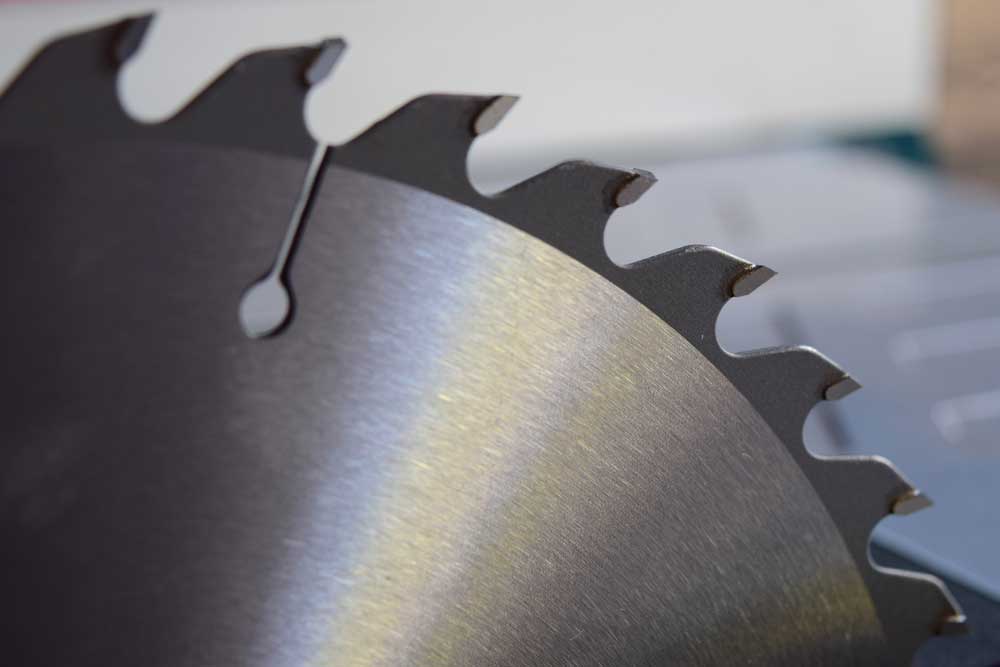

The table saw Blade is the most commonly used saw currently. There are many different saw blades in stores nowadays.

Therefore, you should ensure you have the correct Blade for your table saw to be efficient.

Therefore, we will help you choose the right Blade for your saw. In this article, we have a list of the ten best tables saw blades you should consider.

Please go through it; we are confident these high-quality blades will serve you as you wish.

Table of Contents

- What to Consider When Choosing the Best Table Saw Blade

- Our Top Picks For The 10 Best 10-inch Table Saw Blade.

- 1. DeWALT 10-Inch Miter/Table Saw Blade

- Features

- 2. IRWIN Marples 10-Inch Triple Grind Saw Blade

- Key features

- 3. Makita 10-Inch Micro Polished Saw Blade

- Key features

- 4. Forrest Woodworker II 10-Inch Kerf Saw Blade

- Key features

- 5. Freud 10-Inch Heavy-Duty Rip Blade

- Key features

- 6. Concord Blades 10-Inch

- Key features

- 7. Table Saw Blade–Forrest Duraline 10-Inch

- Key features

- 8. Table Saw Blade–CMT 213.040.10 10-Inch

- Key features

- 9. Table Saw Blade–Oshlun SBNF-100100

- Key features

- 10. Table Saw Blade–Freud Diablo D1080X 10 Inch

- Key features

- How to Sharpen a Table Saw Blade

- Final words

What to Consider When Choosing the Best Table Saw Blade

Table Saw Blade–Basic Blade Types

- Table Saw Blade–Flat Top Grind (FTG)

polishing blades

These are blades with teeth that sit square to the saw plate. Additionally, these types of blades cut through the material like a chisel. Furthermore, flat top grid blades rip the wood perpendicular to the grain.

- Table Saw Blade–Alternate Top Bevel (ATB)

Alternate top bevel blades have each second tooth inclined opposite. These blades are purposely to shear the wood. Therefore, ATB blades are all-purpose.

- Table Saw Blade–Alternate Top Bevel / Raker (ATBR) – ATBR consists of 50 teeth with five. Therefore, these are the best blades to use for crosscutting.

- Triple Chip Grind (TCG) – triple chip grind blade consists of interchanging chamfered teeth cut rough. Additionally, they have raker teeth that clean up the cut. Therefore, this is the best Blade for non-ferrous metals such as aluminum and brass.

Table Saw Blade–Size (diameter)

- Smaller blades

Blades with small diameters cut only specific workpieces. Additionally, they have low RPM speeds.

- Larger blades

Saw blades with large diameters operate fast. Furthermore, they have high RPM speeds and hence work fast. Finally, you can improve cutting depth.

Table Saw Blade–Blade Teeth Configuration

Types of blades of circular saw

- Tooth Count– It depends on the kind of material you are cutting. Therefore, different cuts need blades with different teeth. For instance, a few teeth are best for ripping, while more teeth produce a fine finish. The table below will help you:

| Types of Use | Number of Blade Teeth |

| Ripping wood | 24-30 |

| Crosscutting/sawing plywood | 80-90 |

| Joinery work | 40-50 |

| Artificial and MDF | 60 |

| Plastic laminate | 80 |

Table Saw Blade–Job Type

- Crosscut blade

Circular table saw Blade

They offer specialized cutting.

- Table Saw Blade–Dado blade

Stack of saw blades in a table saw

This is the best Blade to create wide grooves in wood for door panels, drawers, and shelves.

- Table Saw Blade–Combination blades

Mesh circular saw Blade

These are saw blades that use a hybrid approach. They make crosscuts and rip cuts while maintaining a smooth edge.

Table Saw Blade–Blade Coatings

miter saw with a gold blade.

Table saw blades have tungsten carbide coating that reduces heat build-up and increases strength.

Table Saw Blade–Arbor hole size

circular saw Blade.

Arbor hole size is an essential factor when choosing a table saw Blade. Moreover, you use the hole to connect the Blade to the saw’s spindle. Therefore, ensure the connection between the two parts is stable.

Table Saw Blade–Anti-vibration vents.

Table saws have laser-cut stabilizer vents that prevent the Blade from moving from side to side. Additionally, the vents reduce vibration and noise, making it easy to handle the Blade.

Table Saw Blade–Anti-kickback shoulders.

Anti-kickback shoulders are small protrusions behind the cutting teeth. Mostly, anti-kickback shoulders are on rip blades due to the faster ripping rate. Moreover, shoulders minimize kickback.

Our Top Picks For The 10 Best 10-inch Table Saw Blade.

1. DeWALT 10-Inch Miter/Table Saw Blade

DeWALT 10-inch is a high-quality table saw Blade from a manufacturing plant in the United States. Besides, these blades consist of a computer-balanced plate that reduces vibration and noise.

Additionally, the computer-balanced plate improves the finish of the cut.

Features

- Type of cuts: Crosscuts and fine cuts

- Best for cutting MDF, plywood, softwood, Hardwood, molding, and veneer

- Number of teeth: 60

- Teeth shape: ATB

- Arbor size: 5/8″

- Material: Carbide-tipped

- Kerf width: 0.098

- Hook angle: 20°

2. IRWIN Marples 10-Inch Triple Grind Saw Blade

It is the best saw blade to use for acrylic kitchen worktops. IRWIN Marples 10-inch is not smooth like other blades.

Furthermore, it is the ideal Blade to cut Corian, plastic piping, gutters, and ferrous metals.

Additionally, this Blade has 84 carbide teeth. The teeth have a heat-resistant and non-stick coating that prevents gumming while the saw is at work.

Therefore, the Blade is free from sawdust, hence less cleaning.

Key features

- Type of cuts: fine cuts

- Best for cutting: Corian, laminate, acrylic, plastic, non-ferrous metals

- Number of teeth: 84

- Teeth shape: TCG

- Arbor size: 5/8″

- Material: Carbide

- Kerf width: 0.098

- Tooth hook angle: 18°

3. Makita 10-Inch Micro Polished Saw Blade

Are you looking for a saw blade to sort all the woodwork? Makita is the best match for you.

This Blade has ultra-grain carbide teeth. Moreover, you can hone these teeth to 600 grit for a smooth finish.

Therefore, if you need a good finish, this Blade does it.

Additionally, the Blade has a thin kerf that makes it best for low-power table saws. Furthermore, Makita works best on plywood, softwood, and Hardwood.

Key features

- Type of cuts: ripping and crosscuts

- Good for cutting Hardwood, softwood, and plywood

- Number of teeth: 80

- Teeth shape: ATB

- Arbor size:1

- Material: carbide

- Kerf width: 0.097

- Tooth hook angle: 17°

4. Forrest Woodworker II 10-Inch Kerf Saw Blade

Forest Woodworker II 10-inch Kerf saw Blade is the best saw blade for professionals who want the best. Besides, it is an expensive saw blade that may not be affordable to everyone.

Therefore, it produces a smooth finish leaving minimal backside tear out of plywood.

Key features

- Type of cuts: rip cut and crosscutting

- Can cut Hardwood, softwood, and plywood

- Number of teeth: 40

- Teeth shape: ATB

- Arbor size: 5/8″

- Material: C-4 carbide

- Kerf width: 0.125

- Tooth hook angle: 30°

5. Freud 10-Inch Heavy-Duty Rip Blade

Freud’s heavy-duty rip blade has 24 carbide teeth. The teeth leave the stock smooth after the cut. Besides, the Blade has laser-cut vents that reduce vibration and sideways movement.

Also, it has a protective coating that keeps the blade warp to a minimum.

Key features

- Rip-cut and crosscut

- Can cut Plywood, Hardwood, softwood, composites, and laminate

- Number of teeth: 24

- Teeth shape: Dado

- Arbor size: 1″

- Material: carbide blend

- Kerf width: 0.98

- Tooth hook angle: 15°

6. Concord Blades 10-Inch

The Concord saw Blade has 80 teeth, making it the best for hardwood cutting. Additionally, it can cut softwood, abrasive wood, and exotic wood.

Furthermore, it has a thin kerf blade that increases the feed pressure, reducing waste. Also, due to this thin kerf, it does not strain the saw motor.

Key features

- Type of cuts: crosscuts and ripping cuts

- Can cut Hardwood, softwood, exotic wood, and abrasive wood.

- Number of teeth: 80

- Teeth shape: ATB

- Arbor size: 0.98″

- Material: carbide

- Kerf width: 0.89

- Tooth hook angle: 20°

7. Table Saw Blade–Forrest Duraline 10-Inch

The Forrest Duraline table saw Blade has 80 carbide teeth. Moreover, the teeth can last over 300 percent during sharpenings. It also eliminates the urge for two-stage finishing.

Therefore, this is the best saw blade for sheet ply and other large stock.

Key features

- Type of cuts: ripping and crosscuts

- Best for cutting melamine, plywood, oak veneers, birch, and veneers

- Number of teeth: 80

- Teeth shape: ATB

- Arbor size:1″

- Material: carbide

- Kerf width:0.98

- Tooth hook angle: 20°

8. Table Saw Blade–CMT 213.040.10 10-Inch

CMT 213 table saw Blade works best for ripping and crosscutting jobs. Additionally, this product comes with Micro-Grain Carbide teeth that help smooth cuts and last longer.

Finally, it has a non-stick PTFE coating that allows the Blade to run well and is corrosion-free.

Key features

- Type of cuts: ripping and crosscuts

- Good for: plywood, laminate, and chipboard

- Number of teeth:40

- Teeth shape: ATB

- Arbor size:5/8″

- Material: carbide

- Kerf width:0.126

- Tooth hook angle: 18°

9. Table Saw Blade–Oshlun SBNF-100100

The Oshlun SBNF-100100 saw Blade has commercial-grade C-1 carbide.

Therefore, it is extra durable. Moreover, the chipped teeth Grid design offers a perfect finish for cutting bronze, brass, aluminum, or copper.

Additionally, the Blade has a copper-plug extension slot that allows it to expand freely when the temperature rises. Therefore, the Blade does not suffer from heating up.

Key features

- Type of cuts: ripping and crosscuts

- Best for cutting non-ferrous metals

- Number of teeth: 100

- Teeth shape: ATB

- Arbor size:5/8″

- Material: carbide

- Kerf width:0.98”

- Tooth hook angle: 18°

10. Table Saw Blade–Freud Diablo D1080X 10 Inch

Are you looking for a table saw Blade that will last longer, whatever the cutting task is?

Therefore, Diablo D1080x 10 inch is your best match. Meanwhile, this Blade will help you handle hard pieces of materials.

In that case, I advise you to invest in this outstanding product, which you will never regret.

Additionally, this saw blade is less vibrative and does not produce noise during the cutting.

Key features

- Type of cuts: crosscuts and ripping cuts

- Can cut Hardwood, softwood, and abrasive wood.

- Number of teeth: 80

- Teeth shape: Hi-ATB

- Arbor size: 5/8″

- Material: carbide

- Kerf width: 098″

- Tooth hook angle: 15°

Table Saw Blade–How to Change a Table Saw Blade

Cut the Power- switch off the machine and remove the throat plate and plate guard.

Raise the Blade-raise it to its optimum height to make it more effortless when lifting it out.

Loosen the Arbor Nut– pull the wrench with the table saw to loosen the arbor nut and the locking nut.

Swap the Blade-remove the current Blade, swap it for the new one, and then tighten the Blade locking pin and the arbor nut. Also, make a crosscut on a piece of lumber to ensure the Blade sits square.

Table Saw Blade–How to Clean a Table Saw Blade

Table Saw Blade–Tools required:

- Detergent

- Soft wire brush

- Clean water

- A large container

- Paper towels

Examine the Blade- check any stain or sticky resin on the Blade. Nevertheless, this is challenging and may need extra scrubbing before placing the Blade in the water.

2: Submerge the Blade in Water-carefully place the Blade in the water, then add a small amount of the laundry detergent. Swirl the Blade around the dish and leave it for about ten minutes.

3: Use the Brush- scrub the Blade’s surface using the brush to eliminate stains and debris.

4: Dry the Blade- use paper towels to dry the Blade to secure it from rusting. Afterward, let the Blade air-dry for about 30 minutes, then return it to the saw.

How to Sharpen a Table Saw Blade

Materials you need:

- Goggles

- Gloves

- Facemask

- A diamond saw Blade

1, Remove the Dull Blade: remove the dull Blade from your table saws with gloves and a facemask.

2, Fit the Diamond Saw Blades: carefully insert the diamond saw blade into the table saws. Additionally, do not over-tighten the arbor nut since this may buckle the Blade.

3, Offer the Blade up to the Diamond Saw Blade: spin the diamond blade and gently offer up the existing Blade. Moreover, let the diamond grit surface conduct with the dull teeth concisely.

4, Repeat the Process: keep working on the dull Blade until the teeth become sharp.

Final words

As we said at the start of this article, your table saw is as essential as the Blades you use.

Therefore, having the right Blade for your table saw is necessary. So, as you shop for table saw Blades, consider the kind of Blade you require.

Besides, this article relieves you from wasting time trying to find the best Blade for your saw.

To be precise, we are confident that the above information will greatly help you.

Finally, do not hesitate to share this piece with your friends on social media.