Do you know that cutting dates back to the earliest generation of man, but it only began to gain prominence in the 17th century? Nevertheless, technological advancement in saw blades has been immense, and choosing from varieties has become daunting.

Some blades are good for cutting wood but are not suitable for cutting metals. The suitability of a particular saw blade for a specific application depends on your level of understanding. This article will guide you and equip you with essential knowledge on saw blades and materials they can cut efficiently.

Table of Contents

- 1. The choice of suitable material diamond saw blade core portion

- 2. Diamond Blade Selection

- 3. Saw blades for hard and soft materials

- 4. Frequency of Saw Blade Operation

- 5. To distinguish the angle of the teeth

- 6. Wet or Dry Cutting

- 7. Teeth per inch of the blade (TPI)

- Conclusion:

(Figure 1 Set of Diamond Blades)

1. The choice of suitable material diamond saw blade core portion

Knowing the type of material you intend to cut, it is essential to understand the components that make up the diamond saw blade. Typically, Diamond blades consist of a steel core impregnated with diamonds and its segment. The focus is usually a round flat metal disc used to support the outer layers. The ring is attached to the heart using various advanced processes such as vacuum brazing, sintering, laser welding, and electroplating. The diamond and the metal bond make up the segment.

On a general note, Diamond grinds, but don’t cut! The metal bond is responsible for holding the diamond in one piece. The surface of the outermost diamond does the grinding as it rotates through the workpiece or material, producing fine powder of the grain.

The diamond used for this purpose is synthetic as against the natural type. Controllable characteristics of synthetic diamonds during manufacture are crystal shape, strength, and size. Essential factors to consider about diamonds are:

Amount of Diamond in the segment: As the percentage of the diamond increases, so does the power (horsepower) needed to drive the blade through the workpiece. This requirement implies that edges with high strength contain a lot of diamonds in their segment.

Quality of the diamond in the segment: This refers to the sharpness of the edge of the diamond. It contributes to the resistance it can pose to heat and a temperature rise.

Size of the diamond in the segment: The size of each diamond crystal determines the fineness of the chip particle. In practical application, beautiful diamond saw blades are useful in cutting sturdy materials like chert or quartz. In contrast, the coarse diamond best fits soft materials like soft red clay and asphalt.

(Figure 2 Concrete Diamond saw blade)

2. Diamond Blade Selection

It is essential to understand the diamond saw blade’s various components and the factors contributing to its performance. It is also vital that you know the basics behind the different types of saw blades available for various jobs:

i. Crosscut saw blade:

Crosscutting involves cutting across the grain at a slow speed. If you desire more excellent cuts on your material/workpiece, you should consider using a crosscut blade. It gives a smoother cut because it has more teeth and less space for waste chip removal.

ii. Metal cutting saw blade:

Just as the name implies, it is primarily for cutting metals of any type. It is a family of saw blades which consists of modules such as band saw, cold saw, etc. Protection against sparks and shards is another unique feature of Metal cutting saw blades.

iii. Diamond saw blade:

If you need to cut materials such as stone, concrete, coal balls, asphalt, bricks, and ceramics, then a diamond saw module is the right saw for the job. With diamond-encrusted around the edge of the circular blade, it can practically cut through any material.

iv. Table saw blade:

This is a relatively large woodwork cutting tool. Its circular saw blade is mounted on an arbor and driven by a motor. A table is expected to support the workpiece during operation to ensure high precision and accuracy. Benchtop, job-site, compact, hybrid table, contractor, and cabinet table saw blades are the numerous configurations of table saw blades in the market.

v. Reciprocating saw blade:

This is yet another fantastic saw blade that can cut through wood or metal. The tooth-per-inch (TPI) of the blade goes a long way to determining the material it can cut. Lower TPI blades are suitable for wood as the cut is usually fast, while higher TPI blades are ideal for metals as they produce smoother cuts but slower cutting rates.

vi. Tile saw:

There are two main types of tile saw blades: Dry tile saw blades and wet clay saw blades. A similar feature of both modules is that their edges are diamond coated. The damp module can help complete any stone-cutting task; under no condition should it be used without having water around.

The damp surface helps to cool down the knife and ensure durability. They cut pipes, fiberglass, and other stones. The dry leaf is limited in usage. It can run dry but is best suited for removing old tiles during refurbishment work.

vii. Rolling saw:

This is suitable for thin materials. The most exciting quality of this saw is that it doesn’t require a pilot hole to make accurate cuts.

(Figure 3 Set of circular metallic saw blades)

3. Saw blades for hard and soft materials

• Soft Materials

Non-abrasive soft materials such as cardboard, polystyrene, leather, carpet, and rubber must also be cut accurately. Unlike hard materials such as wood or metal, soft materials require special care when cut to avoid damaging the material. Worthy of mention are the saws below:

• Special Jigsaw blades :

Its sharp knife edge has a material composition of high-carbon steel. This saw can cut irregular or curved shapes due to its thin blade tracked throughout the cutout.

• Band Saw Blades:

Usually made of stainless steel suited for cutting meat. The teeth are beautiful with heat-treated tips.

• Hard Materials:

Woods, metals, stones, porcelain, concrete, asphalt, tiles, etc., can be classified as hard materials. Saw blades for cutting hard substances should be tough enough to withstand their hardness. You need to know these blades have distinctive characteristics. The saw blades that fall under this category are:

• Coping saw:

This is used interchangeably for both metal and wood. Interestingly, its unique feature is its removable blade and ability to cut a profile through a drilled hole. It is effortless to maneuver tight radiuses and curves as well.

• Miter Saw:

Perhaps you have been warned not to cut corners; this saw does precisely that. It is excellent for creating custom angles, especially in molding and trim jobs.

• Circular saw:

This is by far the most common of all saw blades. It comes in two generic types- the worm drive and the sidewinder. The worm drive can produce enough torque to cut through wet lumber and even concrete seamlessly. On the other hand, the sidewinder has its motor attached to its blade but produces less torque.

Other notable saw blades are table, tile, hole, abrasive, and radial-arm edges, which appear similar to the circular saw blade.

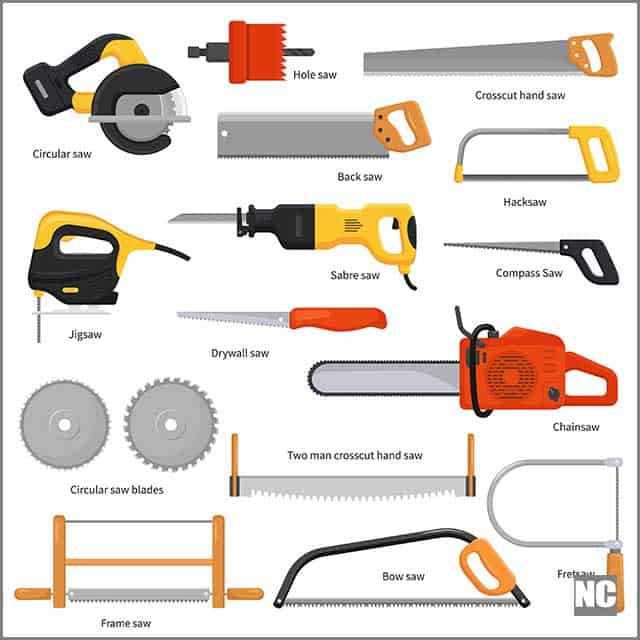

(Figure 4: Varieties of saw show jig and circular saw blades.)

4. Frequency of Saw Blade Operation

Depending on the nature of your workpiece/material, you might need to repeatedly feed the content to the cutting tool and vice versa. The thicker the content, the higher the feed frequency, provided you use the appropriate diamond blade for the task. It is best to intermittently feed the content to the saw blade with care and caution.

(Figure 5: Close-up of wood-cutting by a carpenter. )

5. To distinguish the angle of the teeth

Hook angle, as it is commonly known, is a measure of each tooth’s forward or backward lean. The hook angle determines how much the blade’s tip penetrates the workpiece during cutting. Orienting the saw blades at an angle is the best option.

Blades with a positive hook angle tend to self-feed the material being cut and can be dangerous if the operator is not cautious. Standard positive hook angle range from 5 to 15 degrees. Rip blades with a 20-degree positive hook angle are suitable for wood cutting. You can cut softer materials such as aluminum sheets or trim using knives with 18 to 22 degrees of positive hook angle.

In general, to prevent self-feeding, it is advisable to use blades with negative hook angles, especially for metal or hard material.

(Figure 6: Close-up picture of blades showing different hook angles)

6. Wet or Dry Cutting

A Wet Diamond Blade is a right choice for you whenever you need a deep cut with a reduced possibility of overheating due to excessive friction on the cutting surface(s). Because it is cooled using water, deeper cuts can be achieved at minimal heat generation and wear of the diamond around the blade tip. A dOn the other hand, a dry diamond blade should be employed when the material requires a shallow cut.

Damaged blades and safety hazards are some of the results of not using wet edges where appropriate.

(Figure 7: Diamond saw blade operating under wet conditions.)

7. Teeth per inch of the blade (TPI)

The circular blades are specified by thickness, diameter, and teeth per inch. The TPI helps to determine how smooth or beautiful a cut will be. While fine cuts result from a slower feed rate and higher TPI, rough cuts are synonymous with lesser TPI and fewer teeth. With fewer teeth comes deeper gullets between and a more aggressive chiseling action.

For instance, with a 10-inch saw, a 40-tooth blade is perfect for general purposes, and an 80-tooth blade for plywood. You should also note that thinner blades bear greater TPI.

Conclusion:

The tips enumerated above should help you make the best decision on the type of saw blade for your job. You should read more articles for more information. There are so many brands in the market that put preference on profit over quality.

Nccuttingtools is well-experienced with an array of cutting tools. They can always provide value-added before and after-sales services to derive maximum utility for your money. Feel free to contact us to resolve your cutting tool-related concerns anytime,