As a distributor, it is a challenging thing to customize tools. There are so many factors and considerations to consider regarding the tools you need to customize, and missing out on a single detail could lead to many errors.

The good thing is you know this, which is why you are reading this article; you can customize the best functional tools and avoid making any mistakes as you work.

This article is the guide to show you all you need to know about custom industrial equipment stone saws.

Table of Contents

- 1. Industrial Equipment Stone Saw-Make Sure You Know Your Cutting Materials

- 2. Precisely Match Your Industrial Equipment stone saw

- 3. Industrial Equipment Stone Saw-Choose the right Teeth Density

- 4. Industrial Equipment Stone Saw-You Need to Customize Several Sizes

- 5. Industrial Equipment Stone Saw-Find Out if You Need Precision Saw Blades

- 6. Accurately Make Choices of Custom Industrial Equipment Stone Saw Suppliers

- 7. Ensure the Length of Service Life

- Summary

1. Industrial Equipment Stone Saw-Make Sure You Know Your Cutting Materials

(Wet-cutting a granite boulder)

A stone saw would behave differently depending on the type of materials you need to cut. Why do you need to keep this in mind when customizing any industrial equipment stone saw? There are stone saws for cutting granite, stone blocks, bricks, etc.

Like a good dealer, you need to know which cutting materials you would be using the stone saw for so that you can customize it to suit that purpose. Depending on the hardness or roughness of the content, you might need some particular blade types.

Granite materials would need a particular type of blade and cutting procedure. For example, granite requires a particular dry blade for cutting. Stone blocks and bricks also need a masonry saw. The materials are the primary determinant for getting any stone saw.

Accurate knowledge of the different types and their uses would help you properly customize you for use as industrial equipment stone saw.

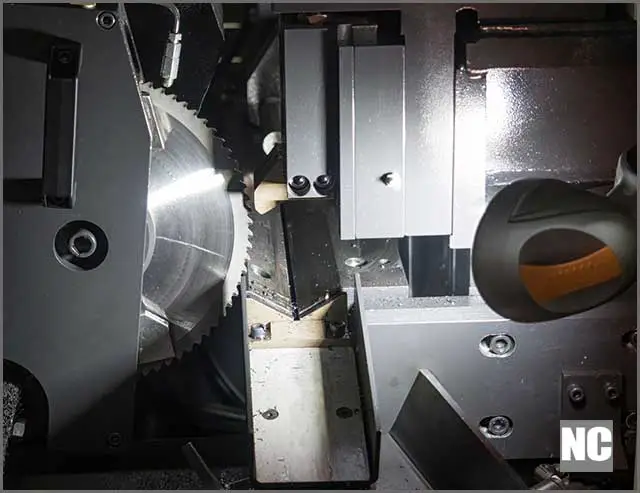

2. Precisely Match Your Industrial Equipment stone saw

(Industrial cutting saw blade)

Not only do you choose the right type of blade, But you also need to get the right blade size based on the cutting material you want to customize. Customized stone pieces must match the industrial equipment, which may cause it to malfunction.

One way to know which type of blade to choose is to look for the one that explicitly indicates the stone saw that it is for cutting. Some tips and guides can help you choose and pair the right industrial equipment. Many stones saw brands have them.

You may also want to go through these tips and guides to see how these machines work; this would help you to have a better idea of what you are working with so that you can do a thorough and precise customizing job.

For more information, You may learn more about each type of saw and the most suitable material type. This way, you can choose the best tools that would match your industrial equipment.

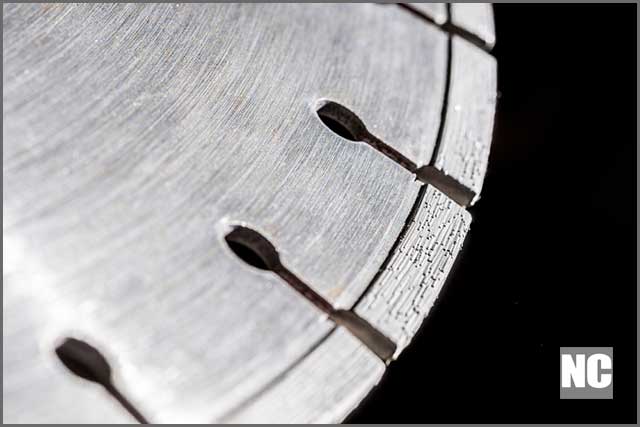

3. Industrial Equipment Stone Saw-Choose the right Teeth Density

(Close-up shot of stone saw teeth)

For all types of saws, including stone saws, knowing and choosing the proper tooth density helps greatly when you want to customize stone saws for industrial equipment. The wrong teeth density can make the tool problematic rather than helpful.

Although many saws can use the same tooth or blade density as other tools, it is not all the time that this works. If you are unsure whether the teeth density is suitable for the stone saw, you should find out before using it.

There are various types of tooth density; these are suited for different purposes and have different requirements. What works on a material may utterly ruin another type of content, or even the blade teeth itself no matter how similar the stuff your stone saw would be cutting looks.

You will often find that the type of blade your stone saw will need is already on your saw. It is important to note that when it comes to saw blades, the more teeth it has, the more accurate and more beautiful the cuts will be.

4. Industrial Equipment Stone Saw-You Need to Customize Several Sizes

(Contractor table with planning tools and materials)

When we talk about ‘size’ when dealing with stone saws, we’re referring to the blade diameter. Blade diameter is an essential measurement to take note of when customizing stone saws for industrial equipment.

Different types of saws would use different kinds of blade diameters. So because the blade size would determine the depth of material you can cut. In simpler terms, the thickness of the type of content you need to cut will determine the size of your blade.

Some stone saws can use smaller blades, while others use larger leaves. Depending on the type of stone saw, you will find saw blade ranges of different sizes. For example, standard tile saw sizes are between 7-10 inches.

To make custom industrial equipment stone saws, consider that different cutting needs require different blade diameters. Therefore, customize saws of various sizes rather than sticking to one size only. It will give you versatility.

5. Industrial Equipment Stone Saw-Find Out if You Need Precision Saw Blades

(A Carbide-tipped Precision Saw)

Stone cutting essentially needs precision cutting; to achieve this, you need the right equipment. Precision saw blade designed for specific purposes and manufacture – ultra-fine cutting. Precision saw blades are unique. They have beveled teeth on the face and the top.

Precision Saw Blades increase productivity and boost cutting operations in general. The type of precision blade used for cutting varies based on the stone saw in question. For an excellent job of customization, you need to find out if you need any precision saw blades.

If you find these precision blades necessary for a stone saw, then you can customize them according to the usual work needs.

6. Accurately Make Choices of Custom Industrial Equipment Stone Saw Suppliers

(An industrial factory worker cutting granite marble)

Another vital thing to note when customizing a stone saw is supplier selection. In choosing your supplier, you need to critically examine who they are and consider if they have proven themselves in the supply of the workforce for your customizing purposes.

For smooth services and operations to run, your supplier has to be reliable and satisfactory, thoroughly understand your needs and that of the business, be cooperative, and offer competency and professionalism. The supply of the workforce has to meet or surpass your expectations.

It also has to fit the peculiar needs of the business for there to be productivity. One more thing you should know about choosing a supplier is to have a supplier that provides the equipment needed for custom-made industrial equipment stone saws.

Choosing this supplier may be based on the intensity or frequency of demand. Your supplier must always be able to meet up with the requirements of the business. There is no use keeping a supplier around if they don’t provide the equipment you need when you need it.

To make these choices, you may have to thoroughly research the industrial equipment stone saw suppliers on the market and pick the best fit.

7. Ensure the Length of Service Life

(A completely assembled stone saw ready to use)

Finally, the last thing you should know about stone saw customization is to pay attention to the product’s life. Although blades do not usually have an expiry date or period span, they tend to get worn out and blunt over time.

Many factors are responsible for the service life of a saw blade. The first is quality. According to experts, a low-quality module only lasts about 12 hours of nonstop cutting, while high-quality blades last up to 120 hours.

Another factor affecting service life is the material you are cutting. As you know, we use concrete and stone saws for coarse and harsh materials; they are more likely to wear a blade down than materials like wood or glass.

Cutting techniques are also known to shorten or increase your product life. Wet-cutting, which we often use with stone materials, makes your blade dull quickly, while dry-cutting will give it a longer life span.

Check their Rotation per Minute (RPM) when purchasing stone saw blades. Its RPM is necessary because exceeding the normal range of a blade’s RPM can reduce its life span and cause it be damage.

Taking note of all this will help you to keep track of a blade’s product life and keep it sharp and in the best condition for a long time.

Summary

It’s pretty serious business in making custom industrial equipment stone saws. But all of that can become easy when you know the basics. Pay attention to your cutting materials and rightly pair your industrial equipment.

Customize various sizes of blades, and get precision blades if you need them.

Next, be sure to choose a supplier that would provide an adequate workforce and industrial equipment when need be, and finally, ensure that you check and maintain the product life of your tools.

If, however, you feel all this is too overwhelming and you need a helping hand, don’t be alarmed. Facilities such as NCCuttingtools provide distributors and dealers with superior services, including experience and strength.

Be sure to contact them if you feel stuck or unsure what to do at any point in your enterprise.