A metal-cutting circular saw Blade is one of the essential parts of a circular saw.

It is useful for cutting metal materials, and it is the best circular saw blade for cutting aluminum. It is sharp and durable but often managed poorly.

You are often concerned about keeping your circular Blade in the best shape to give it a more extended service life. The best circular saw modules are kept clean, cut accurately, and do not rust.

How do you care for your circular Blade to give it a longer life? After reading this article, you will find the answer.

Table of Contents

- 1. Use Dry-cutting Technology For Your Circular Saw Blade

- 2. Protect your circular Blade by cutting with a lower RPM

- 3. cutting circular saw blade fixed cutting material

- 4. Make Straight Cuts While Using the Circular saw Blade

- 5. Rotate the circular saw blade before cutting

- 6. Best storage method is cutting a circular saw blade

- 7. Never roll metal cutting circular saw blade on the ground

- 8. The circular saw blade needs to be stable

- 9. Use the right circular saw blade for different materials

- Conclusion

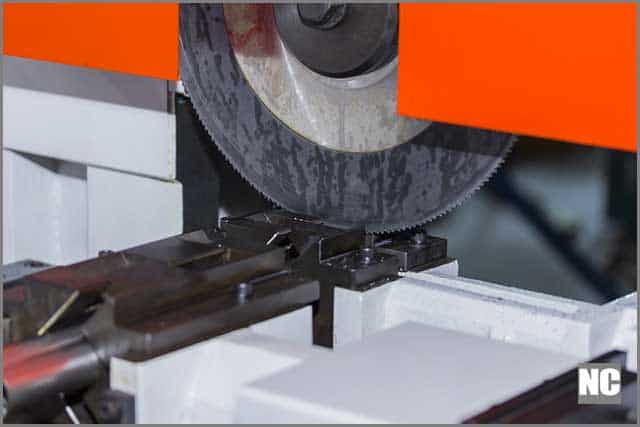

(Close-up Blade of a circular saw on the blurred background)

1. Use Dry-cutting Technology For Your Circular Saw Blade

It is essential to keep your circular Blade dry when it is not in use. The best circular saw Blade is most durable when using dry cutting technology. You do not need lubricants for metal cutting when using the dry-cutting technique.

It is easy for steel to rust; therefore, your circular Blade should be moisture-free when in or not in use. Moisture and humidity will cause it to get rusty and degrade over time. Keep it dry if you’re using an expensive metal-cutting circular saw blade.

When you’re not doing dry cutting, remove the circular Blade from a humid or wet area, on and off the job sites. With this, you can increase the lifespan of your circular Blade and keep it sharp enough for use.

Dry cutting technique and keeping your circular Blade dry when not in use helps to control and reduce corrosion, keeping your metal-cutting circular saw Blade in good, quality condition.

(A circular saw blade for dry-cutting technique)

2. Protect your circular Blade by cutting with a lower RPM

When using your circular saw blade, be careful of your rotation speed because this can ruin or preserve your saw. All modules are designed for use at a particular rotational speed. A metal cutting circular saw Blade should be used safely at a designated number of revolutions per minute (RPM).

It would be best to cut at a lower RPM than required to keep your circular Blade in good condition. It is crucial to ensure that the maximum RPM of the saw attached to your circular Blade is the max RMP on your Blade’s package.

Also, to keep your Blade as the best circular saw for cutting your aluminum materials, know the type of power tool you have. Is it a direct drive or not a direct drive? It would help you identify the correct speed when cutting metal.

(A circular saw blade in a resting state)

3. cutting circular saw blade fixed cutting material

Your Blade remains the best circular saw blade if you follow this tip. You may sometimes not give it a firm grip when making cuts with your sword. It would help if you cut firmly by holding your metal cutting circular saw with a good grip on cutting materials and metal objects.

When cutting with your circular Blade, make sure that you clamp the material securely to the workstation. Set the circular blade depth ¼-inch below the content you are cutting and confirm the bevel angle.

To begin cutting, rest the metal cutting circular saw blade on the edge of the metal material near the cutting line. Please give it a secure grip and then start to decrease. If you cut firmly and have your content adequately secured, it will not rotate.

This cutting method is the correct way to use your circular Blade. It will prevent spoilage of your circular Blade.

(Construction worker cutting metal with metal cutting circular saw blade)

4. Make Straight Cuts While Using the Circular saw Blade

Accurate and straight cuts keep your circular saw blade in the best shape. It is usual for your circular Blade to wander away from the cutting line. It may easily cause the Blade to bind up and get ruined quicker.

There are different types of cuts that you can make with a circular saw blade. A few include rip cuts, cross cuts, miter cuts, and others. Whichever type of cut you make, the best circular saw Blade must and should cut in a straight line.

It would be best if you used a fence to make a straight cut with a metal cutting circular saw Blade. Freehand cuts ruin your circular Blade faster than a cutting guide or wall.

Check out the various ways you can make different types of straight cuts using your circular Blade, and be sure to use any of the techniques when using your module to protect the saw blade.

(Making freehand cuts with metal cutting circular saw blade)

5. Rotate the circular saw blade before cutting

Before you use your best cutting circular saw blade for aluminum to cut into the material, ensure that you rotate it first. Give it a spin before you connect it to aluminum or other metal materials to see if it is in the best condition for cutting.

Rotate the circular saw blade to preserve the service life and safety and preventive measures. Proper blade rotation helps keep the cutting-edge performance at maximum level and extends blade life.

You may research the proper way to achieve this, to give your metal cutting circular saw blade

the attention they need.

(A spinning circular saw Blade)

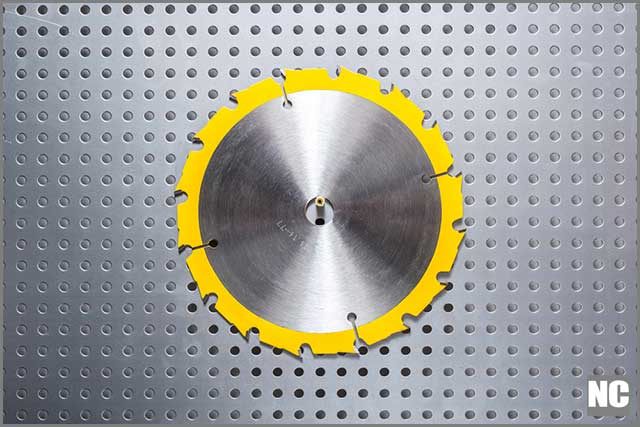

6. Best storage method is cutting a circular saw blade

Do not save your circular Blade on the bare ground or in poor storage condition. After you have used your circular saw blade and are ready to store it, you would need to keep it in either a plastic knife holder or a wooden one.

Ensure that any storage spaces are clean and dry before storing them to avoid rust or corrosion. If you must store it outside of these storage areas, do not allow the Blade’s kerf to rest on the ground, but rather hang the edge through the hole in the center.

Fix a screw or nail on the wall, and insert the circular Blade into these hangers using their center hole. If the module is placed on a shelf or floor, it may wear out and become dull.

(An alternative for storing your metal cutting circular saw blade)

7. Never roll metal cutting circular saw blade on the ground

A few things would happen when you roll your metal cutting circular saw blade on the ground. Firstly, you ruin the teeth of a perfectly functional circular blade.

Your Blade saw was not meant to reduce the floor materials, so keep it off it.

Another thing that would happen is that your circular Blade becomes hot due to friction, which could damage your circular saw blade. The circular Blade of your metal cutting saw may become too hot and ruined from poor use.

(A circular saw blade laying on the ground)

8. The circular saw blade needs to be stable

It would be best to make the Blade stable to avoid resonance when using a circular saw blade. Stability in metal cutting circular saw blades is essential also to keep and ensure longer service life.

You may be wondering how you can keep your circular saw blades stable. One right way is to buy a circular saw blade that is the right fit for your metal cutting circular saw. If you install the perfect fit, it will stay in place and not move about during cutting. It also reduces misalignment in your Blade to ensure precision cutting.

Another way to keep your circular blade stable is by getting a stabilizer. It provides stability when cutting with blades that have a lesser width.

(A durable metal cutting circular saw Blade at work)

9. Use the right circular saw blade for different materials

For different hardness, density, and thickness properties of equipment, you may want to use the best circular saw Blade fit for that purpose. It should be a circular blade with suitable blade spacing.

Ensure that you use the right metal cutting circular saw blade. Many circular saw blades are often said to be suitable for all types of materials, but the truth is that every metal material has a different edge.

Don’t use a fine-tooth blade to cut laminate; don’t use a standard carbide blade to cut steel. Know the right circular Blade for the job, and make use of that. It would give your knife a longer life span.

Conclusion

If you’re reading this, it means you care about your working tools and how to take care of them. In this article, you will find nine tips to help you own the best circular saw Blade for cutting aluminum and other metal materials.

Keep your circular Blade dry, store it properly, use the right modules for the jobs, and give it overall proper care.

If you encounter any challenges or require similar services to help keep your work tools in perfect condition, you may call NCCuttingtools. A dependable facility with a wealth of experience in this field.

We are undoubtedly qualified to assist you better.