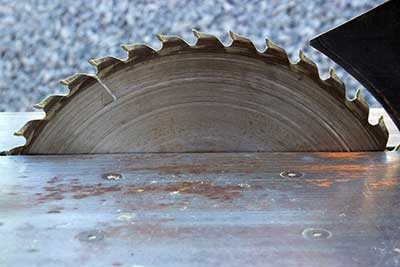

With your table saw, we are expecting you to install a table saw blade with it to carry out your cutting tasks. This table saw blade is capable of handling all your tasks that range from cutting lumber to ripping fancy joints.

Over time, you ever wondered why your table saw blade is doing what it should do. Or it’s the first time you get it; you want to know if it will do what you want. Yes, it cuts, but is it making you experience unnecessary aggravation and stress? If so, you are putting up with wrong woodworking experience, and this is majorly due to the blade you are using.

Indeed, selecting a quality table saw blade amid the various brands there might seem impossible, but it is not as complicated as it looks. Just like life itself, many things have a variety of options, and thus the confusion. So let’s simplify!

Section 1: Importance Of A Quality Table Saw Blade

The table saw to a woodworker seems like the heart of his woodworking place. With this, the table saw blade is the heart of the table saw.

Being an expert, intermediate, beginner in woodworking, you should undoubtedly know that a table saw, no matter how powerful it might seem, it is only as good as its blade. If you work with a ruined or impoverished quality table saw blade, it can make imprecise cuts which would damage whatever project you are working on; a waste of time, energy, and money after all.

With a quality table saw blade, you can make significant cuts even when using a mediocre table saw. A single quality table saw edge gives you the experience of making good rips and crosscuts without the need to replace with a new one regularly.

Section 2:About the Classification of Table Saw Blade

With the multitude of the table saw blades swimming both online and physical stores. You must know the product category you will purchase.

There are four types of table saws, which are commonly designated acronyms. You need to pay attention to these acronyms.

1. Flat Top Grind (FTG)

This category of the table saw blades are also known as “rakers.” Due to their edges which are square to the table saw. They have blade teeth that are similar to those found in chisel on contact with lumber. They are ideal for fast cutting. When you are looking to work on a large number of woods, and you want a blade uniquely designed for ripping, choose this. If put to use for the intended purpose, you will always love your cuts.

2. Alternate Top Bevel (ATB)

This category of the table saw blades have alternately angled teeth. This feature allows you

to shear the wood instead of chopping as you would get with an FTG blade. The steeper the slope, the more shearing action it produces, which directly leads to a cleaner cut. However, the steeper it gets, the more it becomes vulnerable to dulling. Multipurpose is an alternative name since they make you excel both in ripping and cross-cutting.

3. Alternate Top Bevel/Raker (ATBR)

This category of the table saw blades are also known as combination blades. They have 50 teeth arranged in a set of 5. It has the name ATBR because they have 4 ATB teeth with a raker tooth. The concept behind this is that the raker tooth makes the rough cut, and the 4 ATBR teeth clean the wound.

4. Triple Chip Grind (TCG)

This category of the table saw blades have two types of teeth which vary between a raker and a chamfered tooth. In this type of table saw blade, it is the raker tooth that cleans the cut made by the chamfered tooth. TCG table saw modules are efficient in cutting dense materials. The kinds of stuff that would make the ATB blunt instantly.

Don’t mix it up, categories of the table saw blades differ slightly from its types. However, it is essential you understand each of them separately.

Section 3: How to Distinguish Types and Uses of Table Saw Blades

Though they are all known as the table saw blades, they are not made from the same materials nor do the same task effectively. Each module is uniquely made to handle sure cuts, which is why their main difference lies in the type and number of teeth.

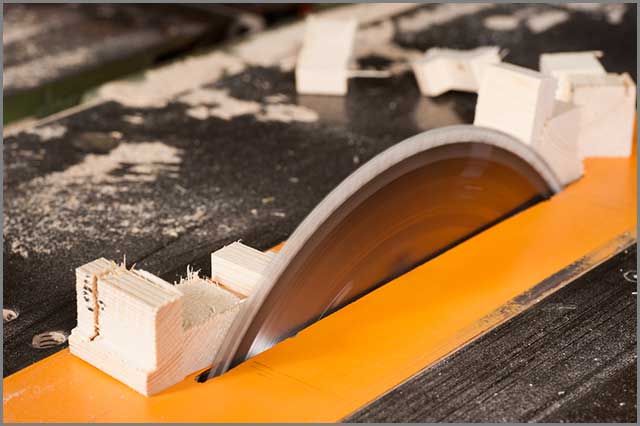

- Ripping Table Saw Blades: Ripping deals with cutting along the grain of a wood/lumber. Thus requiring a lot of material removal. With this particular purpose, this type of blade has a low number of teeth along with a wide gap in between the tooth. Since a lot of material is up for removal, the module is adapted to make fast cuts.

- Crosscutting Table Saw Blades: Cross-cutting deals with cutting across the grain of a wood/lumber. It requires the removal of less material when compared with the ripping blades. With this, this type of table saw leaves have several teeth. The cut is cleaner and precise.

- Combination Table Saw Blades: With this name, you can understand the purpose of this type of table saw blade. Either way, I am going to tell you. As the name implies, they are uniquely made to handle crosscutting and ripping on lumber. Although not sufficient for this purpose. They are quite good. A Jack of all trades but not a master type of deal. They have teeth number that falls between that of the ripping, and crosscutting table saw blade.

- Composite Table Saw Blades: The above examples of the table saw blades primarily cut wood. When cutting other materials, this is the go-to table saw blade. It is a specialty blade.

If you are working on a whole lot of different cuts, you could get several types of blades. If your task is to make simple cuts on lumber, get a ripping blade or crosscutting blade, but if you are on a tight budget, you might consider getting a combination table saw blade.

Section4: Features To Look Out For When Purchasing A Table Saw Blade

The table saw blade is arguably the most critical component of a table saw. Which is why you must be careful when making a purchase/selection. You should be aware of the following.

- Blade Quality: This is important when making a table saw blade purchase. Good blades do not hold back on steel. The inferior quality blade has thin, stamped steel plates. The expansion slot of a table saw blade should not the blunt end.

- Blade Material: The primary material of the table saw blade is steel or carbon steel. These are blades made for cutting woods. Blades for cutting through PC, acrylic materials have teeth made from tungsten carbide or hard metals. It shows they are made to handle/cut different materials.

- Blade RPM: The blade revolutions per second is the maximum speed of the blade. Each blade has a maximum RPM. You should check each table saw blade manufacturers’ RPM recommendation before making a purchase. Doing this will help you pick the right table saw blade for your table saw and prevent the edge from degrading and falling apart during operation, which may cause fatal injuries.

Understanding the table saw blade features allows you to identify its functions and measure its quality. You can’t tell if a blade has three features just by mere looking, consult the blade’s surface packaging for the manufacturer’s blade properties.

Section 5: Social Assessment of Table Saw Blades

If you the type that cut a lot of hardwoods, it is worth purchasing a 24-tooth rip blade to speed up your work and to save wear on your premium all-purpose blade. I wouldn’t pay top dollar so that a dedicated rip blade is going to cut somewhat roughly anyway. That said, you can get a good rip blade for less. – Ricky

When crosscutting lumber and plywood, you’ll probably be happy working with a premium quality 40-tooth all-purpose blade. However, if finance is not an obstacle, get a quality 80-tooth blade for your chop saw and swap it with your table saw when you need to make the best crosscuts or panel cuts possible. – Ryan

If you cut a whole lot of plastic laminate or work with nonferrous metals, stop frolicking and purchase a table saw blade in the TCG category. Your ATB table saw leaves would thank you for not brutalizing them. – Anonymous Tony

I think it all goes back to what you want from your table saw blade, and you can only get the price you pay. Freud does make cheap blades as well as higher-end blades. Where is the difference? It is in the steel and carbide quality. The thinner blades are not the same steel quality and have smaller carbide tips, which mean they are made to use and dispose of, not sharpen or reuse. – Shane Wright

Summary

Selecting a high-end table saw blade is crucial to the functionality of your schedule saw. Making crosscuts on lumber with a RIP-cut table saw module is not on bad for the task, it is like asking for trouble because it would tear the wood and a severe kickback is not out of context.

Cuts from top quality table saw can be sick with cheap quality blades. A right edge is relatively inexpensive and a great investment decision. Why should you settle for fair results when you can have great results?

We sincerely hope our article has taught you some vital information about the table saw blade, using this knowledge, you should be able to select a table saw blade that works well, while not disrupting your budget.

As discussed, the blade is an essential component of the table saw, don’t get careless and buy just any type of module. We would love to hear from you if you have any questions regarding the purchase, samples, and the article. Please feel free to contact us by email.