more beautiful, go with a higher tooth count.

- We need to know what to cut.

Plywood should have a higher tooth count because the timber is formed; tearing is a big problem for plywood. Using a higher tooth count for crosscutting is the best way to have a smooth cut and gets the wood nice and even for where it needs to go.

- If a saw blade works too hard while giving a slow cut speel.

Dull blades lead to engines overheating and compromising production. If the saw is getting hot, turn it off. Let it cool down. Make sure to clean out any sawdust because the engine will operate inefficiently if dust gets into the motor.

- Most saw blades for home use and contracting are between 40-80 teeth.

For simple crosscuts like framing or rip cuts. For plywood or miter cuts, go with a tooth count closer to 80. It will produce an excellent cut that’s aesthetically pleasing.

Summary:

There is more to wood cutting than just using the circular saw, and understanding the relationship between saw teeth, speed, and the type of cut can only help people stay safe. Using the right saw blade also increases the quality of the cut and reduces the amount of wasted material.

Cuts are efficient with the right blade, so take some time to evaluate the wood being cut and select a proper saw blade using the information above. You can go to our official website to learn more about https://www.nccuttingtools.com/