What Are Band Saws Used For? A band saw is a staple tool in workshops worldwide and for a good reason.

They’re powerful and versatile tools with remarkable capabilities. However, great as they are, they’re not suited for all kinds of sawing.

In short, it’s essential to know the jobs suited for a band saw and, more specifically, the most suitable band saw type for your project. So what are band saws used for? This article discusses the answer to this and more.

Table of Contents

- Band Saw History

- How Do Band Saws Work?

- What Is a Band Saw Used For?

- What are the Advantages and Disadvantages of Using a Band Saw?

- What Type of Band Saw Should You Purchase?

- Scroll Saw Vs. Band Saw

- What Kinds of Band Saw Blades Are There?

- Common Challenges When Using Band Saws

- Conclusion

Band Saw History

William Newberry invented the band saw and received a British patent in 1809. However, this and many other blade inventions remained impractical because of the blade’s inability to withstand constant flexing.

It was only in 1866 that Frenchman A. Perin introduced a viable blade, which quickly grew popular, spreading throughout the rest of Europe. Later, the tool went to North America, where people manufactured it commercially. And today, artisans worldwide prioritize it in their startup budget.

(Bandsaw at work)

How Do Band Saws Work?

A band saw utilizes a continuous metal loop referred to as a band. The band runs around two wheels, one connecting to the blade/band and the other to the table, moving and guiding the material for cutting.

As the wheels move, the band also rotates, pulling the blade in one direction to cut.

The band’s blade comprises teeth, and blades vary in how they utilize them. For example, some blades have teeth on the inside edges, while others have them on the outside.

Also, different blade types comprise varying tooth sizes to cut through various materials like wood, metals, and plastics.

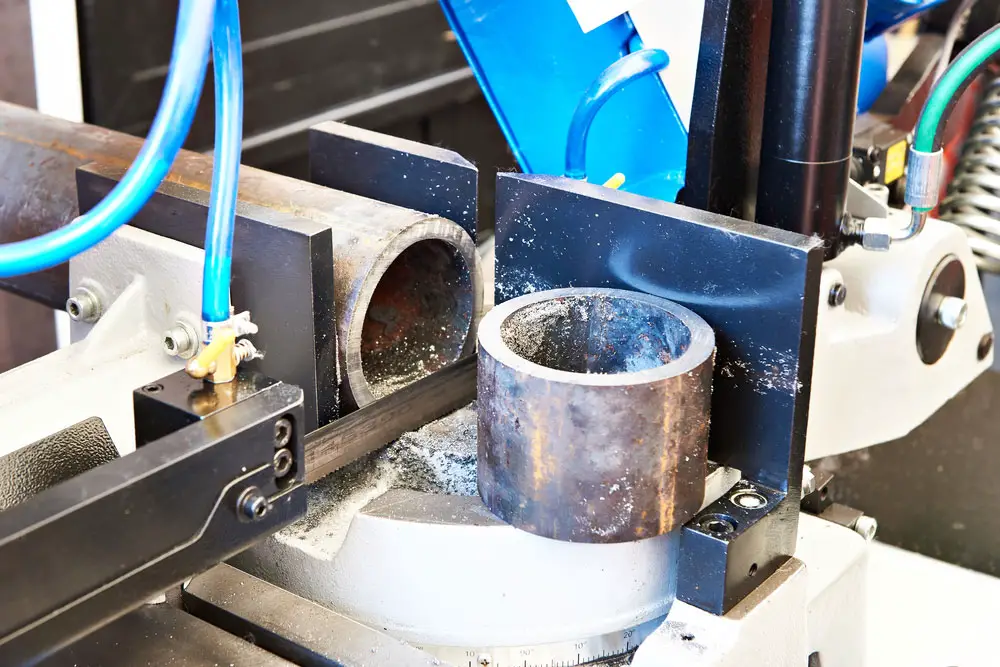

(Band saw cutting steel material)

What Is a Band Saw Used For?

Intricate Cuts

These are cuts done to make shapes such as sharp or gradual curves and angles, typically in artistic designs or projects requiring accuracy.

Rip Cuts

These are cuts parallel to or along the grain of the wood. Typically, rip cuts are deep cuts often done on hard lumber.

Crosscuts

This crosscut is a cut perpendicular to the wood grain. In this case, the board you’re cutting gets pushed horizontally for a straight cut.

Rabbets

Rabbets are recess cuts usually done on the edge of a workplace to expose an extruded piece known as a tongue. And on to this, you affix another piece of wood to form a rabbet joint.

(band saw pictures)

What are the Advantages and Disadvantages of Using a Band Saw?

Advantages

- They’re ideal for making large amounts of identical cuts, which is extremely helpful for high-volume projects.

- A band saw can make different cuts, including intricate cuts, rip cuts, rabbets, and cross cuts.

- The saw can cut different materials, including wood, plastics, and metals.

- The cutting gets done faster, saving time and human labor.

- They’re user-friendly due to the partially encased blade.

Disadvantages

- Because they are very powerful tools, learning to use them properly can take time.

- Because of their large size and weight, they’re hard to move around. Also, they require a large workspace.

- They are not suitable for small and delicate cuts.

- As mentioned earlier, smaller band saws may need more power to cut larger pieces of wood.

(Metal Cutting Band Saw)

What Type of Band Saw Should You Purchase?

Based on what you’re working on and how much room you have, you may choose from the following band saw types::

Benchtop Band Saw

This saw sits on a workbench or countertop, so it’s a good choice if you have limited space. And because it lacks horsepower, it’s more suited for hobby work.

Floor-Standing Band Saw

This one is larger, so you’ll need a big space to accommodate it. Also, it has more horsepower and can handle repetitive jobs and cut large depths.

Further, you can vary the speeds, a highly useful feature for making detailed cuts. For this reason, the floor-standing band saw is suitable for commercial use or large projects.

Scroll Saw Vs. Band Saw

Often beginner woodworkers start with a scroll saw or band saw. However, knowing the difference between the two is important to make the best choice.

(Scroll Saw)

What Kinds of Band Saw Blades Are There?

Generally, band saw blades classification is according to teeth count, blade material, and edges as follows:

- Circular blades: These blades have teeth on both edges (inside and outside). These double-edged blades are best suited for making rip cuts of thicker materials.

- Straight blades: These have teeth on the inside edge only.

- Blades with a higher tooth count: These blades make clean cuts and cut through wood and soft plastics.

- Blades with a low teeth count: Blades with fewer teeth cut well through harder materials.

(Band Saw Blades)

What Band Saw Blade Teeth Types Are There?

There are several types of band saw blade teeth, including: :

- Skip-toothed. This type is widely spaced, often twice as wide as the normal spacing. Such teeth are suitable for making clean cuts since they don’t bite into material quickly.

- Straight-toothed: These are for cutting through thicker material.

- Regular-toothed: These teeth are well-proportioned for general purposes.

- Variable pitch: The teeth vary in size and setting and work best for making curves and fast-finish cuts.

- Raker-toothed: These teeth with a diagonal pattern are ideal for making delicate cuts as they’re less aggressive than other teeth types.

- Hook-toothed: These large teeth with deep gullets are great for cutting materials like thick wood and metals, which require long, deep cuts.

(teeth of band saw blade)

Common Challenges When Using Band Saws

How Do You Make a Cross Cut With a Band Saw?

To make a crosscut with a band saw, you must push the wood into the moving blade while ensuring that the blade is perpendicular to the wood’s grain.

If the wood you’re cutting is larger than your workbench, the board will stop moving before you can finish your cuts. To counter this, you must use clamps or wedges to support the end of the board.

Can You Make a Curved Cut With a Band Saw?

Yes, you can. But to make the job easier, you might want to make a rip fence for your band saw.

Also, use a large blade (at least half an inch wide) with a low tooth count. In addition, ensure the blade is properly centered and supported.

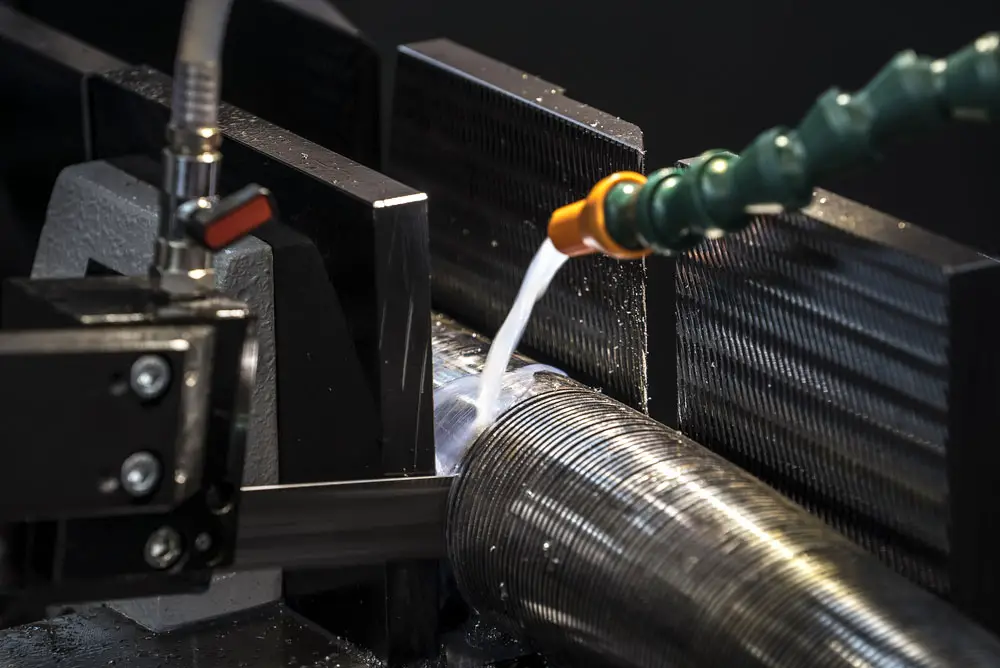

What Is a Deep-Cut Band Saw Used For?

This saw is ideal for making long, clean, and straight cuts. Usually, you’ll find this saw in metal shops as metal workers use it to fabricate metals and cut all sorts of metal bars and sheets.

(Deep-Cut Band Saw )

Conclusion

From its introduction 200 years ago, the band saw’s features, capability, and efficiency have evolved. And today, the tool is useful to skillful artisans working with wood, plastics, and metals.

As we have seen, the band saw’s versatility is stunning, and it’s no wonder this tool is essential to many craftspersons. For more information on band saws and other workshop accessories, contact us.