Are you looking to try turbo blades for the first time? Have you already worked with these tools but want to ensure that you picked the most suitable units?

It is not easy to purchase a suitable turbo blade. You need to consider various features in the process. Here is an overview of the factors that can contribute to making a smart decision!

Table of Contents

- Chapter 1. Know What You Are Buying

- Chapter 2. Consider the Equipment Used

- Chapter 3.Think About the Material Suitability

- Chapter 4.The Importance of Cooling Capability

- Chapter 5. Pick the Desired Size

- Chapter 6. Consider the Noise Levels

- Chapter 7. Are You Planning on Dry or Wet Cutting?

- Final Thoughts

Chapter 1. Know What You Are Buying

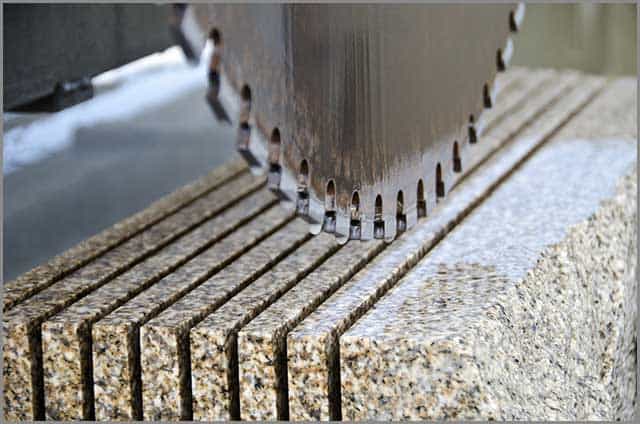

Caption: Circular saw used to cut granite

Before you consider the exact features of turbo blades that you need, get to know the tool a bit better. By understanding its basic characteristics, you will be sure about making the right choice.

The first thing to know about turbo blades is that they belong to diamond tools. Diamond is a specific material because it ensures the impressive longevity and sturdiness of the blade. Thanks to that, almost every blade is a wise investment in the long run.

You will find three main types of diamond blades – segmented, continuous, and turbo units. It is worth noting that continuous and turbo blades are rather similar. Their anatomy has similarities because they usually feature soft bonds. That makes them suitable for tough applications and ensures they do a reliable job cutting hard materials.

The difference is that a turbo blade has a serrated edge. The purpose of this specific design is to increase the speed of the blade. As the name suggests, turbo units aim at being extremely fast. That is why users who care about efficiency in their work also love using them. You won’t find many other tools effectively handling tough applications while maintaining admirable speed.

Chapter 2. Consider the Equipment Used

Caption: Cutting sandstone close up

It is crucial to note that diamond turbo blades are extremely versatile. You can use them in various tools, which is one of their main benefits. Have you ever tried using a tile saw with this blade and seeing its full potential?

Diamond blades are common in circular saws, and you can even use them in handheld grinders. Ultimately, the choice is up to you, but make sure the turbo blade is suitable for the equipment used. The tool you have in your workshop might not be able to fit blades of all sizes. Perhaps it is designed only for small blades, and a large unit wouldn’t fit right.

Make sure to check out the specifics of your tool. That will let you know about the dimensions of the turbo blades suitable for it. Based on that, it will be easy to search the market and find an appropriate solution.

Chapter 3.Think About the Material Suitability

Caption: A worker cutting stone

We already established that a diamond turbo blade features a soft bond, although you can also find units where the bond is a bit stronger than that. Either way, the bond isn’t heard because of the need to maintain suitability for strong materials.

That is what answers the materials you can cut with these blades. Turbo units are not designed to deal with wood, and there is no point in wasting them on plastic or other light materials. Their main purpose is to tackle strong and durable applications.

Here are some suggestions on the materials to cut with this tool:

• Stone

• Tile

• Masonry

• Granite

• Marble

The primary advantage of using turbo blades lies in cutting building materials. Thanks to these tools being fast, they can secure optimal results at an efficient rate.

The smoothness of the cut depends on many factors, but a smooth cut is something that turbo blades can deliver. You will need to maintain the tool optimally to ensure it delivers optimal performance. Additionally, it takes a bit of practice to use it properly. If you take care of those factors, you will be happy with the smooth cuts this blade can provide.

Chapter 4.The Importance of Cooling Capability

Caption: Cooling capability of turbo blades

The cooling capability of the turbo blades is their essential feature. That is because these tools are designed to work quickly. Since you operate fast, the chances are that you generate more heat in the process. That is why counteracting overheating issues becomes a primary priority.

Fortunately, the design of the turbo blade predicts admirable cooling capabilities. If you take a closer look at this tool, you will find that it comes with smaller segments than other diamond blades. That is critical because it ensures the unit cools down during the process. The segments feature a built-in interweaving matrix of diamonds.

The specific design ensures that the air goes through these segments. That is what secures the blade to cool down during the cutting process. Additionally, the blade might feature tiny holes throughout the tool. It is trick manufacturers apply to take cooling to the next level. That is particularly important if the operator is inexperienced and can’t foresee that they will have overheating problems.

The admirable cooling properties reduce the odds of excessive heat ever occurring. It is not only more suitable for newbies, but it also ensures that you work faster while maintaining optimal cutting results.

Chapter 5. Pick the Desired Size

Caption: Choosing the right diamond turbo blade size

Here is the good news – you have turbo blades available in various sizes. That is why the crucial thing to consider is to pick the size suitable for your application. Think about the projects that you plan to perform in the future. Since diamond turbo rim blades often last for a long time, it is wise to consider them a long-term investment. That is why you need the most versatile option for potential applications you will work on in the coming period.

The general rule is that the size of turbo blades goes up to 12″ in diameter. While you can also find larger diameters than that, their versatility is not admirable. It is more common that you encounter blades of a smaller diameter. Furthermore, turbo-cutting tools are available as small as four inches. Thanks to their impressive speed, these blades can be helpful for both DIY enthusiasts and professionals. Remember that maintaining them well is crucial to promote the blades’ longevity and ensure they serve you well.

Chapter 6. Consider the Noise Levels

Caption: Ear protection importance

Some manufacturers add a laser-cut core to ensure that the noise is somewhat reduced. That includes using an epoxy material, which can reduce noise. Other companies prefer a sandwich core. That approach secures even better noise reduction.

However, please note that these are still powerful tools. That means you need to be ready so that they produce a certain level of noise. It is only natural and required to do a decent job. That is why you should consider using protective equipment, such as wearing specialized ear protection devices like earmuffs.

Chapter 7. Are You Planning on Dry or Wet Cutting?

Caption: Wet cutting closeup

Dry cutting is a process where you don’t use liquid to cool down the tool while cutting. On the other hand, wet cutting involves keeping the blade wet to prevent overheating. What is the best way of using turbo blades?

The good news is that these tools are suitable for cutting materials. If you recall, we mentioned that these units have impressive cooling properties. That is what makes them suitable for extremely high temperatures. You could say that diamond turbo blades have a cooling system that helps them work in conditions that would create extreme heat.

Yes, that means these blades are suitable for dry cutting. However, that doesn’t mean you can’t use turbo units for wet applications. Furthermore, it is encouraging to do so if you have the required space. Wet cutting applications require you to work outside because water and other liquids can be everywhere. However, wet cutting can speed up the process even further. It not only keeps the water cool but also helps deal with the residue.

Final Thoughts

The best advice we could give you on choosing a turbo blade is to consider your needs. Only by ensuring that the tool fits your requirements can you ensure that it will meet your expectations.

Sticking to reputable manufacturers capable of producing high-quality tools is also crucial. You can’t go wrong if you turn to NCCuttingTools. The company has over 20 years of experience making outstanding tools with durable and strong materials.

The manufacturer has modern equipment and gathers an experienced and skillful team. Thanks to years of experience, the employees know how to use the equipment to meet the client’s needs. They can also follow the customer’s requests to the smallest detail. Whether your order is simple or complicated, the company will ensure a quick turnaround and delivery.

Don’t hesitate to contact the company if you have an order ready. Even if you want to discuss the most suitable solution for your needs, NCCuttingTools is there to help. Send them a message to get suggestions on the best tool choice for your upcoming projects!