Drilling your wood core drill bit can be tricky, and sometimes having the right drill bit will help you drill better. Most users are often faced with the challenge of knowing the perfect wood core drill bit for their project. On that note, this article will highlight and discuss six different tips that you should look out for before choosing your wood core drill bit.

Table of Contents

- 1. Choose the right Drill Bit Material.

- 2. Core Design

- 3. Drill Bit Point Coatings

- 4. Type of Project

- 5. Drill Bit Point Geometry

- 6. Cost

- Summary

Figure 1: Drilling a wood core

1. Choose the right Drill Bit Material.

Now, wood core drill bits vary in shape, point lengths, and material type. The drill bit material type ranks as a top factor when choosing your wood core drill bit.

This is because different material types have unique properties that distinguish them from others. Hitherto, most users often prefer bits with materials that will produce effective drilling. That said, there are various types of drill bit material, namely;

Steel Bits are very suitable for cutting softwood core and are cheap. However, they are fragile and tend to break. They also become blunt quickly, which inadvertently gives them a short service life.

Titanium Coated Bits: this bit material is the strongest of them all. With the capacity to retain sharpness for extended periods, they are also very tough and can cut hardwood core easily.

Their only offset is that they are pricey, costing as much as double some other materials.

High-Speed Steel: This material is an improvement from the steel bit. This steel type undergoes different treatment procedures, allowing the drill bit to last longer, stay harder, and retain sharpness.

On a side note, they are more expensive than steel bits.

Black Oxide Coated HSS Bits: again, this is an improvement on the HSS. The black oxide coat gives the bit a longer life span and a higher resistance to wear.

Figure 2: Different drills bits with different materials

2. Core Design

Drilling through wood with a drill is a practice that spans hundreds of years. A product of that evolution today are different types of drill bits that serve different specific purposes.

Most wood core drill bits have pointed tips and spurs on their sides. The various types of wood core drill bits with their different applications are as follows:

Diamond Core Drill Bits: this drill bit has a pronounced spur, which makes them very accurate, easy to locate, and maintain on a single course. These features make them the best suitable when considering undertaking precision drilling projects.

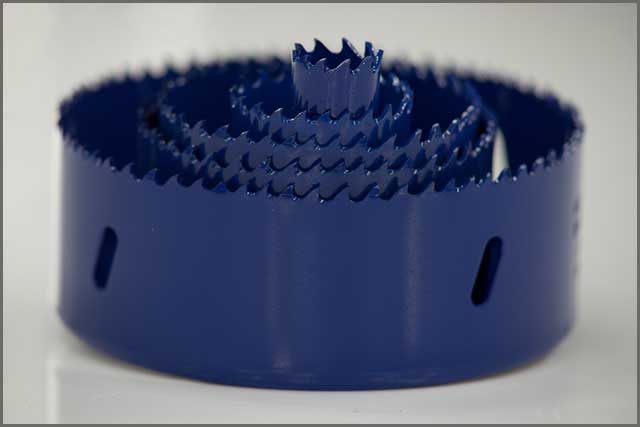

Bi-metal Hole Drill Bits: with a saw-like point, they are the perfect drill bit for cutting wood core quickly and roughly. Their saw-like point makes them less accurate in comparison.

Taper Carbide Drill Bit: this bit is more common among professionals, as they are best suited to drill into heavy-duty wood. This bit possesses hex, of which its shank helps the drill grip materials faster. The structural design of this bit provides it with a longer service life.

HSS Core Drill Bit: This is one of the most popular wood core bits and a must-have. Manufacturers design this bit with treated Steel, making it harder and more resistant to heat. These unique properties enable them to cut at high speeds without concern of overheating.

Figure 3: Set Crown for the wood core

3. Drill Bit Point Coatings

Most wood core drill bits point to come in different coatings that seek to improve their cutting performance. A vital edge that some wood core drill bit has over the other is the material of the bit.

More so, you must select the drill with the best coating to help achieve the optimal performance of the drill bit.

There are a few drill coating present today, some of which are;

Black Oxide Coating: this type of coating is famous among core drill bit manufacturers. Because it helps to increase chip flow making drilling smoother and faster. This coating is also suitable for reducing friction.

Titanium Nitride Coating: this coating is usually gold in color. Wood core drill bits with point coating usually drill through the core faster. This coating also increases the service life of the drill bit.

Titanium Carbon Nitride Coating: this coating increases the point’s hardness. It makes the drill bit cut through harder wood core composites.

4. Type of Project

Another essential factor to consider before choosing your wood core drill bit is your project type. Wood cores are a composite material, and for this reason, they contain different cellular structures for different designs.

There are several factors to consider when considering the type of project.

Type of wood core: most users use either the Cedar Wood core or the Balsa Wood Core. The cedar wood core has composite skin on both sides. This wood core has its grain parallel to its laminate faces.

They also contain cedar fibers spanning the entire core, giving the cedar wood core a rigid frame. So if you want to undergo projects with this type of wood core, you should opt for drill bits with shorter but point lengths.

On the other hand, the balsa wood core is a compact wood with high compressive strengths. The balsa wood can drill with simpler wood core drill bits like the spade drill bit.

Type of cut: different projects require various types of drilling. You can choose the auger drill bit if you aim to achieve faster and neater drilling in softer wood cores.

If you are looking to drill through harder wood core faster without much regard for precision, you can opt for the spade drill bit.

All these are just a few of the types of cuts you can need; the crux remains that once you know the type of cut your project needs, you can choose your drill bit.

Figure 4: Set of Core Drill bit

5. Drill Bit Point Geometry

The Drill Bit point is another point to consider, as different drill bit has different point lengths. These point lengths are crucial because they characterize the cutting efficiency of the drill bit.

A good example is the diamond core drill bit, which has more blunt points than your auger drill bit. The diamond core bit is longer, permitting more open channels for the coolant to reach the cutting area in the hole.

Other criteria, such as the wood puckering and chip breaking properties, are a function of the drill bit point geometry. It would be best if you also opted for point lengths with better torque properties to cut deeper holes.

Figure 5: Core Point for a bit

6. Cost

Wood core drill bits are of different types and different qualities. You must understand that you must evaluate the cost efficiency of your drill bit. Choosing the perfect drill bit will entail both cost and performance efficiency.

Drill bit cost is quite important, with drill bits of expensive composition like the diamond core costing far more than the normal bi-metal drill bits.

Due to this significant price difference, you must choose the drill bit that economically justifies its performance. Occasionally, this performance justification is accomplished by staying in the hole longer.

In such cases, the benefits of using it are intangible.

Summary

The wood core drill bit is a cutting tool popular among professional, skilled, and unskilled users. The wood core comprises a composite material that can be quite difficult to cut. This article provides you with different tips on how to choose your wood core drill bit.

So, as you continue looking for a better understanding of choosing the best diamond drill bit for your project, look no further; NCCuttingtools has got you covered.