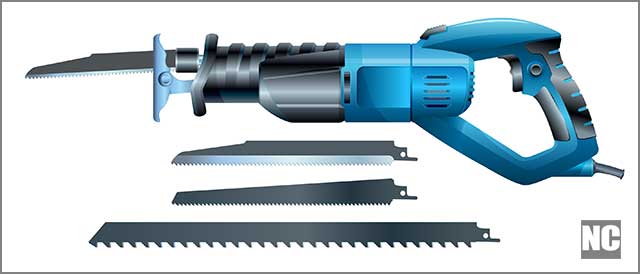

Reciprocating saws are highly powered saws that achieve their cutting action through a push-and-pull motion. Reciprocating saws are similar in design, often coming with a foot that rests on the surface you’re cutting. The point of the foot is to ensure the blade doesn’t move away from the cut while working.

It might be popular knowledge that the blade in this kind of saw differs in its material. But do you know the material can affect the other components, such as strength and speed? Suppose you’re an independent user, a material supplier, or a long-time professional. In that case, this article aims at helping you decide between two common materials used in reciprocating saws, steel, and carbide. We’ll do this by comparing them based on specific criteria.

Table of Contents

- 1. Reciprocal Saw Blades-Strength and Toughness

- 2. Reciprocal Saw Blades-Speed

- 3. Reciprocal Saw Blades-Flexibility

- 4. Heat and Impact resistance

- 5. Durability

- 6. Versatility

- Conclusion

1. Reciprocal Saw Blades-Strength and Toughness

In terms of strength and toughness, steel and carbide reciprocal saw blades differ widely. This property affects the kind of material they cut. On one end of the spectrum, carbide is one of the most hardened blades. It is much harder than steel and lasts much longer as well. This feature makes it ideal for going through equally as hard material. They can cut through high-density alloys like cast iron or nail-binding materials. This strength adds to the carbide’s resistance to wearing out and needing to replace the blade.

On the other hand, all that strength won’t be of much use when working with wood. Carbide tends to cut through wood slower when compared to steel. Steel is not as hard as carbide; therefore, using it on certain metals would quickly destroy its blade. High Carbon Steel is even considered one of the softest blade materials. Although High-Speed Steel is slightly stronger, at best, it cuts through non-ferrous metal like Aluminum. But steel is an excellent choice for cutting through soft materials like wood and plastic.

( Vector image of reciprocating saw blades)

2. Reciprocal Saw Blades-Speed

Regarding reciprocal saw blades, the fewer the tooth count, the faster it’ll be. However, this doesn’t displace the function of a property of the material in terms of speed. Very few blades can match up with bi-metal in terms of speed. But carbide does well enough in this department to be considered for speed amongst reciprocal saws. Carbide blades easily cut through materials faster than steel does. It exhibits a high resistance to vibration and impact, which allows it to stay sharper for longer and cut through metals faster.

In other words, speed also means it possesses more of an occupational hazard. Therefore, operating with great caution when using it is essential. Its speed makes it a sacrifice in the department of smooth edges. So, although carbide is excellent for getting the job done quickly, one has to bear rough edges. Steel is the way if you’re not time conscious and looking to finish your project with a more delicate finish. Steel blades offer less speed than their carbide counterpart. But cutting slower allows the edges of the material to be smoother.

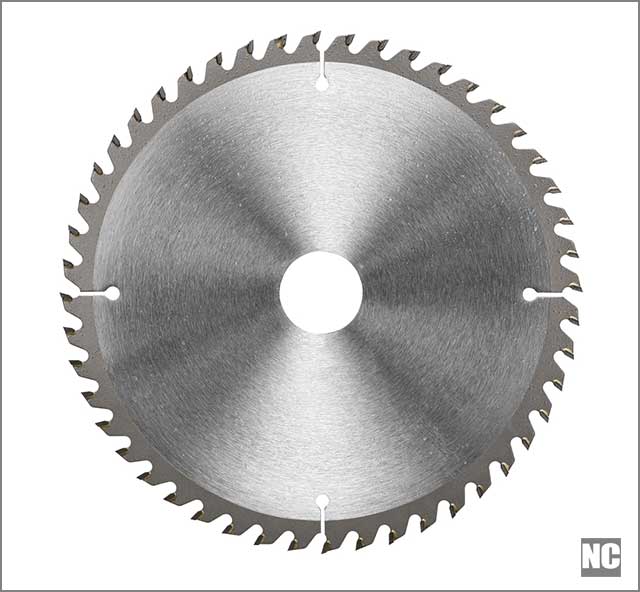

(Carbide saw blade)

3. Reciprocal Saw Blades-Flexibility

The flexibility of a metal determines the metal’s ability to resist bending without breaking. There is an obvious winner when comparing steel and carbide in this respect. Steel is considered one of the most flexible metals, allowing its numerous uses as a blade. Keep in mind that two kinds of steel blades are used in reciprocal saws. There’s High Carbon Steel, known as HCS, and High-Speed Steel, known as HSS.

HCS and HSS have similar but varying features, including flexibility. HCS is commonly referred to when steel receives praise for its flexibility. Its bendability makes it essential for cutting particular materials because it allows bending. HSS, on the other hand, is less flexible and thus more prone to breaking. However, carbide ranks lower when comparing carbide to both HSS and HCS in its ability to bend. It is harder than both steel types of metals and thus more resistant to warping during cutting. The length of a blade can also affect its flexibility.

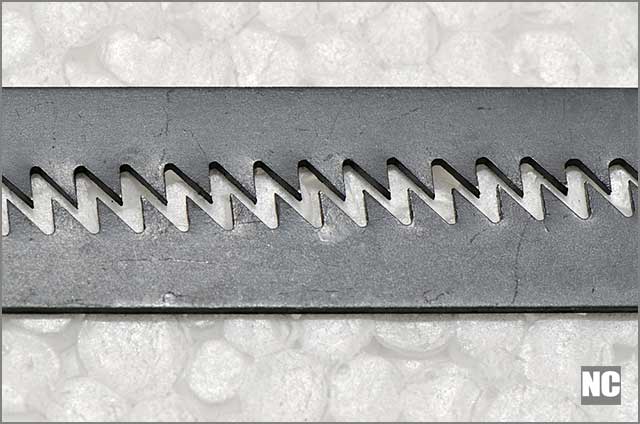

(Steel saw blade)

4. Heat and Impact resistance

As mentioned earlier, reciprocal saw blades made of steel may be of two types. High Carbon Steel(HCS)and High-Speed Steel(HSS) are two classes. They share similar properties, but like in their flexibility, they have other differences. Among these differences include their resistance to heat and impact.

A metal’s ability to tolerate heat and impact is highly correlated with its strength. That means more durable materials can withstand pressure, temperature, and impact better than blades made from lighter materials. As a result, HSS is more heat resistant than HCS. In turn, carbide is more resistant to heat and impact than HCS and HSS.

How does this affect their performance, you might ask? CCarbide’s added strength and resistance mean it can go through heavy metals seamlessly. In contrast, steel with lower resistance to heat and impact works best when cutting through wood, plastic, and non-ferrous materials.

(Saw blade and heat resistance)

5. Durability

Several factors can influence the longevity of a reciprocal saw blade. Not all elements are exclusive to the make and material of the blade. Examples of these factors are; how often the edge is in use and the kind of stuff it cuts. How well the user preserves the blade and the manufacturer can also affect its lifespan. When it comes to the internal features of the blade, just as many factors determine its durability.

Carbide blades tend to last longer than steel blades. It is due to many properties of carbide that steel does not possess. Carbide is thicker and more durable; the significant increase in its thickness makes it more durable.

The depth of a blade is inversely proportional to its flexibility. Thus, in addition to being more sustainable, carbide possesses less flexibility and higher resistance to bending. By being a more hardened and less flexible material, carbide is less prone to wear and tear. These features make carbide more excellent for long-term use.

It is also important to know that strengths such as thickness, which make it more durable, also make it more expensive. Steel, less sustainable due to its lightness and high flexibility, is cheaper. However, steel’s flexibility makes it useful on several materials. Its light natures limit its use of certain elements based on strength. Thus, it can easily break when used on harder metals.

(Two reciprocal saw blades)

6. Versatility

Steel and carbide vary significantly in their unique features. We’ve seen how these features can effortlessly intertwine and affect other functions. Such as how the lightness of steel makes it more flexible and easily bendable. We’ve also seen how the hardness and toughness of carbide make it more durable and resistant to heat. Consider the fact that these properties all have their pros and cons. Ensure you account for these while working on any job or project.

When dealing with hard and dense materials, carbide shows better resilience due to its strength and impact resistance. This strength, however, can be a drag when working on wood. Jobs that require a blade to be more flexible, however, benefit more from a steel blade. In addition, projects requiring a neater finish also benefit from a steel blade. In terms of durability, carbide outshines steel, which makes it better for ongoing projects. Steel, however, is more economical, so it might be a better investment for small and sparse projects.

Conclusion

Finally, steel and carbide are familiar and excellent materials for reciprocal blades. Now that you know how to choose between carbide and steel effectively. You should also keep in mind that it’s just as essential to get these blades from the right source. Your projects are likely to suffer, and you’re not going to get the best from blades of poor quality. Luckily there are just a handful of such places to get the right blades and other related tools. To start a home project or deliver cutting materials, you should consider NC Cutting Tools. We’re your first and best choice for high-performing and premium-quality tools.