Regarding the choice of the saw blade, I believe you have a lot of doubts. Using the pre-fitted saw blade for your table, chop, radial, or sliding compound miter saw might be very tempting. However, if you want to continue making smooth, safe cuts using your saw, you NEED to select the proper blade.

That is why we recommend TCT saw blade. While all saw blades are designed to make different kinds of cuts, you do not need a particular module for each. That makes TCT blade saw blades for wood and metal the best knife for you.

In this article, we will introduce the advantages of TCT saw blades. Let us know about this tool together!

Table of Contents

- 1. A brief introduction to TCT saw blade

- 2. The application range of TCT circular saw blade is vast

- 3. TCT saw blade can stay sharp for a long time

- 5. TCT circular saw blade longer life

- 6. If damaged, replace the TCT saw blade

- 7. TCT saw blade can better grasp the angle

- 8. You can still choose different TCT circular saw blade sizes

- 9. For cutting hard materials, TCT saw blades are more suitable.

- 10. All operations are within the safe range.

- Summary :

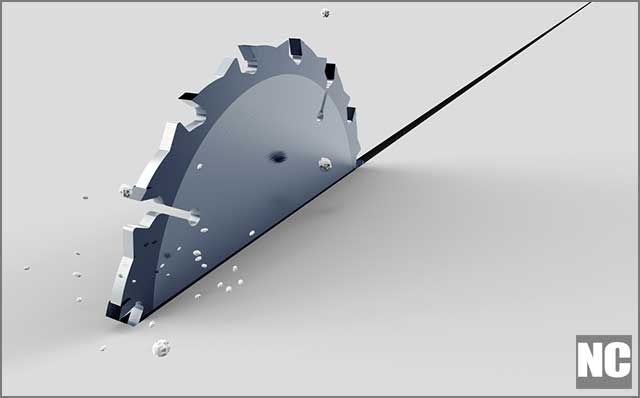

1. A brief introduction to TCT saw blade

A TCT (tungsten carbide-tipped) blade is a re-sharpened circular saw blade. They come with a gear reduction and an electronic motor. It allows the user to maintain consistent torque while reducing the saw blade’s rotational speed. As a result, the blade has a high chip load per tooth while feeding at a constant rate. The following items can use TCT saw blades: wood, some ferrous metals, non-ferrous metals, and plastics.

In general, circular saws are toothed blades designed to cut metal. Regarding the TCT saw blade, these teeth are coated in tungsten carbide, allowing the module to cut metals quickly. It also prolongs the life span of the TCT, allowing it to stay sharper longer than your average blade.

The teeth on this kind of knife are also replaceable and are primarily used to transfer the heat generated by cutting chips created by the saw blade. It allows the material to be cut and the edge to remain calm.

(TCT Cutting Blade)

2. The application range of TCT circular saw blade is vast

TCT circular saw blades are used widely in several industries, namely for heavy applications involving titanium, cobalt, nickel, and zirconium. Some of these applications include:

- Cutting sections

- Metal tubing, rails, and pipes

- Heavy-duty jobs such as these are specific to:

- The railway industry

- Steel pipe industry

- The wood industry

- The aluminum industry

If you work in any of the fields above, TCT saw blade would help you. Of course, if you work with any of the materials listed above, TCT saw blade could also greatly benefit you.

(Applications of TCT saw blade)

3. TCT saw blade can stay sharp for a long time

If you are tired of wasting money on saw blades with short life spans, TCT saw blades are well worth the investment. Generally, they are classified as cold saw that stays sharper for extended periods. These blades are in high demand because they allow you to adjust the module’s cutting speeds and feed rate.

It offers more cutting control than most blades, and you can change the tool based on the type and size of the material you are cutting. Additional advantages include:

- Minimal burr production

- Spark reduction

- Less discoloration

- No dust

- Both spark and discoloration reduction are made possible by the flood coolant system that keeps the saw blade and the material fresh.

(Worker is using TCT saw blade to cut items)

5. TCT circular saw blade longer life

TCT blades typically last four times longer than the average blade. It is made possible by tungsten carbide.

• What is tungsten carbide?

Tungsten carbide is a chemical compound that, when pressed, is two times stiffer than steel. Carbide tools maintain sharpness, produce better finishes, and are temperature resistant. It makes TCT saw blade ideal for cutting metal.

• Another advantage of these blades is that:

If the blade breaks or is misplaced, it can easily replace it. Suggestions are also available in different tooth sizes, carbide grades, and coatings that can temper to work for a lifetime.

How to extend the life of the saw blade? If you are interested, you can refer to this article.

(High-quality TCT saw blade)

6. If damaged, replace the TCT saw blade

Whether you use a TCT saw blade once every day or only on the weekends, there will come a time when you need to replace the blade. The fact is, no matter what saw blade you end up buying, you must keep it sharp. Since no indicator tells you when your knife is dull, it is up to you to make that determination.

If tearing, chipping, bundling, excessive burning, and slow and painful advancement are common signs, it is time to replace the saw blade. For TCT saw blades, this is easy because their tips are replicable.

Making additional cuts with a dull blade is more trouble than it’s worth. Not only will you be wasting your time, hard-earned money, and energy and placing unnecessary stress on the motor bearings of your saw, but it is also perilous to do so.

However, using the TCT saw blade dramatically decreases the number of times you have to do so per project. You run the risk of overheating the material you are cutting, making gluing pointless. In short: once you notice any wear, replace them immediately.

(Better TCT Saw Blade Staff)

7. TCT saw blade can better grasp the angle

A right blade can cut at various aspects, and the TCT Saw Blade does this well, primarily through the wood. As we mentioned above, this saw blade produces no sawdust. It is due to the gear reduction and electronic motor that creates a high chip load per tooth.

While blade angles vary depending on the manufacturer, the most common cut types are 30, 45, and 60 degrees. TCT wood-cutting saw blades are not as limited as other saw blades. It makes them ideal for projects across several industries using different materials.

(TCT saw blades running straight)

8. You can still choose different TCT circular saw blade sizes

As for size, there are no restrictions on TCT saw blades. They come in a variety of sizes. The number of teeth varies per blade as well as the profiles and diameters of the blades. While these sizes are not restricted, their teeth are typically between 180mm and 350mm in diameter. The number of removable teeth per blade is between 24 and 90. No matter the size, you should select saw blades according to the size of your project and what material you are cutting.

(TCT saw blades of different sizes)

9. For cutting hard materials, TCT saw blades are more suitable.

We design TCT saw blades specifically for cutting hard materials. These materials include :

- Non-ferrous metals like aluminum

- Brass

- Cobalt

- Copper

- Lead steel

- Tin

For example, TCT saw blades are great for cutting many shapes, including rods and tubes, Typically made of these materials. The high-power motor and high torque make the TCT blade ideal for these jobs. However, they are also widely used to cut plastics and wood. It is made possible by the stiffness of the teeth on the saw blades, which comes from the tips coated in tungsten carbide.

(Industrial engineer engaged in cutting metal and steel with sharp TCT saw blades)

10. All operations are within the safe range.

If you want a blade for your project with minimal safety risks, TCT blades are a must. TCT blades solve a lot of problems that may occur during projects. Since they are within the safe range, they are in high demand. They decrease the amount of sawdust, sparks, and wood-burning per project and last four times longer than most blades. It ultimately makes any project you start four times safer.

At the same time, when you run the TCT saw blade, you need to protect yourself. Wear goggles, earplugs, cut-resistant gloves, etc., to protect yourself.

As a TCT saw blade supplier, we sell China TCT saw blades. Our TCT wood-cutting saw module is one of many products amongst the 1000 varieties of product systems we offer as a supplier. That said, we know the material you need to cut plays the most significant factor when deciding the kind of saw blade you’ll need. Since TCT saw blades are meant to cut everything from lumber to metal and can use across several industries, we highly recommend them. Overall, they stay sharper for longer, run at higher surface speeds, and are suitable for light and heavy-duty projects.

(Worker wearing protective gloves)

Summary :

Whether you work in the wood, metal, or construction industry, TCT blades can significantly benefit you. They are safer, last longer, produce better finishes, and are more versatile than the standard saw blades. With a large variety of sizes, choosing the proper TCT blade for your project is well within sight.

Here at NCCuttingtools, we can provide you with all your TCT needs. We also have services corresponding to your project needs. We have the background, experience, and tools you will need to complete your projects successfully.

Using the wrong saw blade affects your quality, time, money, and safety. You can contact us immediately, and we will help you choose the most suitable blade.

If you’re cutting metals, invest in a TCT blade today.