Wet saw and dry saw, the art of cutting concrete, tiles, asphalt, and other similar materials, far beyond just using any saw blade. In order not to run into complications, you need to predetermine the most suitable approach even before commencing cutting.

Firstly, you need to know that the best saw for such a task is a diamond saw blade. Secondly, you must decide whether to wet cut vs. dry cut your workpiece. This article provides clear information to help you differentiate a wet-cut job from a dry-cut job.

Table of Contents

- 1. The Basics of Wet Cutting and Dry Cutting

- 2. Differences in Using Machines-Wet Saw and Dry Saw

- 3. Diamond Content of Wet Cut and Dry Cut

- 4. Wet Saw Usually Requires More Work Steps

- 5. The Precision of Wet and Dry Cutting

- 6. Service Life of Wet Saw and Dry Saw

- 7. Which Cutting Method Should You Choose

- Conclusion

1. The Basics of Wet Cutting and Dry Cutting

• Wet cutting-wet saw

Typically, a wet saw is a variant of a diamond blade saw owing to the compulsory and constant wetting of the blade teeth during cutting using water. Wet cutting is performed at high RPMs and is known to be precise, although it comes with a little messy due to the continuous presence of water. The high RPM of these saws translates into their preference and choice for many jobs among contractors. Bear in mind that wet saws can effortlessly take care of long and deep cuts

Since wet diamond saw blades were invented, issues surrounding cutting, such as overheating and the possibility of saw damage, were solved. Wet cutting is most applicable for materials that produce dust and chips while cutting, such as asphalt, concrete, tiles, and masonry.

A wet saw guarantees high efficiency in a hazard-free environment while achieving accurate cuts. In the case of wet saws, you need not worry about electrocution when using a wet saw. This has been well taken care of by designers- all cable has been properly insulated and covered to prevent any form of accident.

(Wet Cutting using a wet saw)

Generally, if you want to avoid dust, then wet cutting is your best bet.

• Dry cutting-Dry cutting saw

Unlike wet diamond blades, the secret to its exceptional performance lies in the design of the blade segment. This special design prevents overheating and thereby eliminates the need for water. If you desire to carry out decorative patterning on your concrete job, then a dry diamond blade saw is the best. Using this saw blade for smaller and quick jobs is more exceedingly comfortable. It is also capable of producing low RPM.

Dry cutting saw blades are also perfect for shallow intermittent cuts. For every 30-second cut, you take a break for 10 seconds to allow the blade cool. Another fact about the dry-cutting blade is that it is most suitable for straight cuts. The cuts produced are also very clean and fine. Amongst many contractors, opinions differ as regards dry-cutting saws. While some prefer using it for inside jobs, others believe it is more suited for outside jobs due to the dust it produces. Again, the dry saw is best suited when you have a shortage of water and little or no proximity to a water source.

Contrary to popular opinion, dry-cutting diamond saws can perform deep cuts, but you must take necessary precautionary measures and cut with attention.

(Dry Cutting using Diamond Blade saw)

2. Differences in Using Machines-Wet Saw and Dry Saw

Several characteristics distinguish a wet saw from a dry saw. Once you keep these characteristics in mind, you are one step further to becoming a pro in cutting. Such distinct features that differentiate a wet cut from a dry cut include the following:

• Wet cutting machines/saws

a.Wet cutting motors are waterproof to prevent damage or electrocution to the electric component of the wet saw.

b.They operate at the high speed needed to deliver a corresponding high horsepower.

c.Wet saws are environmentally friendly as they seldom produce dust.

d.Wet saws are mostly not handheld; they are mostly table-type saws.

e.Wet saw blades must continuously remain cool using water.

f.A wet saw must never be run dry without water to both surfaces of the material and blade segment.

g.You are most likely left with slurry to deal with if you are cutting concrete.

• Dry cutting machines/saws

a.There is no special need for making the motor waterproof.

b.In extreme cases, it can run wet. However, a wet saw can never be allowed to run dry.

c.It operates at low rpm to deliver intermittent clean cuts.

d.Its blade design makes it heat resistant by giving room for air-cooling.

e.They are mostly handheld and simple cutting tools.

f.It is suitable for both indoor and outdoor cutting.

g.When using a dry cutting machine, you need to have your PPE (Personal Protective Equipment) on, especially your eyeglasses and nose mask, because of the high level of dust produced.

(Dry cuts to raise dust)

3. Diamond Content of Wet Cut and Dry Cut

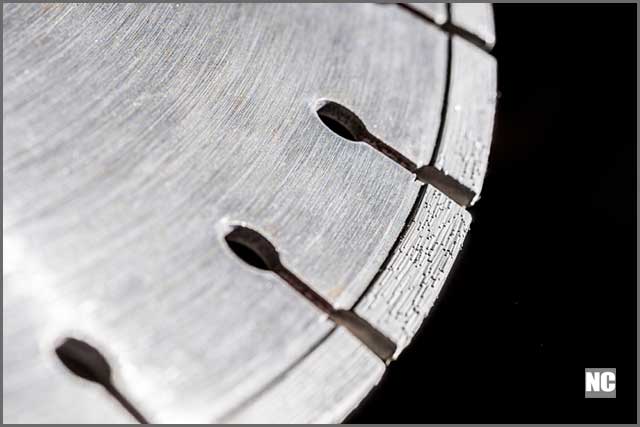

Synthetic diamond grits or crystals are machined and impregnated onto the surface of the circular saw using an advanced approach such as laser welding, sintering, or vacuum brazing.

Knowing that wet saws should handle aggressive, long, and deep cuts mean that the diamond grit bonding is soft to medium. Wet saws are stronger since they will undergo more cyclic stress during use. The continuous rim blade design is often used mostly for wet cutting because they provide a smooth and chip-free cut. The diamond bonding is around the segment of the blade.

However, for dry-cutting machines/ saws, a segmented diamond bonding or J-slot continuous rim blade fits the job. The diamond bonded is medium to hard, so heat dissipation is easy to achieve to prevent them from burning up.

( The Groove Cutting Diamond Saw Blade-wet saw)

4. Wet Saw Usually Requires More Work Steps

Furthermore, wet cutting involves a series of working steps and considerations before launching into use. Firstly, you need to pick an open space where water would not be a form of menace. Secondly, a dedicated proper water supply channel is available throughout the working cycle. Finally, an adequate disposal/evacuation system of slurry (a mixture of water and concrete, asphalt, or tile grain) must be implemented to ensure that the process remains environmentally friendly.

An essential provision for dry cutting is a dust extractor that collects the dust into a bag for later disposal.

(Man working with a wet saw)

5. The Precision of Wet and Dry Cutting

Wet diamond blades are such that the diamond bonding on the outer segment is continuous with no segmentation, which is responsible for the high accuracy a wet saw delivers; these saws come in a diameter of 4’’ to 14’’ in handheld and large circular saws options. Dry diamond blades are usually segmented at the blade tip to cater to air circulation around the blade- it is either slotted with a J-slot or a keyhole slot.

Depending on the project you have at hand, continuous-rim wet saws are best fit for ceramic tile, granite, and porcelain, while the slotted blades are good for asphalt, concrete, bricks, and blocks.

(Wet saw for U-groove)

6. Service Life of Wet Saw and Dry Saw

Wet cutting blades last longer in service, provided they are properly taken care of. The constant cooling of the blade limits the wearing off of the abrasive diamond bond.

On the contrary, dry-cutting blades tend not to last long as wet blades. Air-cooling is not always as efficient as water-cooling, removing heat when used, thereby leading to the faster wearing of the diamond grit on the outer segment.

Generally, a diamond blade service life ends when a considerable amount of diamond grit layers has worn off and become blunt.

(wet tile saw)

7. Which Cutting Method Should You Choose

Lastly, your cutting method choice should depend on the task’s environmental condition. Both blade types can do the job in some cases, but in others, it has to be specific. The table below classifies the blade with the kind of cut and working environment.

| Blade | Type of Cut | Environment |

| Dry Cut | Quick and Intermittent | Indoor and outdoor |

| Wet Cut | Long and Deep | Outdoor only |

Conclusion

Finally, we believe the differences elucidated above are key to helping you make your decision and sufficiently informing you of dry and wet cuts. For further help, you can read more articles.

At NCCuttingtools, our range of products and services cuts across all blades and cutting tools. We are always available to assist you in bringing expertise to your next project.