Cutting Stainless steel ranks as a popular raw material in the manufacturing sector. The reason for the mass adoption of this material is its material strength, durability, and corrosion resistance. However, these same features make the stainless steel very difficult to cut.

When cutting stainless steel, you will need sufficient background knowledge of the type of tool you want to use to cut the steel.

This article looks to supply you with much-needed information on how to cut your stainless steel.

Table of Contents

- Section 1: About stainless steel

- Section 2: What tools do we need to cut stainless steel

- Section 3: How to cut stainless steel?

- Section 4: Watch out for overheating.

- Section 5: What precautions do we need to pay attention to?

- Summary:

A worker using a saw to cut

Section 1: About stainless steel

Stainless steel is a type of steel variant. So, it possesses good physical properties. Stainless steel consists principally of iron and carbon in a two-alloy system. Chromium and nickel make stainless steel diverse in properties, which makes them corrosion-resistant.

Corrosion in steel occurs because of the iron present in its composition. It is why most manufacturers include other additives to improve their mechanical properties. After adding chromium to steel, it forms chromium oxide upon exposure to air. Unlike ordinary steel, this oxide forms a defensive surface to keep air and dampness from causing rust.

There are several types of stainless steel, but the most prominent are as follows:

Austenitic stainless steel

Austenitic steel is the most popular and used stainless steel. The simple reason for this is its good corrosive properties and low heat conduction. Another reason for its adoption is its superior mechanical properties. Austenitic steel best suits housewares, modern funneling and vessels, development, and building veneers.

Ferritic stainless steel

Ferritic stainless steel is another popular steel variant with comparable properties to austenitic steel but with better corrosive and mechanical properties. Hence, it is more suited for making clothes washers and boilers.

Martensitic stainless steel

Martensitic stainless steel is an exceptionally hard steel variant. However, it isn’t as resistant to corrosion as other steel grades. It contains just about 10% chromium and has applications in aeronautics blade manufacturing.

Duplex stainless steel is more or less a combination of austenitic and ferritic steel. Hence, they are more solid and adaptable. Duplex steels are popular in making paper and other petrochemical materials.

Advantages of stainless steel

- It is corrosion-resistant.

- It is easy to fabricate and has good malleability.

- Stainless steel is strong and durable.

- It is cost-effective for different applications.

- It is aesthetically attractive.

- Stainless steel is environmentally friendly.

- It is recyclable.

Section 2: What tools do we need to cut stainless steel

Stainless steel has numerous applications, ranging from cars to jewelry. Reshaping stainless steel for different applications is only possible when you use different metal cutting tools, namely;

Angle Grinder

The angle grinder is a portable handheld tool famous for abrasive cutting. However, due to its high cutting force, operators find it very suitable for cutting stainless steel. This tool can also cut thin and thick stainless-steel plates or sheets.

Dremel

Another handheld tool is Dremel. Due to the design of the reinforced resin cutting wheel, it can cut stainless steel and aluminum. Hence, this property makes it possible to cut high-carbon steel.

Chop Saw

The chop saw is very similar to other handheld tools. However, it has a pneumatic feature. As a result, this pneumatic feature gives it an automated edge over its counterparts. They are popular for thin sheet cutting and can cut quickly and more accurately due to their design.

Circular Saw

The popular circular saw has vast cutting applications and is also suitable for cutting stainless steel. Its flexibility makes it suitable for making custom patterns on stainless steel.

Jigsaw

The Jigsaw is another power tool that cuts curves effectively on different material surfaces. However, It’s important to note that cutting steel always gives off high heat residue that can sometimes damage the steel. The Jigsaw comes in at this point to carry out longer cuts at high temperatures without risking losing your cutting tool.

Band Saw

The band saw is most suitable for doing cut-off works. Recent applications like cutting pipes and rail stocks are the most common you will find around. They are easy to use with their horizontal cutting application. Band saws can also cut stainless steel like the Jigsaw. However, the only difference is that it must be at a lower speed.

Plasma Cutter

The plasma cutter is a technological innovation that uses a concentrated energy beam to cut through materials. Over the years, the plasma cutter has expanded in metal cutting applications. The plasma cutter is best suited for thick stainless steel that other tools can’t cut through.

Section 3: How to cut stainless steel?

3.1 Preparing the workspace.

You’ll need to set up your workspace regardless of your chosen tool. A rigid and robust workbench will help to achieve stable cutting. If you use flammable tools, ensure that your combustible workspace materials are removed.

3.2 Measuring for the cut.

Use your standard measuring tape to get an exact estimation for the region you need to cut. Use markers to mark out points you want to miss. If you are missing a straight line, use a ruler or try a square to get an accurate cut.

3.3 Cutting the steel.

After measuring and marking the steel, the next thing is to choose the most suitable tool to cut the steel. You can have thin or thick steel plates or sheets requiring different cutting tools. Thin stainless sheets are most suitable to cut with tin snips. In contrast, thicker sheets will need power shears, circular saws, or plasma cutters.

3.3.1 Cut stainless steel with a saw

The circular saw is the go-to power tool for cutting steel having a great thickness. However, while using the circular saw, you will also need a metal cutting blade that can cut steel. Next is to turn on your saw and let it run for some time before you begin cutting. Subsequently, carefully lower the saw blade on your steel to cut.

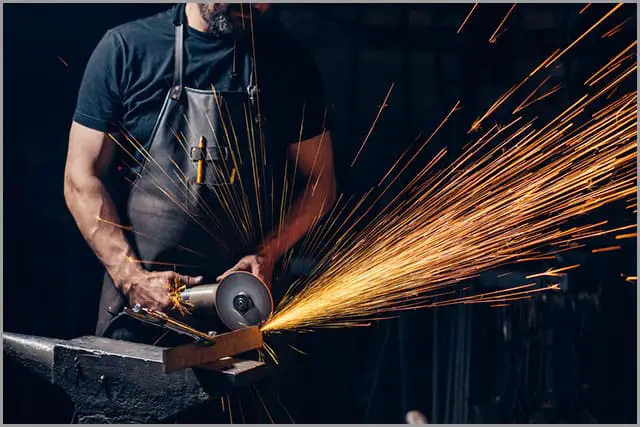

3.3.2 Cut stainless steel with a grinder

An angle grinder is a handheld tool you can also use to cut your stainless steel. You must also follow the same precautions and principles as you see in your manual to prevent accidents. It is also important to note that you must keep the grinder running for 5 minutes before cutting.

A worker using an angle grinder

3.3.3 Cut stainless steel with a tin snip

Similar to your workshop scissors, the thin snip is suited to cutting thin sheets. Use the tin snips slowly to create an accurate cut and to protect your hands from being cut.

3.3.4 Cut stainless steel with power shears

A power shear is a handy tool as they allow you to determine the cut’s type and way. Its major difference from the tin snip is its motor for automated controls. Again, this is a tool that will cut not so smoothly. As such, it mostly operates at low speed to get more accurate cuts. It’s best suited to cutting thin steel sheets.

Power shears

3.3.5 Cut stainless steel with a plasma cutter

A plasma cutter is a powerful tool that utilizes compressed air to make cuts in materials. It is most suitable for cutting thick stainless steel instead of thinner steel sheets. Therefore, to cut with your plasma cutter, connect it to your pressured cylinder and turn on the switch. You must set the current for your plasma cutter to about 25 or 20 gauge.

Next, turn in your cutter and move the torch along or across the stainless steel you want to cut. You will get the best result by moving slowly and in a very stable manner.

Cutting stainless steel

3.4 Clean up the edge.

It’s normal to have rough edges after cutting your stainless steel. To that effect, you have to create extra time to give your workpiece extra finishing. Use a hand file or a deburring tool to tidy up all edges to give your work a more professional look.

Section 4: Watch out for overheating.

Using stainless steel to make another item or structure has a lot of advantages. The advantages include high strength, flexibility, and toughness. One of the main advantages of stainless steel is its capacity to withstand heat and harsh thermal conditions. Nevertheless, cutting steel can heat up to alter the material’s properties.

Overheating may adversely affect the hardness and strength of steel. It is because overheating changes the microstructure of the steel. These adverse effects include prompting property harm as well as damage to the climate and injury.

Section 5: What precautions do we need to pay attention to?

All workplaces must be safe for cutting operations. This is because an accident can cause a serious mishap when you work with cutting tools. As a result, you need to make cutting operations safer.

Here are a few hints on the best way to make your workplace safe:

5.1 Tips on how to make your work environment safe

- Keep your workspace tidy for easy mobility.

- Light up your work area properly

- Place your power cables properly to avoid tripping over them.

- Proper ventilation

- You must remove all flammable materials from your workspace.

- Remove any jewelry, bracelet, or scarves.

5.2 Tips on how to protect yourself.

- Use goggles for Eye Protection

- Wear gloves. Hand Protection

- Wear industry boots for Foot Protection.

Summary:

Stainless steel is one of the most in-demand raw materials in manufacturing today. It is mostly down to its material structure and properties. However, cutting stainless steel can prove tricky if you lack the necessary knowledge about what to do. This article makes a concise step-by-step approach to how to cut stainless steel.

Therefore, look no further as you continue looking for helpful tips to find power tools that can cut stainless steel better. NCCuttingtools has got you covered.