Newbies to the world of cutting and machining often confuse Countersink VS Counterbore. Even though these two words are quite similar, there is still some difference.

These differences affect the usage of screws and bolts and the shape of the holes they make. Hence, this article aims at highlighting the core differences between these two styles of drilling holes.

Also, by the end of this read, we hope you have learned how to make holes using both methods successfully.

Table of Contents

- 1. What are countersink and counterbore?

- 2. Are there many styles of countersink?

- 3. What are the differences between the Countersink VS Counterbore?

- 4. Countersink VS Counterbore– What tools can make a countersink?

- 5. Countersink VS Counterbore– When should we use a counterbore?

- 6. Countersink VS Counterbore– Which Way is the Easiest?

- 7. Countersink VS Counterbore– Frequent Q&A

- Summary

Figure 1: Cross-section of counterboring and countersinking bits

1. What are countersink and counterbore?

These two methods create holes, but as they differ in shape, so does the respective fastener. You must understand these two to know which option fits your project.

Counterbore or countersink simultaneously refers to the cutting tool and the hole itself. Thus, you should consider both terms’ dynamic usage in this article’s subsequent part.

What is a counterbore?

A counterbore produces a cylindrical hole with an enlarged flat head such that a fastener’s head will flush fit. A Forstner bit drills the hole following a specified depth and diameter.

A prominent feature of the counterbore is that the hole’s diameter is slightly lesser than that of the fastener’s head. The counterbore usually has two distinct cutting radii.

One is for the actual counterbore, and the other is for the recessed cavity. An interesting feature of a counterbore is that it helps to conceal the fastener when joining parts.

What is a countersink?

A countersink produces a conical hole at an angle that matches that of the screw head to allow a flush fit. Similarly, the flush fit is to either the workpiece surface or slightly below.

There are several styles of countersink for different purposes and applications. Besides, a countersink can help deburr or create chamfers on a workpiece.

A striking feature of the countersink is that it looks V-shaped. Generally, to use a tapered head screw, you must already have a countersink in place. Many properties define a countersink, such as; diameter, depth, and angle.

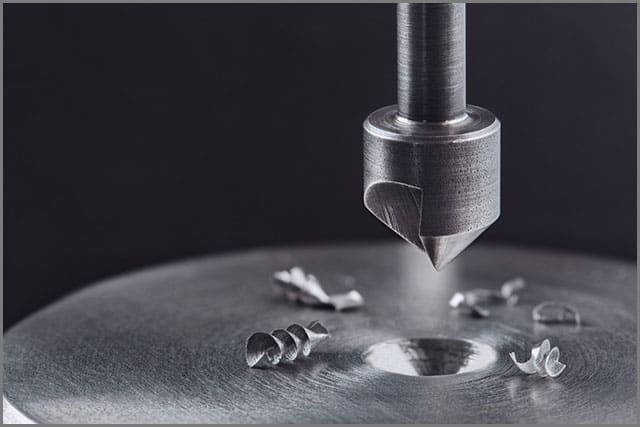

Figure 2: Close-up image of a countersink.

2. Are there many styles of countersink?

Yes, because of the demand for various areas of application of countersinks, many styles exist. These styles vary specifically due to the angle of the cut.

Also, each style comes with its distinct advantages over others. Below are the various standard angle sizes of countersink available in the market today with their respective applications:

- 60° for deburring

- 75° for rivet heads

- 82° for US standard countersunk screws

- 90° for countersunk screws

- 120° for countersinking of sheet metal rivets

- 180° for cylindrical and hexagonal head screws and nuts.

Furthermore, a detailed examination of the various styles of the countersink is as follows:

Cross-hole cutter

This countersink is special because of its unique drill hole across the countersink. It features a hole at 45° to the countersink’s axis but a countersink angle of 90°.

The hole at 45° helps to take out chips quickly. It prevents jamming and keeps the workpiece clean. They are also the best choice of countersink for deburring.

Figure 3: Countersink showing its drill hole for chip removal.

Flat Countersink

It cuts a cylindrical shape at 180° for cylinder and hexagonal head screws and nuts at this countersink’s tip. The guide goes first goes into the pre-drilled hole for precision.

There exist two broad categories of flat countersink. These are for-through and thread core holes. They differ in their mode of fastening two separate workpieces together.

Only the second material is threaded through holes, while both materials are in the thread core hole. Again, the for-through hole’s fixed guide diameter is often larger than that of the thread core hole.

Shell sinker

A shell sinker has its countersink mounted on a twist drill. The setup is such that initial drilling and countersinking happen in one working step.

3. What are the differences between the Countersink VS Counterbore?

There exist some distinct differences between the countersink and counterbore. We have highlighted some of these differences, here they are below:

3.1 Shape

The shape of the hole produced by a counterbore is straight, while that of a countersink is V-shaped. Also, you could say that the counterbore is cylindrical, while the countersink is canonical.

The key difference between countersinks and counterbore lies in their shape. Thus, from physical inspection, you should recognize both hole types.

It is worthy of note that a countersink produces a narrower hole than its head. On the other hand, a counterbore is the same diameter all through.

Figure 4: Countersink showing its canonical/ V-shape.

Figure 5: Threaded and Un-threaded Counterbore showing its cylindrical shape.

3.2 Type of fasteners

Due to the nature of the countersink or counterbore, the type of fastener used automatically differs. Countersink will always have canonical-head f fasteners, while counterbore has flat-bottom fasteners.

Examples of counterbore fasteners are hexagonal head screws and bolts, nuts with end bolts, etc.

3.3 Application

More often than not, wood as a material is quite easy to force-fit canonical head fasteners. It automatically makes the essence of countersinking useless in woodwork.

Hence, countersinking is best adapted for metals, PCBs, and other less flexible materials; counterbore is more synonymous with wood and harder to carry out.

The reason for this is that counterbore usually has much larger heads.

4. Countersink VS Counterbore– What tools can make a countersink?

The simple tool used to form a countersink is also called a countersink. However, it is sometimes referred to as a countersink tool to eliminate confusion.

These tools come as either manual or power-driven. Your usage and application should guide which version you purchase. Heavy jobs require more power to drive deeper.

All you need do is, consider the complexity of your job and purchase a good set with different sizes.

4.1 When should we need a countersink?

Primarily, once your choice of a fastener is a tapered one, then a countersink is compulsory. Besides, the perfect flush of the fastener’s head to the workpiece surface always gives your work a fine finish.

More so, a countersink will ensure that your fastener can go full length into the workpiece. It will ensure a perfect fit and strong joint without breaking the workpiece’s surface.

Conclusively, a countersink adds more aesthetics to your job and averts likely cuts or tears to the skin or clothing.

5. Countersink VS Counterbore– When should we use a counterbore?

A rare case of having a fastener not long enough can be solved easily with a counterbore. When fixing two workpieces, they have a thickness greater than the available fastener’s length.

The counterbore proffers a solution by ensuring that the hole is sufficient to fasten only. With a counterbore, you can fasten without allowing the fastener’s head to interfere.

Even though the counterbore does not increase the fastener’s length, it still helps you achieve the end goal. It happens when the hole equals the fastener’s threaded end while the head keeps below the workpiece’s surface.

5.1 What tools can make a counterboring?

Unlike the countersink, a Forstner bit produces a counterbore. These bits come in various diameters and make precise holes with straight edges. The typical bit size ranges from ¼’’ up to 1’’ on the market.

6. Countersink VS Counterbore– Which Way is the Easiest?

Honestly, no method is the easiest; countersinking and counterboring require a similar effort. It can do it manually or with power tools.

Although, it is only woods that the manual method would be easy to use. Other materials will require the use of a power-driven tool.

Recall that wood is softer, delicate, and easier to ruin, hence manual over the power-driven tool. The manual approach gives you more control over the drilling;

however, you want it more than the power tool. For convenience, countersink for a tapered head fastener and counterbore for a T-shaped head fastener.

7. Countersink VS Counterbore– Frequent Q&A

Learn about some important questions mostly asked about counterbore and countersink below

7.1 What does deburring mean?

Purdue result of the small shreds of materials left after drilling a for-through hole. Burrs are dangerous, especially if they are metallic.

Therefore, the process of removing these burrs is termed deburring. A countersink with an angle of 60° helps carry out deburring successfully.

Deburring helps to widen the hole’s entry region through countersinking and aids the internal threading of the hole.

7.2 How do we determine the dimension of the Countersink VS Counterbore?

For both the counterbore and countersink, follow the steps below to determine its dimension:

- Measure the screw’s diameter and divide it by two to get the radius.

- Calculate the area of the circle through ℼ× (radius)2.

- From the result in (b) above, multiply again by the screw’s length.

- The result from (c) gives the appropriate depth of the countersink you need.

Additionally, for a counterbore, the Forstner bit does the job. The design is such that the pilot has a reduced diameter than the fluted end. For a countersink, use one that corresponds to the angle you desire.

Summary

In conclusion, this article has enumerated the differences, similarities, and intricacies of counterbore and countersink.

For all your cutting tools, custom product, and services, reach out to us now at NCCuttingtools. We will gladly offer our professional consultancy to you anytime, any day.