The table saw is classic. Famous for its simplicity and effectiveness, it is the perfect tool for cutting. Hitherto, the table saw has mostly been in use for cutting wood. Beyond its fame for cutting wood, most people question whether the table saw can cut metal. Luckily, our team has done an excellent job using the table saw for metal cutting. Here are the most useful tips you need to know about the process.

Table of Contents

- 1. Table Saw — Match Blade to Metal

- 2. Table Saw — Cutting Speed

- 3. Table Saw — Types of metal

- 4. Safety Tips for Working with Metal

- 5. Table Saw: Fence Adjustment

- 6. Table Saw: Setting the Blade Height

- 7. Table Saw: Cut-Off Block

- Summary

1. Table Saw — Match Blade to Metal

The type of blade you use is important in using the table saw to cut metal. Having the right blade enables you to cut through any metal. It means that if you are planning to do any form of cutting on the table saw, you must know the right blade to use.

Remember that there are two metal classes, Ferrous and Non-Ferrous metal. Ferrous metals are metals that contain iron in their structural composition.

Ferrous metal often mandates that you also have a ferrous metal cutting blade to ensure a proper cut. An example of ferrous metal is steel, which is popular for its ability to make reinforcement and other high-strength metals.

Non-ferrous metals, on the other hand, have a softer matrix making them easier to cut. So most ferrous metal cutting blades can cut to ferrous metal; examples of non-ferrous metals are copper and aluminum.

2. Table Saw — Cutting Speed

Cutting Speed or feed rate of the metal to the table saw is also an essential factor to consider. Know that the Speed of the table saw increases the faster the blade wears.

Beyond this, however, you can also change chip geometry, tool, and surface finish. Therefore, for the different metals you are cutting, you must know the recommended feed rate that will ensure longer service life for the table saw blade.

So, therefore, it is crucial to know your values for cutting speeds and feeds, as this will serve as a reference point to start cutting your metal. An excellent way to ensure you have the correct cutting speed is to try cutting on metal scrap.

In the end, a crucial factor when setting cutting Speed is the time it takes to dull a tool. You must always have an economic standpoint.

Sometimes it is better to run at faster speeds and have to replace your tools more, and sometimes the reverse is the case. So select your starting speed, and adjust it to the nature of the work.

3. Table Saw — Types of metal

Cutting metal on your table saw can sometimes be more complicated than you think. It is because you may have to cut different metals with varying strength characteristics.

Hence, you must have a good knowledge of the kind of metal you are cutting. Below are a few metals with a brief description of their material properties:

Steel

Steel is an iron derivative produced by adding carbon to pure iron. The reason for this hybridization is that iron is not resistant to corrosion. Carbon added to iron augments the corrosive property of iron.

This blends of iron and carbon up as far as possible is known as carbon steel. Adding carbon to the press makes the iron a lot more grounded, giving the compound improved qualities like hardness and resistance to heat. It also makes the steel harder to cut; hence you must have the right blade with the proper feed to cut.

Aluminum

Aluminum is famous for its unique properties of strength, lightweight, electrical conductivity, and capacity to frame amalgams with most metals.

Another thing worth noting is that aluminum is easier to cut compared to steel because of these properties.

Titanium

Titanium is a rare and costly metal. With superior engineering characteristics in strength and weight, Titanium is the engineer’s dream metal.

These rare, unusual properties make Titanium useful in advanced applications like in the aerospace industry. However, you must know that this material is difficult to cut due to its hardness.

If you ever have to cut this metal with a table saw, you must consider many things.

4. Safety Tips for Working with Metal

Cutting metal can be delightful and disastrous when you fail to consider certain safety factors. Let’s agree that if you are unskilled and want to start cutting metal with your table saw, you might get some cuts, which is perfectly normal.

However, these injuries can quickly escalate if you miss a step when cutting with your table saw. So here is a list of safety factors you must consider before cutting with your table saw:

i. Do not run your fingers through freshly cut metal.

ii. You must understand that metal cutting takes time and diligence. So you must never rush through cutting the metal and creating burrs along the cut line.

iii. If you are new to metal cutting, you should try to get protective gloves to prevent any minor and unnecessary cuts.

iv. Wearing goggles, too, can be helpful if you have a kickback flying back at you.

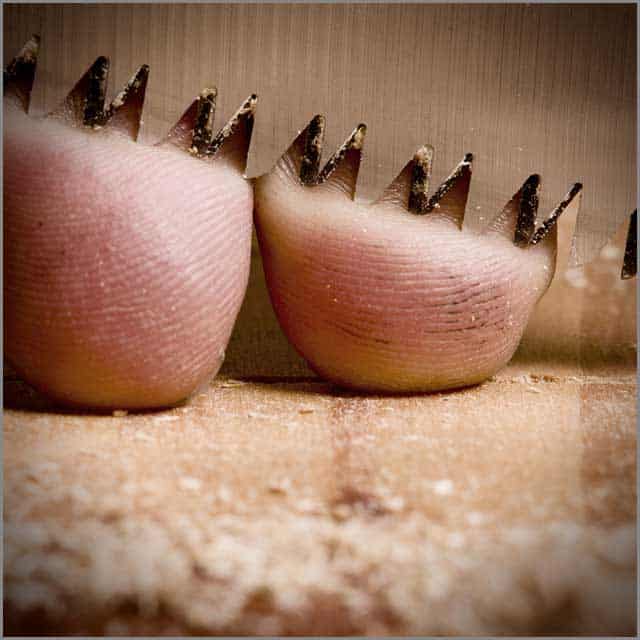

Figure 2: Saw Blade cutting hand

5. Table Saw: Fence Adjustment

Table saws, more often than not, come with a fence. This fence is the equipment that keeps your metal in line when you are feeding it through a table saw. The table fence adjustment ensures an accurate cut, as sometimes the metal can veer off course.

The first thing to do when cutting is to ensure that your fence is smooth to prevent your metal from catching. A proper fence adjustment will save you from second-guessing the accuracy of your cut.

So a fundamental way to have a secure and accurate cut is to have your fence safe and rigid.

Figure 3: Table Saw Fence

6. Table Saw: Setting the Blade Height

There are different opinions by different professionals on how blade height should place. The first thing is to set the blade slightly higher than the top of the metal.

With the blade height slightly higher than the metal, you can have cases of a kickback as the table saw teeth rips through the metal.

The kickbacks occur more often also because the table saw’s blade meets the metal horizontally. This method is particularly popular among professionals who don’t care about tear-outs on the metal.

Another popular opinion is how to have the blade above the metal. Unlike the previous opinion, this method will cause lesser tear-out on the bottom of the metal workpiece.

This method, however, is a bit dangerous because any slip from you will expose you to serious injuries from the blade.

Figure 4: Saw blade above metal

7. Table Saw: Cut-Off Block

As you will see, you will have more kickbacks as you attempt to cut metal directly against a rip fence. These kickbacks occur when the blade pinches your set board between your fence and the blade.

The blade gives off some particles that travel back right at you, and these kickbacks can sometimes be very dangerous.

Some manufacturers have put this problem into perspective and devised a solution.

This solution is the Cut-Off Block. It would be best if you clamped your block to the side of your fence reasonably from your blade. Do this, and you will stop all kickbacks.

Figure 5: Cut-off Blocks

Summary

The table saw is a cutting tool in wide use for different applications, and this is with good reason, as it is effective and economical.

More particularly in recent years, they have also been used to cut metals, completely different from the well-known modern wood. This article provides you with various tips on how to choose your table saw to cut metal.

So, as you continue to look out for a better understanding of how to use your table saw to cut metal, look no further. NCCuttingtools has got you covered.

Click here for a video with up-to-date information about your table saw and how to cut steel effectively.