Stone-cutting blades are crucial tools when it comes to cutting ultra-hard stones. They are hardcore machinery that masons use to cut stones.

However, despite the usefulness of these tools, selecting the right stone-cutting blades often present numerous challenges. It is because stones come in different forms, shapes, and hardness. Choosing the wrong stone-cutting blades can reduce efficiency and and productivity and waste time. Thus, we will discuss seven tips masons and tool users can employ before selecting any stone-cutting blades.

Table of Contents

- 1. Determine the Hardness/softness of the Material

- 2. Understand the Qualities to Look out for in Stone Cutting Blades

- 3. Consider Your Budget

- 4. Identify the Merits and Demerits of Different Stone Cutting Blades

- 5. Determine the Job Duration

- 6. Size Matters

- Final Thoughts

Figure 1: A machine operator cutting a granite slab

1. Determine the Hardness/softness of the Material

It is very crucial to select the right stone-cutting blade. The materials tend to affect the cutting speed and life of the stone cutting blade. In the stone-cutting industry, most materials fall into four categories: hard, medium to hard, medium to soft, and soft. A harder material tends to soften the bond, eventually wearing it out. A worn bond will release the diamond before it glazes, which invariably makes the blade useless. Ensure you know the strength of the blade’s bond before introducing any material.

It is also imperative to have strong bonds when cutting soft materials as they will hold the stone segments in place to increase its lifespan. Some diamond saw blades for stone will also function well in this regard.

Most tool users often fall under the misconception that the hardest blade will cut everything; this belief is very wrong. The hard-bonded blade will not always cut hard materials effectively.

As a rule of thumb, you should get a blade for most materials. It simply means that you should focus on the most available materials and get a blade that suits them. If you have concrete as your primary material, you should get a stone-cutting blade that cuts through concrete easily.

2. Understand the Qualities to Look out for in Stone Cutting Blades

A handful of things to look out for when purchasing a quality stone-cutting blade. In this quality aspect, we will restrict our attention to three major parts of a stone cutting blade – the bond, the blade’s teeth, and the vibration/sound.

• The bond

The bond determines the materials that the blade will cut. If you intend to cut hard materials, you should go for stone-cutting blades with softer bonds and vice-versa. It would be best if you also understood that most stone-cutting blades grind rather than cut, which indirectly determines the wear rate of the blade.

For instance, cutting a hard material with a soft-bonded blade will expose the materials to more diamonds; this allows for a neat cut but will also wear down the blade quickly. Softer bonds are more durable as you can use them for universal blades. Using a soft-bonded stone cutting blade to cut or grindstone materials are possible; however, you are likely to dull the blade faster. A harder bond will be of immense benefit as it allows for durability. Cutting a hard material with a hard-bonded stone cutting blade is problematic.

Figure 2: A metal bond

• The blade’s teeth

In every stone-cutting blade, the teeth are what grind the materials. Another name for the teeth is ‘rim”. It is one crucial aspect you should pay attention to as it determines the finishing of your materials. Most stone cutting blades come with three significant types of rim: segmented, continuous, turbo rim. Each of these rims has its functions. We’ll look into them briefly.

Figure 3: Diamond disk rims

Segmented rim – This is best for wet and dry cutting. The rim segments help cool the blade down and blow out the dust, allowing for a quicker cut. A segmented rim also makes the cut rough. On the good side, segmented rims work well with medium to hard metal matrix bonds, which makes it the best bet for construction materials.

Continuous rim – this rim has smooth edges and cuts through hard and abrasive materials. This rim is sure to give you a smooth cut. However, if speed is one of your priorities, you should reconsider your options as it allows for slow cutting. This rim type is perfect for cutting stone slabs and tiles.

Turbo Rim – this is the best rim as you can use it universally on various materials. You can use this rim for wet and dry cuttings, plus it allows for quick cuttings. Stone cutting blades with this type of rim come with soft to medium bonds with serrated edges. These serrated edges make for fast and smooth cutting.

• Take note of the vibration/sound level

For safety reasons, this should also be a consideration when selecting the right stone-cutting blade. Some blades operate silently; others are semi-silent, while others will ring your ears with piercing sounds. If you have to use a diamond saw blade with piercing sounds, you should consider buying earmuffs.

Note that most conventional stone cutting blades have a very high-pitched whine, which can invariably ruin the serenity of the Jobsite. It can also hurt the ears of the handyperson making use of it. In this regard, it’s become imperative to go for stone-cutting blades incorporating silent technology to douse this noise feature.

How is a video to show the typical sound level of an average cutting stone blade while working on concrete?

3. Consider Your Budget

It would be best if you were quite tactical here as you don’t want to shoot yourself in the leg. Stone cutting blades come in numerous varieties as well as prices. In this regard, you should place price and quality side by side. Why? Getting a quality stone-cutting blade will keep you from incurring future expenses, as quality stone-cutting blades are long-lasting.

Also, if you’re looking to use it professionally, you should consider getting one that serves you well and longer. If you’re working on a small budget, you should consider getting one that can suit a variety of materials. Ideally, customized tools will help you to save more money, and that’s why you should consider speaking to any specialists from NC Cutting Tools to get a free estimate on your projects.

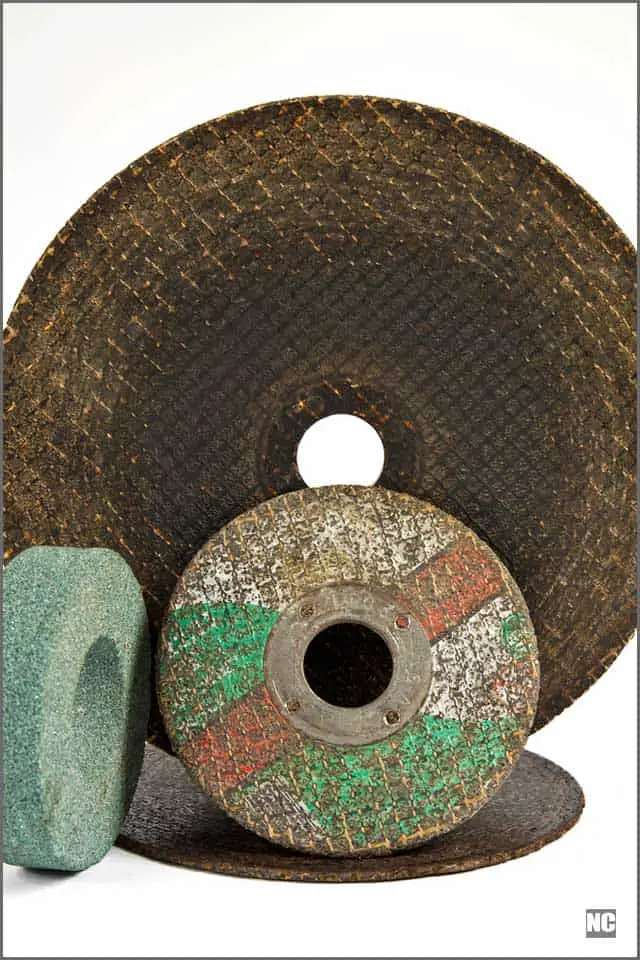

Figure 4: Different types of stone cutting blades

4. Identify the Merits and Demerits of Different Stone Cutting Blades

Like it or not, most stone-cutting blades, if not all, come with benefits and defects. In most cases, the defects and benefits depend on the materials. You should discern which stone-cutting blade will be of immense significance.

For instance, those with continuous rims will allow for a smooth finish. The lagging part of this equation is that you would have to put up with its slow nature, which most handypersons might deem a defect if speed is necessary. The goal is to choose stone blades with fewer defects and more benefits related to your needs.

5. Determine the Job Duration

How long is the job going to last? And if you have speed as one of your top priorities? These are factors you should consider when selecting a stone-cutting blade. The wear rate of most stone-cutting blades depends on the job duration and usage frequency. Most stone-cutting blades often come with usage durations. It would be best if you looked out for such features.

6. Size Matters

You may find it shocking to know that, most times, the same manufacturing company doesn’t make the equipment and the blades. It is more reason to be very careful when selecting stone cutting blades as you don’t want to buy the wrong size of blades for your equipment. Size matters in all ramifications here. It would be best if you also considered the sizes of the materials in question.

Figure 5: Different sizes of stone-cutting grinders

Frequently Asked Questions

We will be looking at some frequently asked questions most masons or handypersons tend to ask when they want to select the right stone-cutting blade

• What is the cost of stone-cutting blade?

Stone-cutting blades come in numerous varieties. These varieties are dependent on the materials as well as the sizes. Stone-cutting blades with advanced mechanisms are more expensive than their counterparts.

• On what materials can you use stone cutting blades?

You can use stone cutting blades to cut stone materials such as granites, concretes, bricks, asphalt, limestone, and the like.

• Which is better?

It all depends on the Material in question. Some stone-cutting blades will do well for specific materials, while you can use others to cut various materials. In some cases, most masons often prefer to go for multifunctional stone-cutting blades.

P.S. – If you have other questions, contact us here.

Final Thoughts

With the tips above, you should know why it is necessary to consider some factors before selecting a stone-cutting blade. The manufacturer also plays a significant role in determining the quality of the Material.

In this regard, NC Cutting Tools is a reliable company that manufactures durable blades that can outlast the job duration. These multifaceted stone-cutting blades will make your stone-cutting a seamless exercise. Plus, they are budget-friendly and affordable.

We are also in the business of manufacturing other diamond-cutting tools you can use on various construction materials. Are you looking to embark on any project? Schedule a meeting with any of our specialists, and let’s discuss the estimates.