All around the world, safety is one of the most important things to watch out for. The diamond saw blades are the revolutionaries of the construction business. And as all revolutionaries go, they have to be handled with the most care.

Most accidents have occurred due to negligence and lack of safety precautions when handling the diamond saw blades for operation. We aim to prevent this, so we have tips for you on the safe use of diamond saw blades.

Check out this YouTube video.

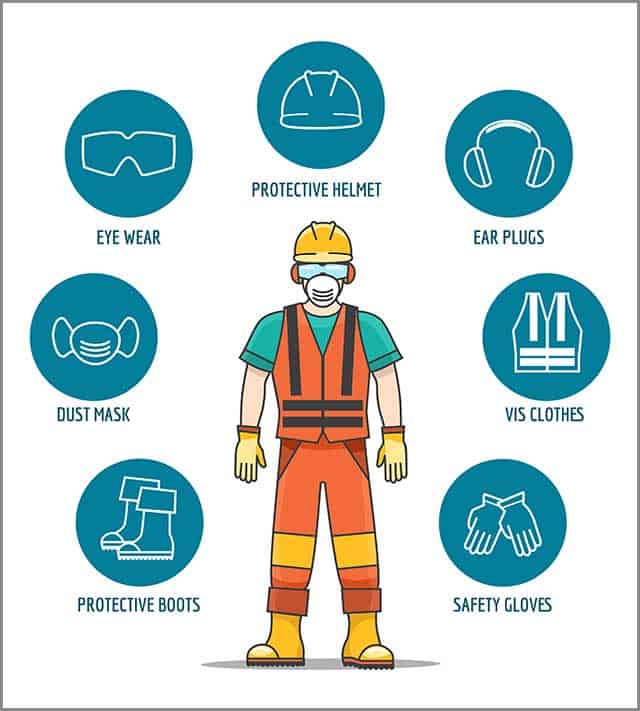

Section1: Personal protection, you should pay particular attention to

Prevention is better than cure, that’s why you should always use protective gear each time you’re operating with the diamond saw blade. And here are some of the safety tips to follow while using the diamond saw blade.

- It is a fact that 230 people develop cancer each year after they’ve been repeatedly exposed to silica. Silica is a highly carcinogenic substance produced when diamond blades are used on surfaces like clay, tile, stone, and concrete.

- To avoid inhaling this harmful substance, it is highly recommended that you use a face mask or protective respiratory gear whenever you’re cutting with the blades.

- You could also use a wet-cutting system to control the spread of the silica.

- Eyes also get blinded if sharp shards of the materials are cut to get into them, and for that, the proper use of safety goggles or a face shield is highly recommended for use here.

- Prolonged exposure to the noise created by the cutting will effect in long-term damage to the ear and has been known to cause partial or full deafness in some cases. Therefore, it is highly recommended for your safety to use earplugs and defenders.

- Wear low flammable snug fitting clothing with cut-retardant pads when you’re operating the diamond saw blades for cutting, This prevents fire outbreaks as well as avoids the trapping of apparel in the moving parts of the machine.

- Wear steel-capped non-slip work boots to give you that added footing you need when cutting.

Section 2: You Need to understand the difference between diamond saw blades

However, the usage of Diamond saw blades sometimes requires you to use different diamond blades for different cutting.

Not all blades are the same, and this is because we have different binders, different types of cutting, and different kinds of materials to cut. The two significant types of cutting are dry cutting and wet cutting.

Therefore the styles of the cutting of the diamond blades are the difference we’re focusing on. There are three different styles of a blade; the segmented rim blade, the continuous rim blade, and the turbo rim blade.

Let’s take them one after the other.

2.1Continuous Rim Blade

Commonly referred to as a blade for wet cutting. It is used for cutting porcelain tiles, marble, ceramic tiles, and granite. It produces the best cut-out of all the styles of blades but is also the slowest of the styles. Using water when cutting with a wet-cut blade helps the blade’s longevity.

The water cools down the blade from heating; it also decreases the friction in the cutting zone by flushing out all the debris of the materials cut; it also reduces the dust produced from the cutting. If you’re looking for a slow and steady blade for cutting, the continuous rim blade is your blade.

2.2Segmented Rim Blade

This blade is known for giving the roughest cut and is quite famous for all the dry cuts because of the segments at the edges of the blade.

These edges allow for the flow of air and for cooling the blade core from overheating. It is used on hard and dry surfaces like concretes, blocks, hard reinforced concretes, bricks, limestone, and masonry.

If you’re interested in a sharp and powerful cutting blade for your hard materials, the segmented rim blade is your blade.

2.3Tubo Rim Blade

This blade is used for both applications; wet and dry. It is equipped with smaller segments at its edges to allow for cooling off the module; it is also integrated with an interwoven diamond matrix.

The blade also has small holes randomly placed around the modules; this is to help increase the blade’s cooling capacity. Useful for cuts on concrete, limestone, and brick materials the blade is the fastest due to its fantastic design.

Notwithstanding, since you know the different types of diamond blades, it is also essential you know how to use the right edges.

Section 3: Choose the right blade for your job

As of now, there isn’t one blade that cuts all material. Therefore, you need to choose the right knife for the right equipment when you have wet and dry cutting.

The first thing to do is to learn the four essential blade components; this will help you to choose a blade with the correct features for the cutting you need. These include;

- Weld: This is what attaches the cutting segments to the core of the blade.

2. Base: This is an engineered to precision steel disk accompanied by a segmented rim that holds the diamonds.

3. Diamond Crystals: Not the diamonds on rings, these diamond crystals are what slice through the materials due to their sharp cutting edges.

4. Matrix: This is the metal band that holds the diamond particles until they wear off.

All these components work together in perfect synchrony, the diamond crystals do the cutting, and as they become duller, the matrix sheds away to release the old diamonds and reveal newer sharper ones that were embedded in the pattern.

The bond which is the matrix is inversely related to the cutting it makes; if the blade is used to cut a soft material, the bond should be hard, and if the blade is used to cut hard materials, the bond should be sweet. This is to allow easy erosion of the bond to reveal sharper diamonds for use.

The next thing after the basics is to know what you’re cutting. Matching the blade to the materials you’re cutting will increase cutting speed as well as blade life. The features of this are the compressive strength, type of and the size and hardness of the aggregate.

Ensure that the speed of the blade does not exceed the maximum RPM. Then ensure that the blades are not inserted wrongly, but are kept in the right direction for use.

Choose between wet and dry cutting, don’t use s wet cutting blade for a dry surface and vice versa.

However, before you use these blades, it is essential you check if they are in good working conditions to prevent the hazard.

Section 4: Different recommendations for wet and dry cutting

This is a bleed-off of the right use of diamond blades, but our main focus is on the cutting styles.

Dry cutting and wet cutting are mainly different from their weld. Dry cutting blades are fitted with segment welds to resist heat, and for that, they do not need water for cooling. Wet cutting blades are used for cutting joints, and since they need water for cooling, they make a deeper cut.

- A wet cutting blade should never be used without water.

- You can make a long continuous cut with a wet diamond blade, never do such with a dry cutting blade, it should be allowed to cool down to avoid heating.

- Never force the blades into materials, forcing them will just cause more damage and heating to the blade.

- Don’t cut dry with a wet blade; don’t mow wet with a dull knife.

- Always follow the manufacturer’s recommendations.

- Always inspect.

While all these are important, it is also advised you ensure a good maintenance routine.

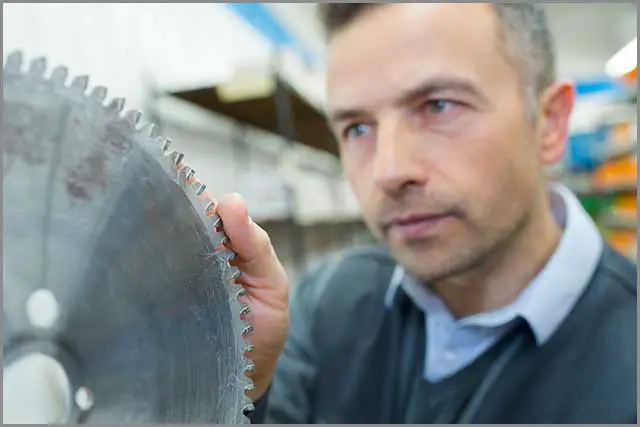

Section 5: When you are ready to cut, you need to do the inspection

This is very important as safety will be guaranteed, and lots of danger could be prevented if all blades are first inspected before being put to use. Make sure that the following are checked before every use:

Cracks: Make sure that there are no cracks between the blades.

Missing Segments: It will make your work slow and constitute a work hazard.

Wear and Tear: Checking for wear and tear in the blades before cutting reduces the amount of danger that will occur.

Blade damages: Any damage to the blade will be damage to you.

The inspection of all these before use will ensure that you come to little or no harm at all.

Section 6: Need to pay attention to the inspection and maintenance of the saw blade

Maintenance culture sometimes is all that is needed for the blade to last longer. Below are some tips for maintaining your diamond saw blades.

- If there’s a segmented loss due to worn bearings, worn blade flanges, or hard blades which makes it hard for materials to cut, you should switch to a softer bond, replaces the blade flanges, and replace the work bearings.

- If the blades overheat, check the water supposed and the obstructions in the water system, and try to use them only for shallow cuttings not long continuous cuttings.

- If there are cracked cores due to excessive cutting pressure or overheating, change the blades used and use adequate cooling techniques.

Diamond saw blades are the trusted blades for effective cutting of any materials; they help give a powerful, seamless cut on any documents.

As stated earlier, diamond saw blades are highly technical powerful machinery, and that should be handled with expert care. The safe use of these machines will reduce the danger associated with the user.

While operating, make sure you’re wearing the appropriate PPE, use the right blades, inspect before every use and take proper maintenance of the modules to ensure the lifespan of the leaves as well as their efficiency.

Section 7: Summary:

After reading this article, you should have some understanding of the safe use of diamond saw blades, This is not only responsible for ourselves, but also for society.

There are also specifications for diamond saw blades on our products. To be strictly enforced. If you would like more information on diamond saw blades, you can click on our website. We will provide you with a comprehensive service.