Since the advent of saws, the circular saw has stood out as the first choice when cutting metals. Users have attributed this to many reasons, such as portability, ease of handling, and high efficiency. Advancements in technology introduced many other modifications to the design and use of circular saws. For these reasons, we consider it necessary to enlighten you on metal-cutting circular saws. We believe by doing this; then you can get the best out of your circular saw from start to finish.

Table of Contents

- 1. Choose the right saw blade.

- 2. Lubricate the saw blade for protection

- 3. Use appropriate blade depth.

- 4. Be Mindful of the saw and blade’s speed.

- 5. Safely Install the blade on the power saw.

- 6. Secure and Position the workpiece appropriately.

- 7. Observe all safety tips

- Conclusion

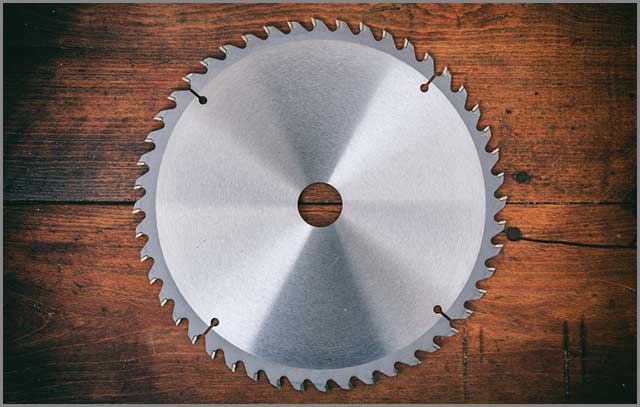

Fig 1: A new circular saw showing a metal blade.

1. Choose the right saw blade.

Metals have various properties, but those prominent for daily needs are mild steel, stainless steel, iron, and aluminum. Therefore, not just any saw blade can be used for cutting these types of metals.

Furthermore, these blades will also vary based on the thickness of the metal, strength, tooth design, the direction of cut, etc.

Blades vary for ferrous and non-ferrous metal cutting. Different grades of metal saw blades cater to a wide range of metals in the market.

HSS metal saw and Carbide-tipped metal blades are today’s two major categories of metal saw blades. Metals such as aluminum are known to be fragile, so cutting them requires special metal saw blades.

Metal saw blades with fewer/ lower teeth cut thicker metals, while thinner metals require blades with more teeth. This means that the saw blades appropriate for cutting iron rods would slightly differ from that of the iron sheet.

It will, in turn, be completely different from that used to cut aluminum sheets or stainless steel. Depending on the thickness of the ferrous or non-ferrous metal as well. Use a metal blade of about 60-100 teeth for non-ferrous metals.

Ferrous metals would require a 30-80 teeth metal blade.

For example, you should consider using ten teeth per inch saw blade for sheet metals less than 1/6 inch thick. For materials up to 1/8-inch thickness, a 12-tooth-per-inch saw blade is perfect.

As the thickness of the metal increase, so should the tooth per inch of the metal saw blade reduce. Even though the carbide-tipped saw blades are more expensive, they make up for it with their exceptional durability.

Carbide-tipped saw blade have up to 10 times stronger than regular steel saw blades. Aside from this, they also give you a smooth and accurate cut.

In simple terms, choosing the right blade is as good as getting the job done already! The right blades should be powerful enough to cut through seamlessly and not get stuck in the workpiece.

Fig.2: Carbide-tipped metal saw blade.

2. Lubricate the saw blade for protection

Knowing fully well that any metal-cutting process generates substantial heat due to friction. This mThis prompts the necessity for a lubricant to reduce heat at the cutting interface.

It is common for metal-cutting circular saw blades to experience overheating if not properly lubricated. Lubrication does a lot of good to ease your cutting task by ensuring the following:

a.Reducing the risk of injury due to blade-grabbing workpieces.

b.Prolong the tips of the carbide-tipped saw blades by helping to dissipate heat.

c.Minimize possible friction between the saw blade and workpiece.

d.It also helps to wash debris off the surface of the workpiece.

You can lubricate using a special metal cutting lubricant, which does not, in any way, attack or harms the metal workpiece. Instead, it makes it luster and gives off a smooth and clean cut.

Finally, with a saw blade wax stick, you can intermittently apply the lubricant along the line of the cut.

Fig.3: Lubrication of metal blade while cutting.

3. Use appropriate blade depth.

The general rule is never to allow your blade to go ¼-inch (6mm) beyond the workpiece thickness. Regardless of your workpiece thickness, the blade must be pre-set ¼-inch plus its thickness.

The design of circular saws with the ability to adjust their blade depth has made them stand out among others.

Remember that you must have initially set the recommended depth before putting on your circular saw. Failure to set the depth to standard can lead to binding, kickbacks, and safety issues.

Generally, blades should barely stick beyond the workpiece thickness and cut more efficiently when properly set this way.

4. Be Mindful of the saw and blade’s speed.

The whole point of being mindful of speed is that you would want to use a blade within the limit of your circular saw. This act helps ensure that your circular saw and metal blade are always kept healthy.

Usually, 5000 revolutions per minute (rpm) at no load is the average speed at which metal can be cut using a circular saw.

Non-Ferrous metals such as aluminum, brass, and copper, the ideal speed is about 3000 to 6000 rpm. Ferrous metals such as pipes cast iron U-channels are cut at speeds of about 1800 to 3500 rpm.

Once you disregard this rule, your blades get overheated, your power circular saw runs idle, or you get badly injured. Often, manufacturers indicate the safe and maximum rpm of blades on their packaging.

Hence, for any combination of blade and saw, the blade’s rpm should remain greater, and the circular saw remains lower. With this, you are sure you cannot exceed the limit and keep working safely on your project.

Another perspective to choosing the right speed is that stability is sure when handling the circular saw at this speed.

Never force the blade through the workpiece; neither should you run too fast through your workpiece. Remember, slow and steady wins the race.

Fig. 4: Close-up image of the metal blade running at high speed.

5. Safely Install the blade on the power saw.

Just like table saws, the metal blades rest upon an arbor. However, due to the nature of the circular saw, one must pay attention to details, as mistakes could cost a fortune.

Unlike the table saw, circular saws could cause more damage if handled carelessly.

Ultimately, ensure all the nuts, bolts, and attachments align in the right place. Your ability to correctly assemble the blade remains pivotal to the success of your job.

You can check out your circular saw’s manual for more information.

6. Secure and Position the workpiece appropriately.

In using the circular saw, there is a need to properly position the workpiece and yourself. Positioning yourself is important as this puts you at absolute ease when working, and you can deliver a good cut. Asides from yourself, the placement of your workpiece is pertinent to the success of your cutting.

There is a dire need to properly secure the workpiece with clamps, vices, or fences as appropriate. Do not ever make the mistake of not doing this before any cutting operation.

Also, you would do yourself a lot of good by keeping to all procedures guiding pre-cutting operations and preparations.

You can keep both hands on the circular saw when cutting by obeying this rule.

7. Observe all safety tips

At all times and situations, safety remains key. Therefore, keeping all safety tips in mind when working is integral. Below are two major tips to ensure you work safely:

a.Watch out for metal chips

Never underestimate the havoc metal chips cause. They are sharp and can cut one’s skin, but they are also pretty hot when cutting is ongoing. In recent times, circular saws have chips collector attached to them.

Only purchase a circular saw that has this essential accessory. Warn bystanders around your work environment to tread carefully.

b.Wear all proper safety gears

For this reason, highlighted above, you need to cover your body properly with gloves and long sleeves. Wear safety glasses or face shields as well as hearing protection.

In your best interest, you must always carry out routine maintenance on your circular saw to keep it in shape. With this, you can avoid disappointment and always stay ready to work.

However, some advise that wearing a glove could do more harm than good. These people believe gloves could get stuck on the teeth during the operation and draw you in.

Fig. 5: Picture showing a man in safety gear while cutting metal.

Conclusion

It’s just not about having a circular saw for metal cutting; it is about using it effectively. We are confident that you have gained a lot. Endeavor always uses the specific circular saw and blade for the right task. In any case, if you find yourself still facing difficulties, do well to watch this video.

NCCuttintools remains positioned to provide you with guidance about appropriate cutting tools to suit your need at pocket-friendly prices.