Diamond saw blades are extremely versatile pieces that can help to expand the range of cutting applications significantly. However, if you want the most out of your blade, it is important to pick one that meets your expectations.

Choosing a diamond blade is not an easy task. That is why we prepared a guide that will tell you everything you need to know about these tools. By the end of the article, you will know how to pick a diamond blade and use it the right way.

1. What Are the Main Components of Diamond Blades?

If you grab and observe a diamond blade, you will find that it has four components:

- Diamond crystals – although they have the name diamond in them, these crystals are primarily synthetic. You will rarely find a natural version because of the price. The reason for using diamond crystals is that it is easy to adjust the desired size and shape. The fact that the manufacturers can design synthetic crystals allows adjusting them to particular applications.

- Metal bond – you will find that the metal bond holds the diamond crystals in their position. It is a mix of different metals that might affect the exposure rate of the crystals. If you go with a soft bond, you will enhance diamond erosion, which makes this option suitable for cured concrete, granite, and other hard materials. On the other hand, there won’t be as much erosion with a hard metal bond, and that option is suitable for asphalt, green concrete, and applications that are softer than the ones mentioned above.

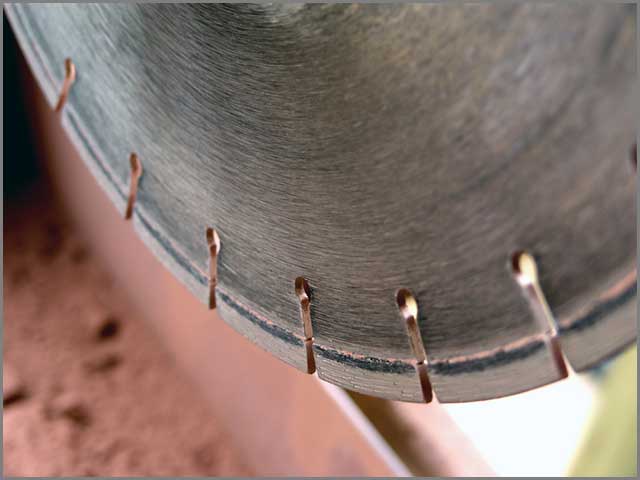

- Diamond edge – after shaping and heating the metal bond and crystals, the manufacturer attaches them to the core of the blade. The edge of the core might have serrated, continuous, and segmented rim configuration. You should choose them based on the desired application. Regardless of your choice, the edge should be wider than the core to ensure the optimal function of the blade.

- Steel core – the core itself usually made of steel that treated with heat. You will also notice the tension that secures a proper blade turning course on the arbor hole positioned in the component. The core has the task of reducing stress and optimizing performance, especially when cutting dense materials.

2. How Does a Diamond Saw Blade Work?

If you used standard metal saw blades, you might be surprised with their diamond alternatives. These blades of different work, because there is no actual cutting. Although everyone uses that term, these blades grind the material.

Have you ever seen a diamond blade? You could easily explain its construction – a core that has diamond particles around it, and something that keeps everything in place. The specifics of this blade lie in the diamond particles. They can scratch things, and that is the characteristic you utilize when using them.

Imagine that you need to cut a stone piece. As you do the “cutting” with a diamond blade, each of the diamond components spins and scratches the material. Since the blade is capable of making a huge number of rotations per second, that results in millions of scratches that make the tool go through the stone ultimately. Thanks to that “scratching,” you split a single stone piece. However, you didn’t do any actual cutting. Instead, you used diamond particles to grind through the material.

And here is another great piece of news – not all diamond blades have sharp teeth. That decreases the risk of cutting yourself during the process, but you still need to be careful when using these components.

As you can see, the working process of a diamond saw blade is simple. Despite that, the product is very versatile, and you can use it on a wide variety of applications.

3. What Do Diamond Saw Blades Cut?

Diamond saw blades take the versatility of a cutting blade to an entirely new level. They are incredibly capable of cutting various applications. However, their primary focus is on materials that are particularly hard and think.

You know that standard saw blades are capable of cutting plastic, wood, and even metal. But what if they come across concrete or marble? The chances are these blades would break if you try to cut extremely hard applications. That is why diamond units designed as a substitute that can handle exceptional material hardness. It is what justifies the higher price of diamond saw blades compared to other types.

Diamonds to be among the hardest materials out there, which is why it can “scratch” any other material. That is what makes it suitable for an extensive range of applications.

Here are only some materials that diamond blades can cut:

- Marble

- Concrete, including reinforced concrete

- Stones like slate and granite

- Ceramic and porcelain

- Glass

You can also cut brick, pavers and tiles made of the materials mentioned above, and any other hard applications. If you stand a chance against a material that has exceptional hardness, it will be with a diamond saw blade.

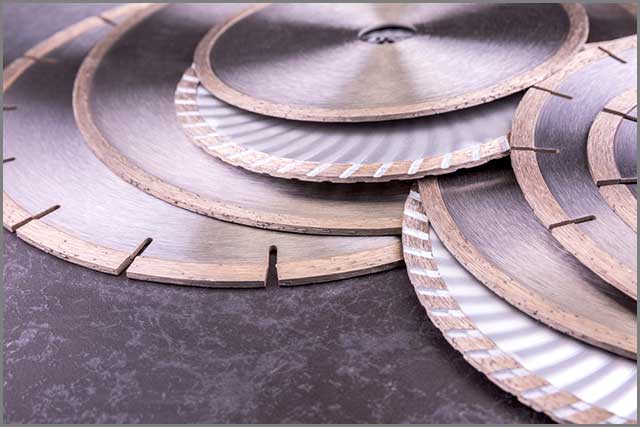

The cutting potential of a blade will depend on the rim you choose. We already mentioned that you could choose between three available rims, and these are their specifics:

- Segmented rim – if you can’t use water or another coolant, consider using a segmented rim as it has impressive resistance to overheating. These blades should have at least ten, and usually no more than 14 segments. A deep grove is noticeable between the sections, which are present to improve heat dissipation. You can use these blades on bricks and concrete, but don’t hope to get a particularly clean cut. Avoid using segmented rim on tile, or you might ruin the material.

- Turbo rim – although you will notice the difference in appearance compared to the segmented rim, the truth is that these two blades are quite similar. You will also find sections and holes that improve heat dissipation. However, turbo rim is suitable for both dry and wet cutting. The sections remind of a turbofan, and air going over the blade is what keeps the blade cool. You can use a turbo rim for limestone, brick, and concrete. It is capable of making clean cuts.

- Continuous rim – this type of blade is suitable for wet cutting. Since it doesn’t have admirable heat dissipation, you should use a coolant when working with a continuous rim. You will recognize these blades for their flatness. It can deliver a clean cut and is versatile and capable of cutting ceramic, porcelain, granite, marble, etc. It is worth noting that this is not the fastest type of diamond saw blade out there.

4. Pick Between Wet and Dry Cutting

As the name suggests, wet cutting will require using water as part of the cooling process. That might make dry cutting a logical option since it won’t leave any mess behind. Additionally, you do not have to consider water supply, which eliminates the need for using hoses and tanks. If it is imperative to keep the application and working space dry, this cutting type is the most suitable option. However, that doesn’t mean dry cutting is always the best choice.

As the name suggests, wet cutting will require using water as part of the cooling process. That might make dry cutting a logical option since it won’t leave any mess behind. Additionally, you do not have to consider water supply, which eliminates the need for using hoses and tanks. If it is imperative to keep the application and working space dry, this cutting type is the most suitable option. However, that doesn’t mean dry cutting is always the best choice.

If you expect high heat during the cutting process, using water to decrease the heat is imperative to avoid sparks and other issues. Additionally, you will reduce dust and other waste from compromising your work, and the cleaning process should be easier. The problem is that you will have to go outside for wet cutting as it is unsuitable for indoors.

Dry cutting might be a better choice if you are looking for a clean and crisp cut, such as a decorative concrete pattern. As for wet cutting, you can use it for deeper cuts, but here is one thing to note. Never use a wet blade for a dry cutting process, although you might use a dry blade for wet cutting.

5. How to Maximize the Lifespan of a Diamond Saw Blade

Diamond blades are pricier than their standard counterparts. But regardless of the cost, you want to make the most out of every tool you have. Maintenance is important to maximize the longevity of your diamond saw blade.

Diamond blades are pricier than their standard counterparts. But regardless of the cost, you want to make the most out of every tool you have. Maintenance is important to maximize the longevity of your diamond saw blade.

Here are some tips to consider to improve the lifespan of your unit:

- Check your equipment before using it – Make sure that everything is connected correctly is very important before you start using a diamond saw blade. The blade should not have any damages or cracks, and you should also inspect its sharpness. It is possible to sharpen the blade, but if there are damages or cracks, that deems them unusable. Don’t forget to check the rest of the tool, too.

- Is the blade locked into place? – It is particularly important to pay attention if you attached the blade to the saw properly. Depending on the tool, you will need to fasten it or use the locking mechanism to hold it into place.

- Pick a suitable blade – If you want to maximize the longevity of a cutting blade, it is imperative to use it only for suitable applications. That means you should always use the right diamond blade for the specific material you are cutting. Using a blade on wrong applications might shorten its lifespan and lead to damaging and cracking.

- No overheating allowed – the easiest way to damage a diamond saw blade is to overheat it. Not only that can destroy your blade and equipment, but it is also dangerous to you. That is why you should prevent overheating. You can do that by using a coolant like water, which the system would pour over the blade during the cutting process. Additionally, make sure to take breaks to allow the blade to cool down.

6. Safety Tips When Using a Diamond Saw Blade

If you are using saws equipped with blades, safety should be your primary concern. You don’t want anything to go wrong because that might mean serious equipment damage and potential injuries with severe consequences.

If you are using saws equipped with blades, safety should be your primary concern. You don’t want anything to go wrong because that might mean serious equipment damage and potential injuries with severe consequences.

Here is how to maximize safety when using a diamond saw blade:

- Always wear adequate safety equipment – there will be particles everywhere, so make sure to wear safety goggles. Additionally, you also need headgear, footwear, and other accessories. You should also consider respiratory equipment if you expect a lot of dust flying around.

- Each blade is specific – that is why you should always read the instructions provided by the manufacturer. The manual contains information on suitable applications and other details related to that particular tool. It is imperative to follow the instructions to maintain the maximum safety level.

- Never used damaged blades – we already mentioned you should check the state of the blade and the tool before you start using it. If there are any cracks or damages, never use the blade. Not only might you destroy the application and the desired cut, but that is highly unsafe for the operator.

- Make sure you are not in direct line with the blade. From the moment you start using the tool, ensure to steer clear of the blade’s way. Additionally, don’t experiment with using the blade’s sides to grind the materials.

- Never let the blade go – you must keep the saw safe in your hand while operating. However, don’t use excessive force on the material because you might cause damage or overheat.

- Take breaks during the dry cutting process – friction creates heat, and too much heat causes damage. If you don’t use a coolant, take breaks to let the blade cool down.

Final Thoughts

Ultimately, diamond saw blades are a beneficial piece of equipment perfect for handling hard materials. If you need to cut a tough application, such as concrete or marble, these are the blades you can count on at any time.

However, it is important to pick the right blade for the job. You can choose between various types of diamond saw blades, and you also need to consider other specifics of the equipment. Additionally, don’t forget safety and maintenance to maximize the longevity of your blade and make it a worthwhile long-term investment.

If you are looking for diamond saw blades of professional quality, you can buy them from NCCuttingTools. This customizable mass sales manufacturer specializes in designing reliable and durable diamond blades with quality that will exceed your expectations