One who frequently works with cutting tools has some understanding of drill bits. These bits come in varying sizes and materials. Tungsten drill bits can differ in their material source, from steel to Polycrystalline diamond and Tungsten carbide.

This article intends to shed some light on one of the more common Tungsten Drill Bits. Whether you are refreshing your memory or just starting to use cutting tools, please continue reading to find what you need.

Table of Contents

(Tungsten drill bits)

Benefits of Tungsten Drill Bits

1. They are hard and strong

Before discussing how the characteristic hardness of this tool is an advantage, let’s talk about what makes it strong. Tungsten drill bits are also called tungsten carbide bits.

They possess equal amounts of tungsten and carbide in a matrix of metallic cobalt. This feature quickly makes them one of the hardest metals, making them suitable for various uses.

The Mohs scale ranks 9-9.5, with a hardness value of 1600HV. Steel is just a tenth of that value. For that reason, they are capable of drilling through almost all materials.

It also means they are useful in different sectors, from mining to oil and gas. But we’re still getting to that.

(Tungsten carbide drill bits)

2. They have improved precision when cutting.

In the world of cutting, you can’t underemphasize the value of accuracy and consistency. A unique property of Tungsten carbide drill bits is their precision when cutting.

Their brittleness accounts for this feature. So although when comparing it to steel, they are more durable, they are also more brittle. Thus, making them perfect drill-bit tips.

The term drill-bit tip infers that they are either fixed or brazed at the edge of another material. This other material is often lacking as much strength as Tungsten carbide.

Many precision drill bit designs are tungsten carbide drill bits. They cut this compound into smaller scales with diameters as tiny as 1.5mm to even 0.6mm. Not many materials can be cut that small and still retain the same level of effectiveness.

3. They are durable and long-lasting.

Diamonds are the hardest substance on Earth. On the Mohs scale, they rank at 10, just 0.5 -1 up from Tungsten carbide. This value implies that Tungsten drill bits are pretty tough.

But we’ve already covered that. How exactly does it affect their durability and life span as a whole? Well, their toughness makes them extremely hard to bend out of shape.

They are used in masonry and can drill through virtually the hardest types of stone. They do all that without bending or even retaining a scratch.

Yes, that’s right, they top the board regarding scratch-resistant metals. With that amount of durability, proper care can have your tungsten drill bits in top shape for a long time.

4. They are versatile

Tungsten drill bits are undoubtedly one of the most versatile drill bits in general. They are useful for several things. From drilling through the hardest rocks to crafting 3D models, their diversity is mainly unparalleled.

They even exist in the form of micro drill bits, which are less than a millimeter in diameter. They can be as tiny as 0.2mm when using them in making toy cars and planes.

These drill bits have multiple uses thanks to their versatility. Almost any sector you can think of, from agriculture to mining and construction, requires these drill bits.

Few compounds have applications in such a wide range of industries and sectors. Tungsten carbide drill bits are kind of like the jack of all trades of the drill bit world.

(Tungsten carbide inserts)

5. They are eco-friendly

As you can probably tell by now, tungsten is a significant metal because of its use in drill bits. You could be holding onto some extra cash if you have junk made out of tungsten.

Many products, including tungsten drill bits, come from recycled tungsten. Statistics estimate that as much as 30% of scrap is recycled annually. With the high demand for the metal, it is going to increase in the following years. The fact it is easily recycled is an excellent service to the environment.

Refining this element by either its direct or indirect method helps reduce the cost of raw materials. It also reduces pollution, energy, and valuable land wasted on accommodating scrap.

It’s okay if you entirely believe in the benefits of tungsten drill bits. They are incredibly beneficial and are applicable in many industries, as we’ll see in the next section.

Uses of Tungsten Drill Bits

1. Masonry

As we’ve discussed earlier, tungsten carbide has both the properties of hardness and precision. These are a valuable necessity when working with concrete.

Concrete’s hard and aggregate nature makes it a sturdy material to work in masonry. The carbide bits are essential in working with it.

When you’re working with something like concrete, you need to use something that not only cuts through it. It has to be able to resist wearing out, bending, or even breaking.

Once again, tungsten’s nature comes into play in the form of its durability. These traits make this drill bit invaluable in drilling concrete and bricks. Regular drills might make it through masonry jobs, but they may not do as well.

(Solid tungsten drill bits for masonry)

2. PCB manufacturing

PCB stands for Printed Circuit Board, one of the most common uses of tungsten drill bits. They are an essential part of our electronics and electrical components.

In their manufacturing, a lot of precision is vital as their holes are very tiny. Tungsten drill bits possess improved precision when cutting and find use in projects such as these.

As they maintain their accuracy when cutting down to small sizes, they are notable in making these PCBs.

3. Cutting tools

Cutting tools are prone to face a lot of external forces. Those of temperature and shock include. Due to this inevitable effect of their nature, metals of exceptional resistance and high melting points are a requirement.

This fact is especially true in the mining industry because the cutting tools are under a lot more abrasion. Metals such as tungsten carbide, which can maintain their form under high temperatures, are required. In addition to that, they are also extremely durable and can absorb a lot of shocks.

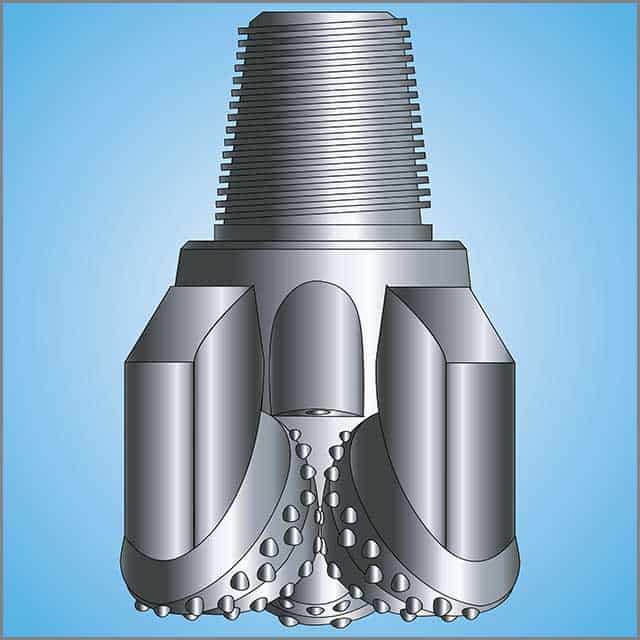

4. Oil and gas industry

In the oil and gas industry, deep drilling into the Earth’s thick crust is a requirement. To get through the hardened ground of the Earth, a hard tool is needed.

Tungsten carbide is one of the planet’s hardest compounds, making it commonly recruited in this endeavor. It is a necessary tool for piercing and forming holes in the ground due to its strength.

This feature makes this drill bit essential in extracting crude oil and other natural materials.

(Tungsten carbide drill bits for oil drilling)

5. Woodworking

Tungsten Carbide drill bits come in varying lengths and diameters. Their size is highly dependent on what you intend to use them for. Industrial sectors such as oil and gas, mining, and drilling require large diameters.

But PCB manufacturing and woodworking need smaller diameters, sometimes even micro diameters. These micro drill bits can be valuable in many hobbies and projects.

Their minute size allows them to possess the necessary precision required for toy making and arts and crafts. They are useful in making model cars, trains, ships, and airplanes.

Conclusion

As you’ve seen, tungsten drill bits are essential in many industries. Their hardness makes them invaluable in drilling in the oil and gas sector.

Their precision makes them highly useful in manufacturing printed circuit boards. In fact, without their durability, masonry might be a much tougher job.

Even cutting tools used in the medical field use this unique compound. These drill bits are versatile and useful in jewelry making, tunneling, agriculture, and forestry.