Regardless of the project you have at hand, getting it done rightly matters a lot. Using the right tool for a job helps to reduce fatigue and increase your overall efficiency significantly. When making a core cut, the appropriate means must be selected and used for your project.

This article will discuss tips for choosing the right cut core saw for your jobs in concrete, masonry, asphalt, etc. By the end of this read, we expect your knowledge about concrete cutting saws to have increased.

Table of Contents

- 1. Size of the job

- 2. Choose the right type of blade

- 3. Ensure the saw meets all power requirement

- 4. Consider your budget

- 5. Choose quality over quantity.

- Conclusion

Fig. 1: Concrete cutting operation ongoing.

1. Size of the job

The need to consider the complexity and volume of the job a hand cannot be over-emphasized. The size in terms of thickness and length of the concrete goes a long way in helping you choose the cut core saw. There are two forms of the concrete cut saw: the handheld and the walk-behind saw.

- Handheld Saw

As the name implies, this core cut saw is easy to use, simple, and straightforward for short-term jobs. Its portability and handiness make it a favorite pick among users.

If you are working indoors, then this is just what you need. With the hand-held core cut saw, you can work flexibly. Without compromising accuracy, this concrete cutting saw works like magic on your concrete slabs or asphalt walkways.

Whenever you have small and shallow cutting jobs, this easily fits into the job and delivers reasonably well. Bear in mind that with this saw, you can cut in any convenient position/posture.

- Walk-Behind Saw

Again, this is another amazing concrete saw deployed majorly for outdoor and large jobs. Its design is such that it gives the total user control over it when in use. It’s not as portable as the Handheld as such an ergonomic handle is attached.

It looks exactly like a typical lawnmower except that the blade is strapped on the side and not underneath. The walk-behind saw comes to mind for long and continuous hours of usage.

Whether for dry-cutting or wet-cutting concrete, it’s always good to go. However, you should purchase this if you have a large project, especially medium to high-range civil works.

Fig. 2: Man operating wet-cutting concrete using a hand-held saw.

2. Choose the right type of blade

By default, Diamond blades suit concrete and asphalt cutting. Manufacturers have engineered them to penetrate very hard materials without breaking.

However, using a diamond blade for your cut core saw is insufficient. Using that with the correct configurations and characteristics is far more important. These characteristics cut across the following:

- Wet-cut or Dry-cut

Wet Diamond blades have come to stay in the world of cutting. They are known for their ability to withstand constant spray of water on them during cutting. This singular act averts many impending calamities and hazards to you or your workpiece.

Minimal heat and dust are generated, reducing the friction and wear of diamond crystals around the part. They remain the fastest and most accurate saw blades for concrete and asphalt cutting.

On the other hand, Dry diamond blades are characterized by lesser teeth per inch to enable effective cooling. When employed for deep cuts, it has to follow successive steps of shallow cuts.

- Tooth per inch

Wet diamond blades have higher teeth per inch since they are water or lubricant cooled. While the Dry diamond blade has a more serrated tooth arrangement with fewer teeth per inch, this feature helps the dry diamond blade cool and eject chips and dust easily.

- Blade speed

One cannot be too careful about matching the speed of bade to that of the core cut saw. Whether you want to use a hand-held or walk-behind saw, ensure your blade speed is greater than the concrete saw’s maximum speed. It helps to avoid an accident due to over-speeding and imminent breakage of the blade.

Generally, thicker core materials require larger blades, and higher tooth-per-inch blades give a cleaner and more accurate cut.

Fig. 3: Dry-cutting operation using the hand-held concrete cutting saw.

3. Ensure the saw meets all power requirement

Based on the material in question, i.e., concrete or asphalt, the saw chosen must be powerful enough for this purpose. A check and balance of the speed, type of drive to the nature of the material must also come into play.

As of today, powering core cut saws has evolved rapidly through various innovative methods. Some power saws are- driven by an Internal combustion engine, electric motors, or rechargeable batteries.

Rechargeable battery saws hardly produce enough power required by a diamond blade to cut concrete or asphalt. Hence, the reason for their rareness in this regard.

Although, technological advancement has seen the rechargeable saw adoption for heavy cutting jobs. You would have to select one with high battery capacity and probably carry a spare too.

However, the best power source for core cut saws is the internal combustion engine or electric motor approach. For ICEs, a gasoline engine is mounted on the saw to deliver the torque and power to the blade.

Here, the engine’s output determines the input to the blade and automatically to the workpiece. Electric motors derive their input from the electric mains supply to produce rotational energy and torque for the blade.

Generally, the engine-powered saw is the best bet for outdoor use, either for dry-cutting or wet-cutting; it is your best choice. It is known for its high durability embedded in its rugged design.

On the other hand, electric-powered saws are best for confined and indoor spaces. It is because it does not produce fumes or pose a risk of fire outbreak.

It is also best suited for dry-cutting operations. Furthermore, the absence of an engine drastically reduces the amount of noise produced.

In the two cases above, special power transmitters come into play. Gears, chains, or belts come into play for transmitting the energy produced by the ICE or electric motor to the blade arbor.

Above all, decide which best suits your cutting need before purchasing.

Fig. 4: A brand new walk-behind saw showing the internal combustion engine.

4. Consider your budget

This factor is often a limiting one for intending buyers of core cut saws. Considering the above-listed basic requirements, you must decide based on your purchasing power. It is best that you “cut your coat according to your size.”

Buy the best saw your money can get you, which should also meet at least 70% of your basic need. While sticking to your budget, you should not compromise other factors that would help you land a great saw.

It would be best to strike a balance between your budget and your ultimate goal for purchasing the saw.

The right saw makes it easy to cut. In turn, the ease of cutting helps you achieve the best cut. You could also consider rentals if you are not a contractor or regular user of the core cut saw.

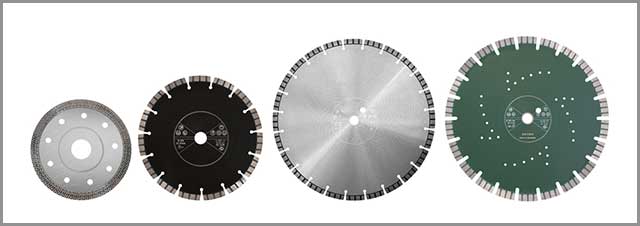

Fig. 5: Set of concrete cutting saw.

5. Choose quality over quantity.

Just like in every other walk of life, quality is far more paramount than quantity. When selecting your concrete cutting saw, pay attention to the ingenuity in design.

It is in your best interest that you not only focus on the price of the saw but also the value derivable. Emphasis should always remain on prudency when preparing to purchase a core cut saw.

Go for brands of saws and blades with a track record of durability and ease of use before considering the price. As a first-timer, you can consult friends for assistance and advice.

Once you take the pain to purchase a quality saw, rest assured you will gain high utility. When carrying out your research, go for brands and companies with registered trademarks and a track record of excellence. In short, never settle for less; with NCCuttingtools, you can get 100% value back for your money spent.

Fig. 6: Set of Diamond blades.

Conclusion

Finally, rest assured that you are good to go once you religiously follow the tips discussed in this article. At NCCuttingtools, our core value is providing cutting-edge technologies across cutting tools and related equipment.

If peradventure, you desire to gain more useful tips and knowledge in this domain, consult this video here.