In recent times, the rising need to carry out rare cuts birthed the development of new tools. Scroll saw blades have helped solve so many cuttings problems around the globe, which may appear arduous.

Scroll saws look and operate exactly like the common cloth and shoe sewing machine. However, instead of bearing a needle and thread, they carry a scroll blade that cuts intricate designs.

Furthermore, scroll saw blades come in various types for specific purposes depending on the task at hand.

This article focuses on the scroll saw blades to shed light on how to choose the correct type.

Table of Contents

- Section 1: What is a scroll saw?

- Section 2: What do we need to consider before buying a scrolling blade?

- Section 3: Do I need pin-end blades or pin-less blades?

- Section 4: Which types of scroll saw blades do we need?

- Section 5: How do you choose the right scroll saw blade size?

- 5.1 As the thickness or density (hardness) of the wood increases, so does the scrolling blade.

- 5.2 Larger scroll saw blades (#9 and above) are more durable.

- 5.3 For thin wood, using a smaller blade is a good choice (3# or smaller blade).

- 5.4 Select the blades based on the thickness of the stack if you want to make stack cutting.

- 5.5 Consider the intricacy of the cuts.

- Section 6: How do we use scroll saw blades correctly?

- Section 7: What materials can the scrolling blades cut?

- Summary

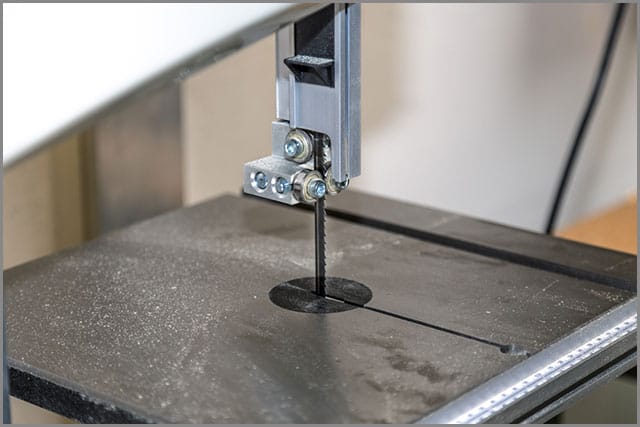

Figure 1: A scroll saw showing its table and blade.

Section 1: What is a scroll saw?

The basis for the invention of a scroll saw lies in cutting intricate designs on wood and metal. Whether for straight or bevel cut, the scroll saw table delivers the best.

You can switch between the speed you desire, depending on the job at hand. They can make about 400 to 1800 strokes per minute with just the rotation of a knob.

While many confuse the scroll saw for a jigsaw, the difference lies in the ease of handling. Unlike the jigsaw, which is hand-controlled and portable, the scroll saw is heavy-duty and comes with a pedal.

Moreover, the ability of the scroll saw lies in the small blade it uses.

Primarily, there exist two broad categories of the scroll saw blades: pinned blade and pin-less blade. The nomenclature adopted for the blades has nothing to do with having a pointed edge. Instead, it refers to how the blade connects to the machine.

Figure 2: A modern scroll saw.

1.1 How is the scroll blade made?

Just like other manufactured blades, the scroll saw blades have different types made of different materials. The material used for making scroll saw blades would later affect the strength of such a blade.

Two scrolls saw blades in existence include; the Ground hardened steel, and Milled Scroll saw blades.

1.1.1 Ground hardened steel blades

Scroll saw blades made from hardened steel have higher strength with a finer and straighter cut from experience. Also, these scroll saw blades offer longer durability up to three or four times more than others.

One very key property of this class pf scroll saw blades is that they are stone-ground. It implies that they will have sharper edges, cut very smoothly, and produce no chip.

1.1.2 Milled scroll saw blades

Normally, this type of scroll saw blades should have almost identical characteristics as the Ground hardened. However, the mastery of the manufacturer when producing determines the outcome.

The milling process involves hardening and tempering of softer metals, called metal flow.

Thus, the manufacturer’s ability to control the metal flow will determine the quality of the scroll saw blades eventually. Ultimately, purchasing from a manufacturer with a track record of proven quality is what matters most.

Section 2: What do we need to consider before buying a scrolling blade?

Surely before purchasing scroll saw blades, some factors must be considered to avoid costly mistakes.

2.1 Is the blade compatible with the machine?

Undoubtedly, compatibility goes a long way in the usability of different blades with a scroll saw. While some manufacturers have produced their saw for specific blade type, others make their universal.

Again, some scroll saws have provision for pinned or pin-less blades. Eventually, it would be best if you chose scroll saw blades that will fit your saw specifications completely.

2.2 Material (Thickness, density)

Depending on the nature of your workpiece, the type of blade to choose will have specific properties. Especially properties such as its tooth configuration and size must effectively cut the workpiece without breaking.

Subsequently, the sizing of scroll saw blades would follow to give you a better understanding.

2.3 Precision and maneuverability

The measure of how easy to use a blade helps to determine whether to go for it or not. For instance, spiral scroll saw blades cut internal curves and round internal shapes because of their shape.

On the other hand, pinned blades cannot do these; instead, they cut only straight and external cut.

2.4 Blade diversity

Scroll blades may either be pinned or pin-less depending on the manufacturer and your choice. However, the pinned blade often sits well on the saw and cuts better because of more stability.

2.5 Lubrication

Similar to other types of blades, scroll saw blades also get heated and blunt. Hence, they also require adequate lubrication periodically to function properly.

With tape or beeswax, you can easily lubricate your blade to prevent it from burning your workpiece, especially wood. Bear in mind that dense wood will quickly dull your scroll saw blades, although proper lubrication can reduce the rate.

Section 3: Do I need pin-end blades or pin-less blades?

Before deciding on the type of scroll saw blade to opt for, you need to understand the two categories available. The pin-end and pin-less blades have peculiar characteristics, which makes them different.

The choice of which type of scroll saw blades to use among these two depends on your scroll saw.

Pin-end or pinned blades have what is known as a cross pin at both ends. They have a holding hook to install on the saw with a cross-piece for this type of blades. You can remove the blade by just unhooking, which releases the tension.

Pin-less or plain-end blades do not have much difference from the pinned counterpart except the mode of installation.

Installing it involves connecting them into the slots located above and below the scroll saw table. This type of blade is fast becoming the most common in modern saws.

Figure 3: Pinned scroll saw blade.

Section 4: Which types of scroll saw blades do we need?

Asides from the blades having different sizes, the teeth configuration plays a major role in its ability to perform a certain task. Therefore, this section focuses on the different teeth configurations of the scroll blades, which divide into seven:

4.1 Standard-tooth blades

Certainly, this class of blades always remains the best seller and most used by all and sundry. Most scroll saws come with a standard-tooth blade from the manufacturer.

Their unique characteristics lie in the equally spaced distance between the tooth. Also, the teeth’ arrangement is one-sided, and that side should face forwards at all times.

Additionally, this class has two sub-categories; the ones used for wood and those for metals. You observe lesser but larger teeth and wider gullets for the wood option to allow for grip and dust evacuation.

On the other hand, the metal option teeth have smaller but more teeth because of metals’ density.

Generally, the standard-tooth blade is multi-purpose but cannot handle complex jobs such as fine detailing and special cuts.

4.2 Skip-tooth blades

The skip-tooth scroll blades look similar to the standard-tooth blade but with one less tooth consecutively. Hence, they have larger gullets or ridges, which makes them similar to the wood type standard-tooth scroll saw blades.

Furthermore, the major merit of this teeth configuration is that there are better clearance and clearer visibility for the user. It is very suitable for beginners to use or practice.

Also, heat dissipation occurs easily, and this prevents smokes or burns when cutting tough materials.

Consequently, it would be best if you understood that the skip-tooth blades are for rough cuts with little or no precision in mind. Thus, never attempt to use them for fine cuts; instead, use them to resize for another scroll blade to finish.

4.3 Double Skip-tooth blades

This blade is similar to the skip-tooth blade but with two teeth placed together along the blade’s length. It implies that it produces a similar cut to the skip-tooth blade but a bit smoother because of more teeth available.

Although, it takes more time to complete a cut than a regular or standard-tooth blade. Endeavor to use this blade to cut only materials with thickness less than or equal to 2 inches.

4.4 Reverse skip-tooth blades

This blade aims to reduce and control chipping, splintering, and cracking of brittle materials. Ordinarily, this type of scroll saw blades look identical to the normal skip-tooth blade.

The only difference is the inversion of a few teeth at the bottom to point in the opposite direction. Again, it experiences faster wear and tear because of its orientation in two directions.

Presently, modern technologies gave room to the development of an ultra-reverse skip-tooth blade. This ultra-version aims to address the issue of dust clearing with a slight altering of the tooth configuration.

Clearing sawdust will help to eliminate heat build-up when cutting.

4.5 Precision-ground blades

Often known as the PGT blade, they can cut tougher materials without getting blunt quickly. They have a similar configuration to a skip-tooth blade but have grounded teeth, not shaped teeth.

For extreme durability, superior strength, and sharper edges, the PGT is the right choice. All you need to do is select the right size for the job you have at hand.

They leave a good finish with minimal chips and cracks. Because of the high level of technicality required, only professionals and experts should handle them.

Finally, they cut faster and efficiently, which helps you increase your overall production.

4.6 Spiral blades

Of all the tooth configuration discussed earlier, the spiral scroll saw blades stand out. It can cut in all directions with its blade having various standard-teeth spun around its length.

Thus, the spiral blade’s teeth appear in all directions, so be careful when installing not to cut yourself.

For all irregular patterns and shapes, you can count on the spiral blade to do it right. On the contrary, they stretch and find it difficult to maneuver tight angles.

4.7 Crown-tooth blades

This tooth blade happens to be the most recent and the biggest innovation in the world of the scroll saw. They feature teeth with a crown-like shape with two points facing opposite directions but similar to the reverse tooth blades.

Unlike other scroll saw blades type, they can cut plywoods, plexiglass, and other harder materials. Generally, when you use this blade, you stand to gain better control for a smoother finish.

Figure 4: Different teeth configuration of scroll blades.

Section 5: How do you choose the right scroll saw blade size?

Sizing scroll saw blades is easy and straightforward, although there is an established number system to this effect. As the blade gets bigger, so does the number system get higher.

The number ranges between #12 and #0. It implies that bigger blades will be thicker and wider with a low TPI.

5.1 As the thickness or density (hardness) of the wood increases, so does the scrolling blade.

Ideally, #5 or #7 scroll saw blades are the most suitable for ¾ inches thick wood. However, the more you skilled you have, the smaller the blade you can adopt for any task. But the rule of thumb is that #9 blade cuts wood of about 1-inch thickness.

5.2 Larger scroll saw blades (#9 and above) are more durable.

Know for a fact that the bigger the blade, the stronger it is and durable. Larger blades in the #9 category upwards have lesser TPI, stays sharper for longer, and do not break easily.

5.3 For thin wood, using a smaller blade is a good choice (3# or smaller blade).

To avoid splintering of wood, materials of about 1/8 inches require #3 or smaller blade type. Blades of this size can cut around tight corners seamlessly. The downside to this class of blade is that they have higher TPI, which cuts slowly.

5.4 Select the blades based on the thickness of the stack if you want to make stack cutting.

Whenever you stack wood or other materials, you have increased the overall thickness of the materials. It means that the blade chosen will correspond to the overall thickness and not the material’s thickness.

5.5 Consider the intricacy of the cuts.

Lastly, the complexity of the cut you have in mind should guide your decision on the blade to use. As discussed above, smaller blades can fit into tight corners even though hardwoods might break them.

The overall conclusion is that you choose the smallest possible blade capable of cutting your material.

Figure 5: Close-up picture of a scroll blade and top clamp/holder.

Section 6: How do we use scroll saw blades correctly?

6.1 Determine which end is the top.

The only way to determine the top-end is via the teeth direction. The top-end should be opposite the direction of the teeth configuration. But this does not work for the crown-tooth blade because it cuts in both directions.

So, you can use any end as the top for the crown-tooth blade. On the other hand, for other blades, run your thumb through to know the exact point and permanently mark your top-end for future reference.

6.2 Prevent blade slippage.

Usually, manufacturers rub some oil on blades to keep it rust-free, but this oil causes slippage. Eventually, you should clean off this oil before using the blade with either sandpaper or cloth.

6.3 Install the blade.

- Fasten the top clamp/holder to the blade.

- Once this is in place, feed the blade to the bottom through a hole on the saw and clamp.

- Check the tension of the blade such that the blade is tight enough so no flex occurs.

6.4 Apply tension.

After installation, tension the blade properly for the best result. You can avoid the blade’s breakage under proper tension since the blade will not get stuck in between the workpiece. Finally, do not under-tight or over-tight; moderate tightness is great.

6.5Prevent friction.

Blades heats up, gets blunt, and eventually breaks sometimes. The sole cause of this occurrence is friction. While it is impossible to eliminate friction, you can minimize its effect by using lubricants such as beeswax.

Section 7: What materials can the scrolling blades cut?

Asides from woods, scroll saw blades can still cut plastic, thin metals, and glass. Nevertheless, cutting these materials with a scroll saw blades involves some peculiarities.

For instance, plastic cutting must do with a lubricated blade because it tends to melt due to friction. Also, glass requires special blades coated with diamonds.

Make provision for instantaneous cooling when cutting to prevent the glass from due to heat.

Figure 6: Intricate pattern cut with a spiral blade.

Summary

To finish with, a strong take-home from this article is the uniqueness of the scroll blades. Furthermore, we have highlighted the scroll blades’ abilities and characteristics, which affect usage and adaptability.

Over the years, NCCuttingtools has developed the capacity to provide cutting tools, saw blades, and customized services. Please send us a message to get answers to all your questions and have all your problems solved.