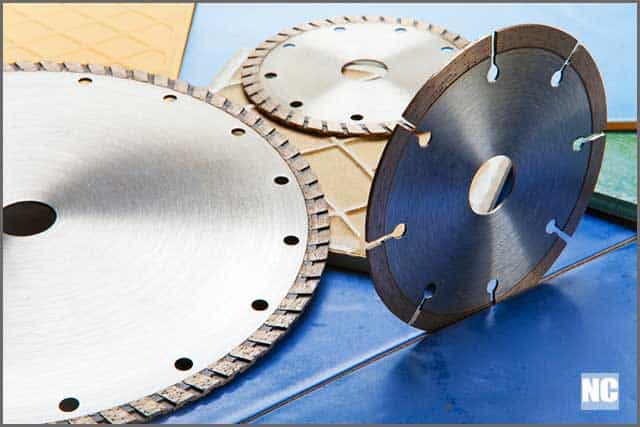

One of the many wonders of the 21st-century diamond wet saw blade is its ability to cut through incredibly hard materials- such as ceramic or porcelain tile, asphalt, concrete, and bricks.

A wet saw approach is employed in cutting ceramic tiles, which requires spraying the blade’s surface with water. However, several guidelines are enumerated in this article’s latter part that requires special attention.

These guidelines remain pertinent to attaining a fine and chip-free ceramic tile cut.

Table of Contents

- 1. Wet Saw–Make Sure the Water is Adequate

- 2. Wet Saw–Adjust the Cutting Depth of The Diamond Blade

- 3. Wet Saw–Use Tape on Top of Tiles

- 4. Wet Saw–Slow use of Diamond Sawblades

- 5. Wet Saw–How to Make Multiple Small Cuts?

- 6. Wet Saw–Observe the Texture of The Tile

- 7. Finding a Balancer

- 8. Always Keep the Diamond Blade Sharp

- 9. Ways to Avoid Edge Notches

- 10. General Safety Precautions

- Summary

Fig 1: Wet saw in action.

1. Wet Saw–Make Sure the Water is Adequate

Using a continuous and sufficient stream of water when using your diamond saw blade for cutting cannot be over-emphasized.

Advantages of using the wet-saw approach include- Rapid reduction in the heat generated from the blade; a Decrease in the dust produced; washing off the debris of the cut material, and further reducing friction.

Generally, having enough water around your tile will also increase the longevity and maintain the cutting efficiency of your diamond blade wet saw.

Fig 2: Sufficient water around Wet saw and tile during cutting.

2. Wet Saw–Adjust the Cutting Depth of The Diamond Blade

Whenever you want to use a wet saw for ceramic floor tiles, adjusting the depth of cut is essential to avoid chipping. Depending on the thickness of the tile you are working with, the extent of the first cut can be decided based on your discretion.

Although, the recommended first cut depth should be at least 1/3 inch into the tile’s thickness, otherwise known as shallow cutting.

Achieving this shallow cut involves different methods. If you use a wet saw with an adjustable diamond blade, then the depth is adjusted at the hinge behind the wet saw.

At the same time, in other models, the platform to place the tile is adjusted and not the saw blade.

To follow this procedure, create a notch at one end, and then a full cut through the tile can be made.

Fig 3: Wet saw with adjustable cutting depth.

3. Wet Saw–Use Tape on Top of Tiles

Attaching tapes around the edges of your tile is important for some reasons:

i. To prevent chips and rough edges.

ii. To keep debris from falling on the tile, causing a blemish.

4. Wet Saw–Slow use of Diamond Sawblades

Diamond saw blades, especially when used for wet cutting, are run at low rpm- this makes sure that the tile does not break because it is a hard and brittle material.

Excessive speed can induce stress in the tiles, making them break or crack. Running the motor of the wet saw blade at low speed will not affect the cut; rather, it depends on if the blade can run at the saw’s speed.

There is a clear difference between the speed of the saw motor and the speed of the blade.

Again, you need to know that the low speed of the diamond saw blade implies a low impact of the diamond around the blade edges, which increases lifespan, keeps your blade in good shape, and helps you save on your running cost.

If you ever want to try running at high rpm, you must use a high-quality blade.

Fig 4: Slow cutting of tile using a wet saw

5. Wet Saw–How to Make Multiple Small Cuts?

Making small cuts on a tile can prove to be tricky and often requires a high level of expertise. Did you know that creating special cuts, such as sharp curves and angles, and making irregular patterns requires uniquely maneuvering the wet saw?

For sharp bends, you need to first mark out the intended shape by creating the initial cut around the boundary of the marked area.

Secondly, you make the final cut of the outer edge and then divide the tile around the curve into small bits, followed by consecutive cuts out one after the other until you get the required shape and outcome.

In all, follow your desired pattern straight before reaching the curve.

Making angular cuts by adjusting the saw blade via the bevel control lever, usually on the left side of the saw blade, most especially the table-top type, is also the best.

Fig 5: Making of multiple small cuts with a Wet saw.

6. Wet Saw–Observe the Texture of The Tile

Usually, the design/shape of textured tiles can be deep or shallow. For deeply textured tiles, a common approach is to create multiple incisions on the marked-out area using the wet saw until you achieve a deep cut.

In other cases, you can turn the tile face down and continue to create deep consecutive cuts/incisions if the texture seems deep and complex.

These highlighted methods help obtain high-quality cutting against a manual tile cutter. Just be sure to purchase a table-top diamond blade saw with adjustable features to fit any possible scenario.

Fig 6: Cutting of deeply textured porcelain tile with Wet saws.

7. Finding a Balancer

A blade balancer checks the quality and location of the diamond saw blade center to ascertain that it is not out of balance. Any form of imbalance in the blade will lead to vibration, which results in a bad, bent, and crooked cut.

An imbalanced blade will produce nothing short of a rough cut, which reduces the quality of the outcome you intend to get. Balancing the blade will bring about straightness in a cut produced by the wet saw.

8. Always Keep the Diamond Blade Sharp

The whole point of the invention of a diamond saw blade is its inherent ability to cut through tough materials with the aid of machined diamond grits around its circumference and teeth.

It will, therefore, be a disadvantage if you fail to keep your blade’s teeth regularly sharpened. Unlike other blades, the roughness of the diamond grit is the primary determinant of the sharpness of the blade.

A sharpened blade would have a rough feel on its edge when touched. If otherwise, then it is blunt.

In sharpening a wet saw blade, you try to remove the already blunt and fine diamond grit on the topmost surface so that you reveal new layers of the diamond grit.

For this purpose, any abrasive material can sharpen your wet saw blade- such as a grinding stone, dressing stick, etc.

Fig 8: New and sharp Diamond blade Wet saw.

9. Ways to Avoid Edge Notches

The presence of jagged edges around your tile can induce an early crack. Smooth edges are critical, especially when your tile will be in a visible area.

Notched edge tiles are undesirable as they give your job a non-appealing look. Although, if the tile is in a corner where grout or baseboard will cover it, you may be good to go.

The number one rule to avoiding a notched/jagged edge is to use the appropriate equipment for the job. For porcelain tile cutting, a wet saw is the best.

Furthermore, you need to ensure that your blade’s teeth are sharpened at all times to avoid a lot of chipping off. Again, you must be fully aware of the diamond blade cutting direction. Failure to cut in the proper direction can lead to chipping and, eventually, a jagged edge.

Fig 9: Cutting a small edge

10. General Safety Precautions

All around the world, safety is considered a top priority and of great concern in any working environment. In operating a wet saw, numerous safety precautions are necessary to watch out for to keep a safe working condition in place.

Highlighted below are such safety precautions:

I. Wear proper safety boots with clothing to protect your feet and other body parts.

ii. Use cut-resistant gloves to prevent accidental cuts, an eye-goggle to prevent dust from entering your eye, and earmuffs to protect the ear from the loud sound of the wet saw.

iii. If your wet tile saw is a rental, then take time to master its operation to avoid an accident.

iv. Wear a respirator over your mouth and nose.

v. Since the working area will be wet, be careful with your movement to avoid slippage.

Summary

With the tips shared above, you should have no problem handling any diamond blade wet saws fit for your small or large-scale tile-cutting jobs. You can read more of our articles for more useful tips and guidance.

At NCCuttingtools, we provide the best diamond saw blades for glass or ceramic tile cutting at affordable and market-competitive prices. Should you need our services, we are available at your fingertips.