A couple of years ago, I hosted a couple of friends for dinner at my private residence.

The group consisted mainly of farmers and winemakers, most of whom had inherited the business from their parents just like I did mine. I hinted at one of them John, of my plans to dispose of my old diamond saw machines and he burst into very throaty laughter telling me that there were other uses for my diamond saw blade aside from eliminating them.

He showed me how to make blades from my old blades, a valuable lesson, which I’m about to teach you in this article.

Section 1:Types of Diamond Saw Blade

A diamond saw blade is a compelling piece of equipment, but just like any other power equipment, it cannot be in active use forever. It can last as long as any other service equipment but is also prone to wear and tear and will no longer be of any use in cutting through the hardest substances.

The diamond blade has diamonds fitted on its edge for cutting through solid or harsh substances. You can use a diamond saw blade in numerous capacities, some of which include; cutting through concrete, stones, bricks, asphalt, and many more.

A diamond saw blade is one of the most popular tools in the diamond market, especially in the construction industry as a whole.

There are three essential types of the diamond saw blade, which are the circular saw blade; the diamond gang saw blade and the diamond band saw blade.

Although the circular diamond saw blade is the most widely used type, the diamond gang saw blade and the diamond band saw blade equally enjoy extensive usage among diamond saw suppliers, construction workers, and even for personal consumption.

They enjoy widespread usage as a result of the fact that each diamond saw type design hinges on different custom uses.

Section 2: How to Use Your Old Diamond Saw Blade

It is incredibly easy to fashion out a shiv from your old, and unused diamond saw blade. Blades from a diamond saw are from soft steel as opposed to the general hard steel.

Using soft steel to craft your knife will cut down the whole manufacturing process by two or more steps as you no longer have to file your iron until it’s ready for use in the home.

Making a knife out of your old saw blade helps you to solve a severe recycling problem. Instead of condemning your equipment to the junkyard, you can quickly deploy it to use in other vital endeavors such as carving a knife out of its blades.

There are many different kinds of the knife in the world today, and it is up to you to define the type you’d like to model yours after if at all you desire to.

It is also very possible to customize your knife models that no one has attempted before, as long as you have the skills required to be outstanding.

Section 3: Making blades – the materials you need to prepare

The materials needed to give you a very impressive knife are usually readily available in your immediate surrounding, and it makes it quite easy to fashion a shiv from start to finish with materials from your kitchen or store. Some of these materials include;

● Bench grinder

● Jigsaw

● Multiple clamps

● A garden hose

● Files

● Sandpaper of varying grits

● Chalk or soapstone

● Cold chisel

● Hammer

● Metal plates to use under your work

● Ball-pein hammer

● Duct tape

4-in-hand or a patternmaker’s rasp

The above-listed materials and many more are essential to making a homemade knife from a diamond saw blade.

Section 4: Five Steps – Teach you Step By to Step to Make a Knife

I. Choose a Template

The first step to making your knife is to choose a template you’d like to model it after. In other words, it is vital to have a pattern for the knife you have in mind, whether it’s something someone else has done before or an entirely original idea. although it is usually much easier to use someone else’s template.

II. Cut out the Shape from your Template

The second step to making a knife from your old diamond saw blade is to cut out the shape of your desired knife from the template.

As earlier said, lots of knife models take after other people’s designs, and there’s no crime if your knife also follows this pattern. When you cut out a profile for your knife, you’ll have the luxury of clarity and can move on to the next stage. You can easily trace out the model with a pencil or chalk.

It doesn’t matter if your design is bright or not, as long as it provides a clear picture.

III.File and Grind your Blade to the Desired Shape

The third step is to file and grind your knife to the desired shape. You can do this with an angle or bench grinder.

Since the base material for your new knife is an old diamond saw blade, it becomes necessary to give your blade cut out the essential filing and grinding it requires to work well as a kitchen or industrial knife after cutting out a part of it based on your chosen template.

IV.Work on your Handle

When you have successfully cut out your knife pattern and filed the steel to taste, it becomes vital to work on your knife handle.

The handle is equally as important as the knife itself as making a knife handle also takes as much effort as the knife itself.

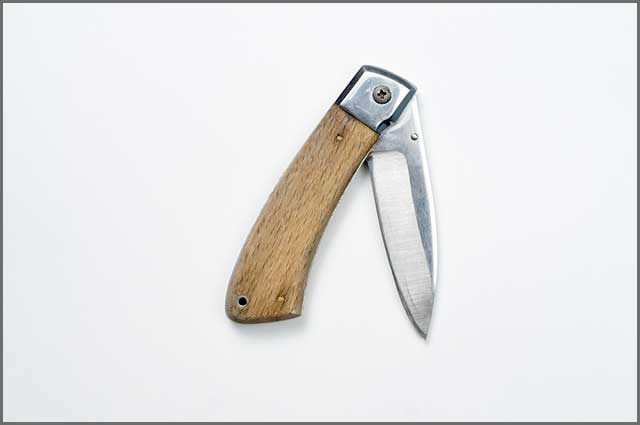

You can make your handle by drilling one or more holes in the base of your knife and then fixing two wooden or ceramic handles held together by a nail. This handle makes your knife more natural to use and, of course, more beautiful.

V.Polish it Till it Glosses

Unknown to many people, this is also one of the most crucial steps to making your knife from an old diamond saw blade. Your knife is never a complete knife without the perfect aesthetics.

It is quite beneficial to polish your knife with a gloss until it shines, primarily if you have used a wooden handle in the fashioning process. It helps to keep wood-eating insects away and also gives your knife the sophisticated look it requires to be of use in the kitchen.

Making a knife out of your old diamond saw blade can be one of the best decisions for your diamond saw machine, but it is nevertheless a simple yet tasking procedure that takes a lot of time and dedication especially if you’re making more than one knife.

Section 5: You should know about the knife you made.

There are numerous ways to finish your knife when you’re making it from a diamond saw blade. These finishes abound as a result of the fact that there are millions of knife models in the world today.

It is, therefore, a necessity to pay as much attention to the finish of your knife as you have put into the making of the blade itself. Your finish determines how beautiful and useful your knife will be; it is the difference between making a random knife and fashioning out a knife for a specific purpose.

A knife finish is what distinguishes between a kitchen knife, a table knife, and an industrial knife. All three can, of course, be crafted from the comfort of your home and still retain as much efficacy as those made by professionals.

Summary:

Making a knife out of your old diamond saw blade can become an exciting pastime for you or a lucrative business, it all depends on your approach to it. However, with this knowledge, you can settle all your recycling problems related to the diamond saw blade.

If you want to buy a diamond saw blade or get more information about diamond saw blades, please visit our website: https://www.nccuttingtools.com/.