The table saw is a tool that is crucial to the cutting industry, particularly the lumber processing industry.

These components include the table saw blade, extension wings, miter gauge, and arbor assembly. All these components are crucial for the functioning of the device.

In this article, we will carefully navigate around the table saw blade. We will also focus on its applications and the different factors surrounding this blade’s use.

Table of Contents

- Section 1: What is a Table Saw Blade?

- Section 2: Type of Table Saw Blade.

- Section 3: How to change the table saw blade?

- Section 4: How to Sharpen the Saw Blade?

- Section 5: How High Should I Set My Sawblade?

- Section 6: Section 6: Differences Between the Portable Saw and Cabinet Saw

- Section 7: How Thick is the Sawblade?

- Section 8: What are the Best Saw Blades?

- INTERCO 10-Inch 80 Tooth ATB Woodworking Saw Blade:

- IRWIN 10-Inch Classic Series Miter Saw Blade:

- Freud 40-Tooth General Purpose 10″ General Saw Blade:

- Forrest WW10407100 10-Inch Kerf Saw Blades:

- Forrest WW10407125 10-Inch Kerf Circular Saw Blades:

- DEWALT 10-Inch table Saws Blade:

- OVERPEAK 10-Inch 90 Teeth Blade for Saw blade:

- HICO 40-Tooth 10-Inch Kerf Saw blade:

- Freud 80-Tooth Ultimate 10-Inch Blade:

- OVERPEAK 10 inches 80 Tooth Finish Saw Blade:

- Conclusion

Section 1: What is a Table Saw Blade?

The table saw blade is an essential part of a table saw. It is the cutting part of the table saw. Table saws blades consist of materials like stainless steel, tungsten, and sometimes even carbide.

You can use the table saw blade to cut materials ranging from lumber to sheet goods.

1.1 What Table Saw Blade use?

Different table saw blades exist, and they have unique features that make them suitable for different cutting purposes. You will need to clearly understand different factors before choosing the blade to use.

An essential factor to consider is the type of cut. Rip cuts and crosscuts are the two populous types of cutting available today. However, not all blades can make these cuts.

Some blades can make rip cuts, while others can make crosscuts. Besides, some blades can cut both styles. On some peculiar occasions, there are specialized blades you can use for specific materials or applications.

These make a solid case for having a good knowledge of saw blades and the type of cut you need.

1.2 Why Choose the Table Saw Blade?

Most users aim for the best blade to smooth and effectively cut woodworking and other cutting practices. They require a blade that satisfies both economic and performance criteria. The table saw blade is one such blade.

Some table saw blades come at a steep price but make up for their precision and durability. Another vital reason for owning a table saw blade is its wide cutting range. Table saw blades are applicable for cutting a vast amount of materials smoothly.

Section 2: Type of Table Saw Blade.

Having different table saw blades at arm’s length is also essential. These four main blade types are;

2.1 Ripping Blades:

The ripping blades are synonymous to rip cuts. As you know, a rip cut is a woodworking cutting type where you cut along the grain of the workpiece.

Most users refer to this cutting style as ‘Ripping.’ You should know that the ripping blades are fairly popular, and their unique teeth configuration makes them favorites for cutting stock.

Ripping Saw Blade

These blades often come with a 20-teeth configuration with wide gullets. This configuration makes them suitable for users intending to cut faster with lesser precision.

2.2 Crosscut Blades

Another popular table saw blade is the crosscut blade. The crosscut blades are popular for cutting across the grain. This blade’s key advantage is that it gives off lesser waste materials after cutting.

Crosscut Saw Blade

Cross-Cutting blades have teeth numbers in the 80 to 90 range. A 90-teeth configuration makes the crosscut blade cut slower but smoother than the ripping blade.

2.3 Combination Blades

The combination blades are diverse in their applications as they can rip-cut and crosscut. Their unique quality of carrying out both rip-cut and crosscut makes them more popular among table saw users.

Most people call them general cutting blades because of their peculiar features of rip-cutting and crosscutting.

Combination Saw Blade

Combination blades mostly come with a 40-50 teeth configuration, with medium-sized gullets. The teeth number and gullet size enable the combination blade to execute both cuts well.

2.4 Composite Blades

This blade type is popular for its specialized functionality of cutting materials other than lumber. They are effective for cutting plywood and other special materials.

Combination blades come in different types and materials. Each type possesses specific attributes that make it suitable for cutting select materials.

All of these blades have their functions and advantages. You can read about how to choose the right saw blade to know more.

Worker using a Composite Blade

Section 3: How to change the table saw blade?

3.1 Working Method of the Sawblade.

The table saw has three major parts, namely;

- Electric Motor

- Table saw blade

- Table

(Saw Blade)

The electric motor sits below the table surface and spins the blade in a clockwise or anticlockwise direction. This statement implies that the electric motor converts electric power from the source to rotation on the blade.

The table saw blade must be turning towards you at all times. This turn must be such that you are feeding in the opposite direction. You must feed the workpiece against the rotation direction to ensure effective cutting.

Most users carry out two types of cutting on the table saw: rip cuts and crosscuts. The rip cut, particularly, cuts along the grain of the workpiece.

This cut aims to reduce the workpiece length while maintaining the original width. In contrast, crosscuts are cuts across the grain. As a rule of thumb, this cut reduces the workpiece’s width and maintains its length.

All other operations on the table saw are deviations or different manipulations of these types of cuts. Users only have to manipulate the blade angles or height to achieve different outcomes of cuts.

3.2 How to use a Sawblade?

The table saw is a tool most woodworkers must own. Using the table saw is relatively easy. Below is a step-by-step guide on using the table saw;

1. Know your Sawblade

(Saw Blade)

Different parts in a table saw; knowing what these parts do will help use the table saw. Some of the key parts of the table saw include

- The tabletop is usually of about a 3’×3′ dimension

- Rip fence that serves as a guide

- Blade guards to protect your hands

- Miter gauge

- Push sticks

2. Adhere to Safety Precautions

(Personnel on Protective Gear)

Like most power tools, the table saw can also be very dangerous. This statement means that you must practice safety precautions when using the table saw. Some of these safety practices include

- Wearing protective goggles to prevent your eyes from chips and kickbacks

- As much as you can keep your hands from a moving blade. Even if you must touch a blade, put it OFF first.

- Adjust the fence well enough to prevent kickbacks.

- Use an outfeed table to cut long lumbers.

- Choose the right blade for your job.

3. Making Crosscuts

(Crosscutting)

– Disengage your table saw from the power source and fix your crosscut blades.

– Select any angle between 0-180 degrees on your miter gauge.

-Align your workpiece with the miter gauge

-Slowly feed your workpiece to the saw blade

-Collect your cut workpiece at the rear end of the table

4. Making Rip Cuts

-Disengage the saw plug from the power source and fix it in your ripping blade.

-Size up the cut width you need on the workpiece with your rip fence.

-Align your workpiece with your rip fence

-Feed your workpiece to your ripping blade slowly.

-Collect your cut piece at the rear end of the table

Watch how to rip-cut here.

3.3 How to Change Sawblade?

Please disconnect the power: As a general principle, when working with saw blades, ensure to disengage them from the power source. This tip is a basic safety precaution to prevent electrocution or the saw blade from coming on.

- Removing throat plate and blade guard:

The throat plate and blade guard are an accessory of the table saw blade. After disengaging the table saw from the power source, the next thing is to remove the throat plate and blade guard.

This process can sometimes be different for different blades due to manufacturing differences. You will need to refer to the manufacturing manual to navigate the removal.

- Adjusting Blade height:

As a rule of thumb, adjust the blade height to give you maximum view and grip on the blade to allow for easier removal.

- Loosen the nut on the arbor:

The next task is to remove the nut on the arbor. The arbor is the part of the table saw that holds the blade in place. You will need two wrenches for loose nuts on the arbor and the washer.

As a rule of thumb, you can use a wrench to steady the washer while turning the nut anticlockwise. After you lose the nut, you can use your hands to remove the washer and the nut.

- Remove The Blade and Replace with The New One:

Replace the old blade with a new one. Ensure that the blade’s configuration is properly set with the teeth facing you and feeding the workpiece.

- Replace The Washer and The Arbor Nut:

You will also have to hold the new blade in place with the washer and arbor nut. After this, you tighten the nut using the same two wrenches.

- Replace the throat plate and blade guard

- Install your new blade and use

Section 4: How to Sharpen the Saw Blade?

4.1 How to Sharpen the Saw Blades?

Saw blades are like any other machine tool that reduces effectiveness with time. Cutting becomes harder and more stressful when your table saw blade becomes dull. Obvious signs to watch out for in your blade for dullness;

-When there is higher resistance to the feed of the workpiece to the saw blade

-Lesser precision and rougher cuts.

-Chips start to form, increasing the chances of having kickbacks.

When you start noticing these changes in your blades, it is a sign that you have to sharpen your blade.

Below is a step-by-step guide on sharpening your blade;

- Safety precautions are a must if you ever intend to sharpen your blade. Below are the key precautions to observe before sharpening your blade.

- You must disengage the blade from the power source and wear Personal Protective Equipment (PPE).

- The next step after the precautions is removing the blade. Sharpening a blade in the saw can prove dangerous even though it’s blunt. You must ensure to loosen the arbor nut and washer to remove the blade from the saw.

- Secure the diamond blade in the table saw. Replace the saw blade with the diamond blade. Ensure that the diamond blade is not too tight and not too loose. As a rule of thumb, it should be just about right enough to hold the diamond blade in place.

- Align the teeth and mark each tooth as you sharpen each to ensure you miss none. You can also sharpen the teeth together if they’re all facing the same direction.

- Connect the saw to the power source and turn it ON. After this, you slowly bring the inner part of your blunt blade in contact with the diamond blade.

- Repeat this same process for all the marked teeth.

- Detach your diamond blade from the sure once you are sure that the blade is sharp. Ensure also to clean your diamond blade to prevent rust

- Reinstall your blade into the table saws and connect to the power source. Turn it ON, and feed the table saw with the material. Watch out for faster cutting, demanding less effort and a smoother cut.

4.2 How to Clean the Saw Blades?

- The first thing to do before cleaning your table saw blade is to disengage it from the power source. This tip is a basic safety precaution you must always consider for table saws.

- The next step is gently scrubbing your blade with a stiff wire brush for any stubborn dirt.

- Stir a laundry detergent in water for about 5 minutes. Submerge the blade in the detergent solution for about 10 minutes.

- Use a soft brass wire brush to remove all the dirt gradually. However, be careful around the edges as it could still cut your hands.

- Remove the blade from the detergent solution and ensure it dry well. Failure to dry the blade properly can lead to corrosion.

- Install your blade plug into the power supply and turn it ON to continue to use.

Section 5: How High Should I Set My Sawblade?

Recently, a debate has been going on to define the height to put your blade best properly. Below are three assertions of that intent:

5.1 The Safest Cutting Height

As a rule of thumb, the overall dependable guideline is that the teeth’ blade should be 1/8″ over the workpiece. You should know that the reason for this blade guideline is simple.

These contributors claim a lesser probability of fatalities during accidents with the blade at this height.

5.2 Manufacturer’s Recommended Height

Manufacturers propose that you are safe if you have 3-5 teeth (ripping) and 5-7 teeth (crosscuts) in the workpiece.

The suggestion by the blade manufacturers is very similar to that of the claim for a safe height. They both are trying to minimize the extent of fatality in the event of a blade accident.

5.3 Higher Heights

As for the claim of having the blade at higher heights, there are some advantages. This suggestion proves that blades at higher heights will perform more effectively.

Blades at higher heights put less strain on the table saw motor and lesser heat generation.

Another claim is that cutting is neater and better at higher blade heights. Higher blades are of higher precision and better finishing.

This assertion of blades surely places the table saw performance over fatalities in accidents.

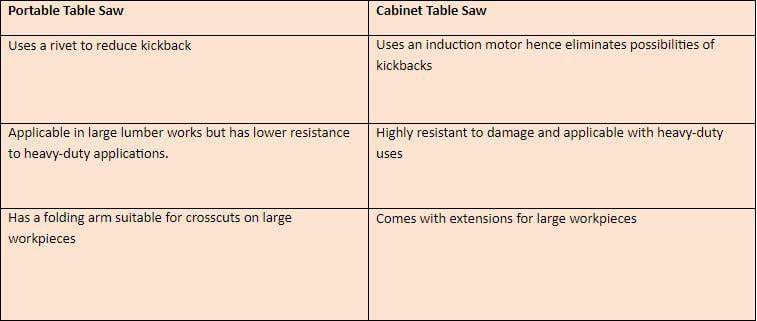

Section 6: Section 6: Differences Between the Portable Saw and Cabinet Saw

Advantages of Portable Table Saw and Cabinet Table Saws

- Both make woodworking easier

- They can both cut huge pieces of material.

Section 7: How Thick is the Sawblade?

The most popular blade size common to table saw blades is the 10-inch saw blade. Some manufacturers extend this blade size to 12 inches and above to suit particular applications.

Your blade’s size determines many things, from the blade’s compatibility to the type of finish.

You can measure your blade thickness from the kerf of your blade. There is mostly a thin kerf blade with 3/32 inches in kerf width.

In contrast, the full kerf is about 1/8 inch in kerf width, mostly applicable to costly materials.

Section 8: What are the Best Saw Blades?

INTERCO 10-Inch 80 Tooth ATB Woodworking Saw Blade:

The INTERCO 10-inch saw blade is the perfect definition of a general-purpose saw blade. It provides you with the multiplex ability to crosscut and rip cut. Beyond that, it can also give a sharp and precise cut.

IRWIN 10-Inch Classic Series Miter Saw Blade:

This IRWIN model is popular for its woodworking capability. Its 180 teeth configuration makes it the best option for smooth finishing. Maintaining this blade can be essential as it will prolong its sharp edges for smooth cuts.

Freud 40-Tooth General Purpose 10″ General Saw Blade:

The Freud general-purpose blade is a game-changer in woodworking. They have a particular flair for the way they cut wood without leaving any splinters.

Forrest WW10407100 10-Inch Kerf Saw Blades:

Particularly similar to the Forrest WW10407125 10-Inch Kerf Circular Saw Blade in design and applications. The only difference is that they are thicker. A huge upside to using this blade is the amount of waste material it reduces.

Forrest WW10407125 10-Inch Kerf Circular Saw Blades:

This Saw Blade is a typical 10-inch blade compatible with most table saws. They also come with a 40-teeth configuration suitable for precision cutting and finishing.

DEWALT 10-Inch table Saws Blade:

A typical 10-inch saw blade that gives a smoother and finer fiber finish. They sometimes come in packages that allow for different fine or smooth finishes.

OVERPEAK 10-Inch 90 Teeth Blade for Saw blade:

The unique finish with grey paint provides clear-cutting and reduces accidents.

HICO 40-Tooth 10-Inch Kerf Saw blade:

They are particularly popular for their low noise cuts, which create less noise pollution. This characteristic also makes it more comfortable to cut for a long.

Freud 80-Tooth Ultimate 10-Inch Blade:

The Freud 80-tooth blade comes with a protective coating that helps against rust. Their high teeth number also makes for a finer and smooth cut.

OVERPEAK 10 inches 80 Tooth Finish Saw Blade:

This blade comes with an 80-teeth configuration that makes it faster and sharper. They have teeth sharp enough to cut through materials without chipping.

Conclusion

Table saws as one of the essential power tools available today. This article highlights and discusses the key things you must know about table saws. By reading this article, you must have a great understanding of the table saw blade.

This article also highlights answers to the most common questions about table saw blades. You should look no further if you have more questions. NCCuttingtools has got you covered.

We have years-long experience and competent professionals to attend to all your needs. Contact us today!