Whether you’re a painter, or carpenter, or love a little DIY, it’s vital that you start a project with a very coarse type of sandpaper grit and gradually get smoother.

The problem is that sandpaper grit ratings can sometimes be hard to interpret and understand. For this reason, many people ignore it, resulting in their work appearing rushed, unfinished, or low quality.

This article will explain what sandpaper grit is and how you can use it to improve your wood or metal projects.

Table of Contents

What is Sandpaper Grit?

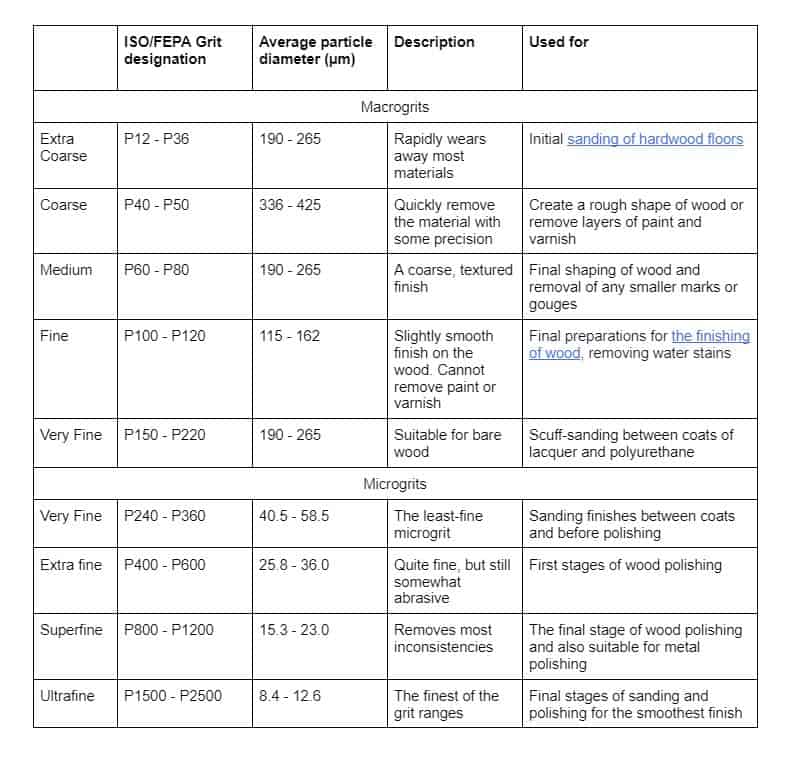

Grit is a measure of sandpaper’s coarseness. In other words, it tells you how quickly it will wear away the surface you’re using it on. A lower grit means the abrasive particles on the paper are more extensive and will wear down wood or metal faster. Higher ratings work much slower but produce a smooth and polished surface.

Polished wood uses the most acceptable grit ranges

Usually, professional wood or metal workers will begin the sanding process with a high grit to remove deep gouges and indentations. Then, they’ll gradually work through progressively higher nerves to create a polished finish on the wood or metal surface.

Sandpaper Grit Ranges

Sandpaper Materials

Natural Abrasive Materials

- Garnet – Wears quickly, providing a progressively more refined finish, and is a common choice for hand sanding.

- Emery – Has a cloth backing and is coarser, making it a great choice for metal surfaces.

Garnet sandpaper material

Man-Made Abrasive Materials

- Aluminum Oxide – As it brakes down, new edges are exposed. It keeps the paper sharp and means it lasts longer.

- Silicon Carbide – Made with a waterproof backing and is highly efficient. It’s great for wet sanding, but it does wear down quickly.

- Zirconia Alumina – An alloy that slowly breaks down to keep the surface sharp. It’s very long-lasting.

- Ceramic alumina – Extremely hard and durable, perfect for power sanding. This material lasts 6 times longer than others.

Aluminum oxide sandpaper material

Common Sandpaper Tools

- Manual hand sander – A padded base to clamp sandpaper onto, with a handle to provide extra leverage.

- Sanding sponge – Flexible, spongey material helps provide better performance under pressure.

- Vibrating palm sander – An electric sander that can hold in one hand to speed up the sanding process.

- Orbital sander – A power sander that moves in a circular motion.

- Random orbital sander – It also moves in circular patterns, but the entire sanding base simultaneously moves side to side and back and forth.

- Belt sander – An electric sander with lots of power due to spinning drums and fast-moving belts.

- Drum sander – Generates force through a cylinder containing a belt.

- Bench-mounted sanders – Can be mounted permanently to your workbench to reduce setup time.

- Floor sanders – Have large belts and drums for large-scale projects.

A power hand sander

Conclusion

This article has given a complete overview of sandpaper grit, materials, and tools. If you want further to expand your knowledge of sandpaper and cutting tools, please do not hesitate to contact us.