Can you cut plexiglass on a table saw? You can cut just about anything with a table saw in your home. Can you cut plexiglass on a table saw?

Yes, including plexiglass! A utility knife can get the job done if you don’t own it.

Cutting plexiglass on a table saw should not be frustrating anymore. By the end of this article, you will be able to cut plexiglass.

Table of Contents

- 1. What is plexiglass?

- 2.Types of Plexiglass

- 3. Strength of Plexiglass

- 4. Cutting Plexiglass Using a Table Saw

- 5. The Technique for Cutting

- 6. Alternative ways of cutting plexiglass

- 7. FAQs

- In Summary

1. What is plexiglass?

It is common to mistake plexiglass for ordinary glass. Often, manufacturers make plexiglasses out of plastics eventhough it might look like normal glass.

Therefore, it is a better alternative to glass because it does not break easily, it is stronger, cheaper, more durable, and is heat stable.

Plexiglass has a wide range of applications, including making light fixtures, screens, and windows, among other items that require clear screens.

(Plexiglass fitted with cast iron pipes to make a carport)

2.Types of Plexiglass

The differences in types of plexiglass arise from the different techniques used in their manufacturing. Confirming that the one you pick fits the intended use is important when selecting plexiglass.

Cast Acrylic

Cast Acrylic is the strongest type of plexiglass and can measure up to 300 mm. It is most suited for constructing strong structures that withstand high force or pressure. You can cut it using a table saw using the correct blade.

Extruded Acrylic

Extruded Acrylic is more flexible but relatively weaker than cast acrylic. It has a wide range of applications because it is easily malleable. You do not need a table saw since you can cut it using a utility knife or bare hands.

Polycarbonate Acrylic

Polycarbonate Acrylic is an intermediate between cast and extruded acrylic, with all its qualities in between the two. The type of material is recommendable in bulletproofing due to its higher resistance to tension and impact.

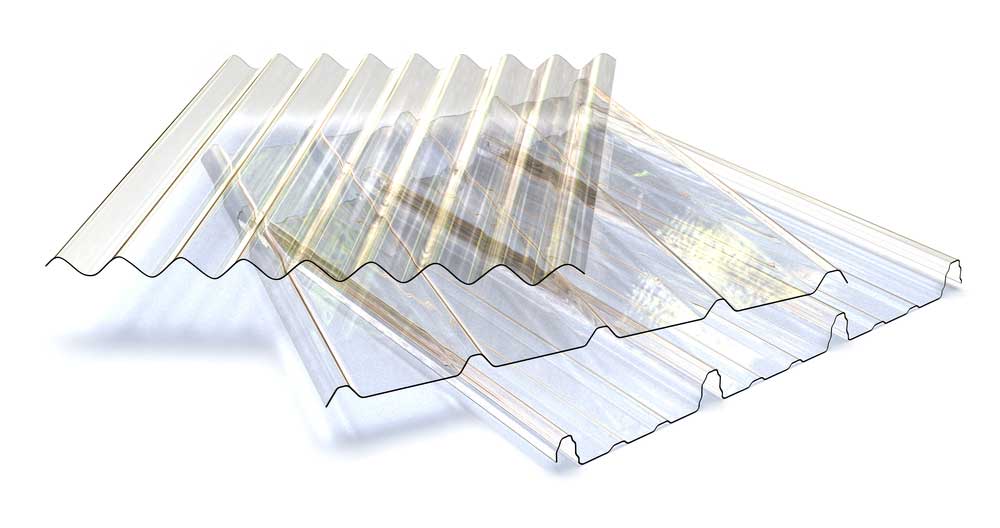

(A transparent board)

3. Strength of Plexiglass

The strength of plexiglass does not lie in its thickness alone but in a list of factors, including its resistance to impact. Compared to normal glass, plexiglass can withstand a larger impact force before it breaks.

(The strength of plexiglass)

4. Cutting Plexiglass Using a Table Saw

Now that you know the basics, let’s get our hands dirty, shall we?

Taking Precaution

Safety comes first; therefore, you must wear protective gear before getting to work.

First, make sure that you are capable of using a table saw. If you need help, read the manufacturer’s guide.

Secondly, put on some safety glasses and a face shield to protect you from the shredded pieces of plastic that may project on your face.

Lastly, put on a hearing protection device. Avoid wearing work gloves.

(Protective gear)

Choosing the Most Suitable Blade

The rule of thumb when picking blades is, “The harder the material, the more the teeth.” The logic is quite simple. More teeth produce higher friction, resulting in a finer cut.

For example, when cutting a thick sheet of plexiglass, you will require a blade with many teeth to provide a clean and smooth cut. Fewer teeth are more effective for weaker materials, preventing the fragile material from chipping.

The following are qualities of a good blade for cutting plexiglass:

- Zero-degree rake (rake is the angle between the blade and its hub)

- uniform teeth in both size and spacing

- The blade should have steel material and the tips of carbide.

- We should have between 60 and 80 teeth.

(Different types of cutting blades)

Thickness of Plexiglass

Plexiglass has different thicknesses ranging from 1/16 inch to 4 inches (1.6 to 101.6 mm). Use sheets over 1/4 inch thick on a table saw because chipping often destroys anything below that thickness.

Measuring the Size You Want

Measure and transfer measurements to the plexiglass on the side with the protective film. Keep the protective film intact during cutting; only move it after installation.

Using a push stick/ push block

A push stick/ push block is a safety device that prevents your fingers from being damaged by the table saw. In addition, it helps hold the material being cut steadily on the fence on both sides of the saw blade.

Ex-exerting a downward force on the plexiglass prevents movement of the plexiglass as the table saw vibrates, which could cause a rough edge.

You can either buy a commercially made one or make your own at home with a few instructions from the internet.

(Use table drama cutting)

5. The Technique for Cutting

- Install the correct blade on the table saw.

- Adjust the height of the blade to half an inch above the plexiglass.

- Place the plexiglass on the table (the side with the protective film facing down).

- Hold the sheet down by exerting pressure.

- Turn on the machine and move the sheet slowly at a feed rate of 3 in/s to prevent chipping.

- Take regular breaks to ensure the machine cools down and prevents the melting of the plexiglass.

- When crosscutting (cutting against the grain), switch to the opposite end of the sheet after going halfway before cutting again to prevent chipping.

(Cut with a circular saw)

6. Alternative ways of cutting plexiglass

Using a Utility Knife

Pass a sharp knife several times (8–10) on the plexiglass along the lines you marked. Snap it along the line of weakness.

Using a Dremel grinder fitted with a cutting wheel

This tool cuts plexiglass where a regular cut is needed.

Jigsaw

This tool allows different cuts: straight, irregular, and circular.

(Utility Knife)

7. FAQs

Can a 1/4-inch plexiglass be cut on a table saw?

It definitely can. 1/4 inch of plexiglass is the lowest thickness that can safely pass through a table saw without chipping.

You can also stack many sheets of plexiglass together to save cutting time.

How are the edges of plexiglass smoothened?

Use of sandpaper Begin with a rough-grit (100) sandpaper, then proceed to a finer one (200) to smooth the edges. Finally, finish with very fine (400) sandpaper for a polished finish.

Skip this step if you intend to glue the pages.

(Different grit sandpaper)

In Summary

You can cut plexiglass on a table saw if you pick the correct blade. Confirm that it has a 1/4 inch or more thickness when using a table saw. Thinner places can be cut using a utility knife or by hand. Now cut some plexiglass like a pro!