DIY tasks at home are interesting, from wood cutting to furniture modifications and tiles cutting. Having the skills to do these right is one thing; acquiring the right tools to carry these out is another thing. Circular saw blades are essential tools to have as a regular DIYer. Since they are different types, they can be cut through different materials. These materials include home furniture, roofing, and decking.

They are hardwood, softwood, concrete, plywood, Plexiglas, and more.

You can’t use a single blade to handle tasks involving all these materials. You need at least five circular saw blades that can help you through tasks involving different materials.

So what are the essential five types of circular saw blades you should have?

Table of Contents

- Seven Essential Types of Circular Saw Blades

- 1. Framing Circular Saw Blade:

- 2. Precision Finishing Circular Saw Blade:

- 3. 18 Tooth Circular Saw Blade:

- 4. 24-Tooth Circular Saws:

- 5. Diamond Masonry Circular Saws Blade:

- 6. Ferrous Metal Cutting Circular Saws :

- 7. Compact Circular Saw:

- Conclusion

Seven Essential Types of Circular Saw Blades

As you read earlier, your choice of circular saw blades at home should depend on what you are always working on. Or what you’re most skilled at.

You can have as many circulars saw blades as you desire if money is not the problem. If you are on a budget, this article is for you. It will streamline down the best circular saw blades you can have.

1. Framing Circular Saw Blade:

This is the first choice as it is a utility blade. It serves multiple purposes and is a must-have in your home workshop. With ease, you can use the blade for at least 70% of your work with a circular saw.

It is best put to use when cutting rough framing lumber. It can also handle plywood and sheathing materials relatively easily. The framing circular saw blades are closely similar to ripping cut blades.

They have a relatively low number of teeth, usually 24, which makes the cuts fast and aggressive. It is the blade to use when you prefer speed and volume to precision.

Due to its cutting speed, it has a higher hook angle and a lower kerf number. It allows you to cut through softwood easily. It also comes in different sizes. The sizes are dependent on the type of saw you are using.

2. Precision Finishing Circular Saw Blade:

You will need this blade when you need a circular saw blade in your home workshop to cut hardwood veneer plywood or plastic laminate. You cannot use the frame blade. It is because the precision finishing has more teeth.

It also has a less aggressive tooth angle. It leaves a cleaner cut on the material you are cutting. That is the essence of having this saw blade in your home workshop.

It gives you the ability to have a clean and precise cut. It is usually made with a carbide tip, which confers it with precision. It has about 80 teeth and is suitable for cutting various kinds of wood.

However, it does not cut fast like the framing circular saw blade. It also has a lower hook angle than it. You can also attach it to various saws.

3. 18 Tooth Circular Saw Blade:

This is a perfect circular saw blade when you have a stack of boards to rip. It is because, apart from being able to rip it, it speeds up the job. Ripping means you are cutting with a grain of wood.

The blade is ideal for this particular task because its fewer teeth are angled to rip effectively. The blade has an alternate bevel face tooth grind that gives it additional precision.

It also features a thin kerf, which enables it to make clean cuts and minimizes the strain on the saw.

It has a super-thin kerf, which enables the saw to work less, and an aggressive hook angle on the teeth, which makes it cut with speed. In application, it can cut through various wood and also non-ferrous metals like copper, bronze, etc.

4. 24-Tooth Circular Saws:

This is your best option if you want an upgrade to the 18 Tooth circular saw blade. Due to its thin kerf, it has great versatility and is highly durable. You can attach it to radial arm saws and table saws.

It is the typical choice for tasks that involve ripping soft and hardwoods. Most ideal for materials ¾ to 2 ¾ inches thick.

The good upside to this circular saw blade is that you can sharpen it numerous times to prolong its lifespan due to its large tooth. The gorge between those teeth is also big, allowing it to easily remove chips.

All the features of this blade enable you to enjoy the maximum performance when you use it for the appropriate materials.

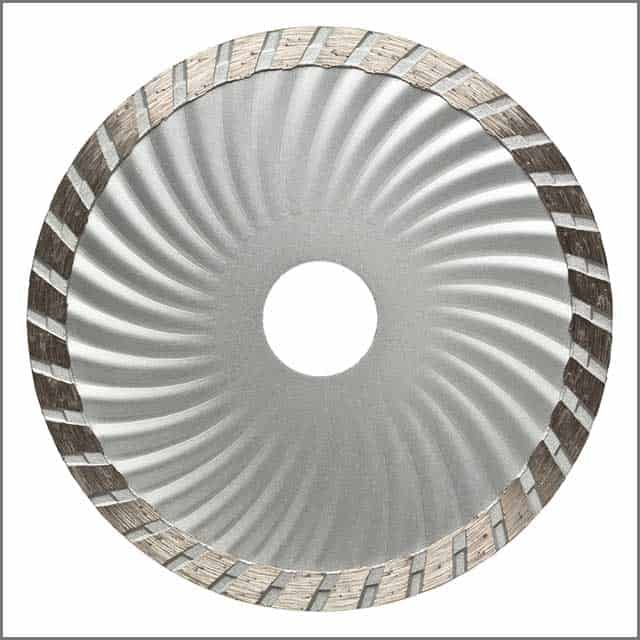

5. Diamond Masonry Circular Saws Blade:

Do you want a circular saw blade in your workshop that can cut concrete, brick, stone, or tile? Then you need a saw like a diamond circular saw blade in your home workshop.

The blade is made out of steel with synthetic diamonds embedded in it. It can cut through various masonry materials. It is what makes it perfectly more than an abrasive wheel.

The Diamond circular saw blades have three major types; continuous rim, turbo rim, and segmented.

The continuous rim blade has no teeth. It is the best use to cut tiles. The turbo rim blade does not have teeth but has more raw cutting power than the continuous rim because it is serrated.

It can cut through bricks and concrete. The segmented type is, however, rimmed with diamond edges. A small gorge separates the edges. It differentiates the segmented type from the remaining two.

The gullet aids the segmented blade in delivering much cutting power but with lesser accuracy and surface finishing.

Some diamond masonry circular saw blades are best suited for wet cutting, while some are for dry cutting.

6. Ferrous Metal Cutting Circular Saws :

A circular saw can handle metal cutting too. The ideal one to buy is the ferrous metal cutting circular saw blade. The ferrous blade has many teeth sloped at a shallow angle for efficient metal cutting and a fine finish.

It has a thin kerf which enables you to achieve a smooth finish with minimal waste.

The low hook angle also aids in the improvement of the surface quality of the cuts. The more teeth per inch of the metal cutting circular saw blade allows it to cut harder, denser materials.

It is the best blade to cut metal in the fastest possible way, and it is more of a reason why you must have it in your home workshop.

7. Compact Circular Saw:

If you have a good circular saw blade, there is no limit to the number of materials you can cut. The compact circular saw blade makes a clean cut with just any material. With 60 teeth, it guarantees quality cutting results when working on thin sheet metals like aluminum.

Due to its versatility, you can cut other materials like plastic and wood. Equipped with a speed of about 10000 revolutions per minute, you can achieve the best cutting results.

This list shows all the important types of circular saw blades you must have in your home workshop. It is to carry out different types of tasks.

The difference between all blades is the number of teeth, teeth design, and the material they are made of. You can buy more saw blades if your budget is not a concern, but this list provides you with the essential ones as a starter considering the budget.

Conclusion

Circular saw blades are numerous, each circular saw blade works on a wide range of materials, but not all are interchangeable. So here is the basis on which we settle on these essential blades. We are always ready to give you the right tools.

As a circular saw blades supplier, we offer quality products, products guide, and friendly and helpful customer service.

At https://www.nccuttingtools.com, we strive to be the highest quality and most affordable supplier of essential circular saw blades.