You must have heard of the slitting saw if you’re into construction, manufacturing, or other related fields. Perhaps, you just bought it based on a recommendation and are wondering about the exact function of the tool. In this article, I will expound on the tool’s amazing multipurpose. Get your gear ready as I take you on an exhilarating knowledge ride!

Table of Contents

- 1. How To USE A Slitting Saw

- 2. Things you should be using the slitting saw for

- 3. Here are a few precautions to take while using a slitting saw;

- Final thoughts

Image of a slitting saw blade

1. How To USE A Slitting Saw

Here are some tips to follow for the effective use of the slitting saw;

• Check for wobble. Wobbling affects precision and is mostly a result of a crooked arbor. Resting surfaces with dirt or burrs also causes wobbling.

• Check the concentricity of the mandrel mounting and the saw base mounting. Make sure it is vertical so that you can easily cut when cutting.

• Make sure you’re using the right slitting saw size or diameter. A typical size is 3-4 inches in diameter. There are saws with larger or smaller diameters. The type of slitting saw blade you use should depend on the material you’re cutting.

• Be sure to use proper feeds and speeds. Slitting saws are very sensitive to heat. Use a proper feed and speed so the heat will not build up and ruin the tool.

• Check the arbor and saw hole size. The larger the sole hole size, the larger the arbor. Larger hole sizes are more desirable because they provide a more rigid setup which reduces deflection.

• Check for good chip evacuation. Slitting saw blades with larger teeth tend to be more chip-accommodating because of their increased concavity. Saws with small teeth have little room for chips. Therefore, if you’re going for an operation that requires more depth, use a slitting saw with larger teeth.

Here’s a video link on how to use a slitting saw

Now that you understand how a slitting saw works, it’s time to go into what you should use it for.

2. Things you should be using the slitting saw for

1. Cutting narrow slits or slots

The most popular use of a slitting saw is for cutting narrow slits or slots. It is capable of creating very thin slots with significant depth. As the name implies, it is designed to cut the tiniest slit and reach into metal parts that an ordinary saw wouldn’t dare reach.

It has similar roles to an end mill. But an end mill will give you rigidity and deflection problems if you cut too deep. A slitting saw’s cutting forces will be more advantageous, doing a faster and better job.

Image of a slitting saw blade on white background

2. Separating two pieces of materials

Metal cutting requires a very strong saw. A diamond-slitting saw can slit granite, fiber-reinforced glass, plastic, and a wide variety of other materials. You can use them for aggressive cutting. They’re also economical due to their low cost.

Although some home machinist thinks this tool is the next scariest thing to a fly cutter, you do not need to be afraid of the tool. If you have selected the right slitting saw blade and arbor. The tool will come in handy for you. All you need to do is follow the tips and instructions for the right usage.

With increased efficiency, a slitting saw can cut a material as thick as a rod in half. Although it is important first to ensure that your saw blade size can cut through the material, do not select a slitting saw blade randomly, as this can mar your application. Thicker saws are less delicate and more stable. Startup with a saw that is 1/16″ thick and a 1/8″ thick saw and waits for special requirements to try out other sizes.

Before using a slitting saw to cut parts into two pieces, determine whether the pieces can stand individually. Then check to ensure the cut parts are not loose or flung out. Ensure you hold both parts securely.

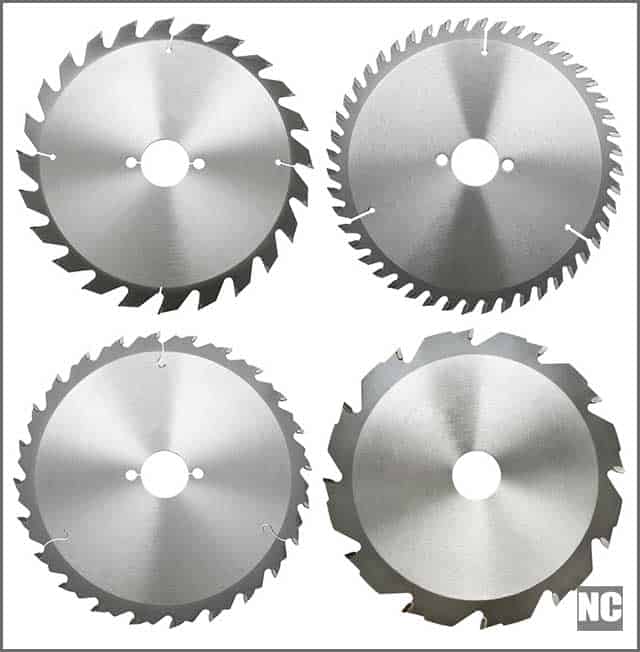

Different types of slitting saw blades

3. Undercutting operations

An undercut is a special type of recess that is not easily accessible using a straight tool. Milling refers to a part that is not visible if you’re viewing it from the spindle.

Some applications require that material be cut from a direction where the feature is not visible and hard to reach. These kinds of operations require specialized tools such as the splitting saw.

When you mount them correctly, slitting saws perform undercutting operations, removing the need to remount the workpiece completely. Creating an undercut on a part can be very tricky and time-consuming. It is important to work at a suitable angle for more efficient operation. The type of slitting saw blade you use would depend on the geometry and feature of the part you’re cutting. Deburring your parts by hand can be inefficient, but using a slitting saw will save you time and money.

During the undercutting process, ensure the blade runs true to the spindle’s axis. Check the slitting blade for runout by indicating and spinning it gently with your hand.

Slitting saw blade on the white background

4. Creating a relief slot

Another function of the slitting saw is to slot a workpiece and cut off slotted scrap from the workpiece. A slot provides more clearance for the chips to come out of the back without clogging the area. The relief angle on a machine tool is the tool’s angled edge nearest to the workpiece. Slots can take various shapes. They can be long or short, closed or open, straight or non-straight, deep or shallow, wide or narrow. Depending on the operation you’re carrying out.

The depth or shallowness of your slot depends on the feed per tooth of the slitting saw. Decrease the feed per tooth for a deeper slot and increase the feed per tooth for a shallower slot.

Adding a relief slot to an operation allows a part to move without compromising integrity by a wide length. At the same time, you can sometimes use an end mill to create a relief slot over many passes. A slitting saw is more effective because it can create the slot with just one or two passes. The slitting saws are designed to quickly create any slot without compromising the tool.

Saw blade with a defined tooth for smooth cutting

5. Marking graduations on a control knob

Graduation is a mark that indicates points on a visual scale. Slitting saws create standard and custom markings on a control knob. They make very small cuts and are highly effective in marking graduations without damaging the control knob.

There are indexable slitting saws with a carbide that you can use for this operation if your application permits. The plus side is that they are more economical in the long run.

Control knob with marked graduations

6. Making a thin disc of small diameters

There’s no tool more effective for cutting thin discs with small diameters than the slitting saw. The tool helps you cut out difficult parts to hold with the hand and is challenging to reach. It is also really fast and saves you a whole day of stress.

When cutting thin discs, use a standard tooth-slitting saw. They tend to be thinner than the coarse ones and have more teeth, giving a better finish.

Image of a thin metal disc with a small diameter

3. Here are a few precautions to take while using a slitting saw;

- •Keep your machine well-oiled.

- Sure, you’re cutting in the same direction.

- Cut at a reasonable speed to avoid blunting.

- Properly set up your machine to avoid manual injury.

- Use coolants to prevent overheating.

- Keep your hands away from the slitting saw blade to avoid physical injury.

- Keep your tool clean always.

Final thoughts

Slitting saws are very beneficial and are a valuable, high-end addition to your workshop. There are various processes and operations to perform with slitting saws. They are a great tool to have and help you get the job done quickly and effectively.

So far, you have learned a lot about the tool. You can get it out of the toolbox and start to work. Are you yet to get one and are on the lookout for high-quality slitting saws? Save your worries! Because we at NCCutting tools have covered you with our wide array of premium quality custom-made tools. Contact us and let us know what you need.